It is a great idea to use furniture protectors, flooring mats, as well as area rugs to guard the wood floors of yours from scratches. An oak wood flooring is an excellent choice because it's so difficult and works effectively in areas which get a great deal of site traffic, but you can find a few things you ought to be conscious of before you choose the hardwood flooring of yours.

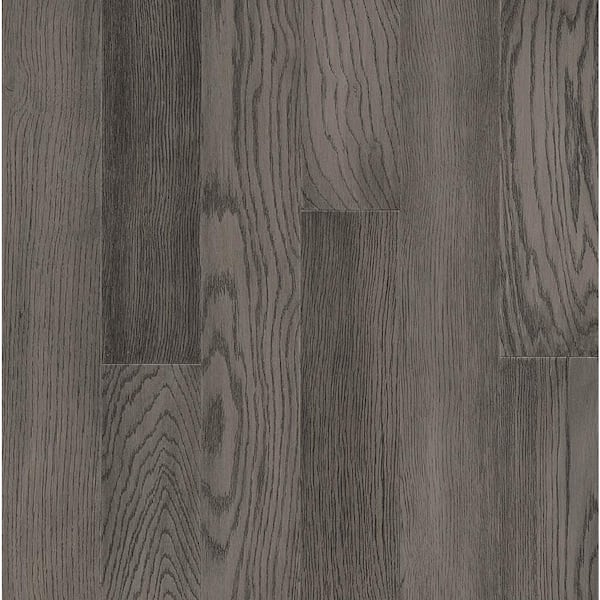

Images Related to Grey Wood Floors Engineered

Grey Wood Floors Engineered

This is an important step since the boards can be composed out of an all natural material, they must be allowed to acclimatise on the brand new room temperature as well as moisture levels they'll be exposed to. Since many laminates just click together without any glues it's right away to fit. Right now there are risk involved should you use wood in a kitchen or bathroom.

Style Selections Locking Hardwood Flooring Logan Gray Bamboo 5-1/8-in Wide x 3/8-in Thick Wirebrushed Engineered Hardwood Flooring (20.49-sq ft)

If you are looking to get into as well as finish off a house renovation project that will add a great deal of value to the home of yours, you need look no more rather than adding engineered wood flooring. The wood needs to be meticulously sawn to segregate the defects in a log or beam that may possibly have been rising for a number of 100 years. The following most popular is typically the unique style.

NATU Wide Plank 7-1/2 in. W Grey Smoked Engineered French Oak

Bruce Hydropel Oak Medium Gray 7/16 in. T x 5 in. W x Varying

Engineered Hardwood Oak City Grey Handscraped u0026 Distressed 6″ in

Wide Plank French Oak Wood Floor, Grey Ridge, Prefinished Engineered, Sample eBay

Gunmetal Vs. Grey Wood Flooring – How To Choose? – Wood and Beyond

Gray Wood Flooring Engineered Gray Hardwood Floors by LIFECORE®

Engineered Hardwood Oak Crest Grey Handscraped u0026 Distressed 6″ in

Rustic Engineered Wood Flooring Dark Grey Wood Flooring – China

Ash Grey Elegant Engineered Hardwood Los Angeles

Gray Curitiba Hickory Hand Scraped Engineered Hardwood Hardwood

NATU (Sample) XL SPC Wood Prefinished French Oak Grey Washed European White Oak Smooth/Traditional Engineered Hardwood Flooring Sample

Why You Should Choose Grey Hardwood Flooring – PurezaWood

Related articles:

- How Is Engineered Wood Flooring Made

- Wood Flooring For Kitchens Advice

- Width Of Wood Floor Planks

- Real Wood Flooring Cost Per Square Foot

- How Much Does Wood Flooring Cost Per Square Foot Installed

- Wood Floor Texture Map

- Light Wood Floors With Dark Kitchen Cabinets

- Pine Wood Floorboards

- Kitchen Wood Flooring Pros And Cons

- Do It Yourself Wood Floor Refinishing

Grey Wood Floors Engineered: The Perfect Blend of Elegance and Durability

Introduction:

Grey wood floors have become increasingly popular in interior design due to their ability to add a touch of sophistication and versatility to any space. Among the various options available, engineered grey wood floors have gained significant attention. Engineered grey wood floors offer the perfect blend of elegance and durability, making them an ideal choice for homeowners and designers alike. In this article, we will explore the features, benefits, installation process, maintenance tips, and frequently asked questions about grey wood floors engineered.

I. Features of Grey Wood Floors Engineered:

Engineered grey wood floors are crafted using multiple layers of real wood veneer that are cross-layered and bonded together. This unique construction technique enhances the stability and strength of the flooring while maintaining its natural beauty. The following features make engineered grey wood floors stand out:

1. Aesthetic Appeal:

Grey wood floors engineered exude timeless beauty with their soft, muted tones that effortlessly complement a wide range of interior styles. Whether you prefer a contemporary, rustic, or traditional look, these floors provide a neutral backdrop that allows other elements in your space to shine.

2. Versatility:

One of the greatest advantages of engineered grey wood floors is their versatility. They can be installed in any room, including high-moisture areas such as kitchens and bathrooms, thanks to their resistance to warping and moisture damage.

3. Durability:

Engineered grey wood floors are highly durable due to their construction. The multiple layers provide increased stability and resistance to fluctuations in temperature and humidity, making them less prone to expanding or contracting compared to solid hardwood floors.

4. Easy Maintenance:

Maintaining engineered grey wood floors is a breeze. Regular sweeping or vacuuming followed by occasional mopping with a damp cloth is all it takes to keep them looking pristine. Additionally, the factory-applied finishes on these floors provide added protection against stains and scratches.

II. Benefits of Grey Wood Floors Engineered:

The benefits of opting for grey wood floors engineered go beyond their aesthetic appeal and durability. Let’s delve deeper into the advantages they offer:

1. Cost-Effective:

Engineered grey wood floors are generally more cost-effective than solid hardwood floors. The multi-layered construction allows for the use of less expensive materials in the core layers while still providing the same visual appeal as solid wood.

2. Easy Installation:

Installing grey wood floors engineered is a relatively straightforward process, whether you choose to glue them down, float them, or use a click-lock system. The installation can be completed quickly and efficiently, saving you time and labor costs.

3. Environmental Sustainability:

Engineered grey wood floors are an eco-friendly choice as they utilize fewer hardwood trees compared to solid wood floors. The top layer of real wood veneer is typically sliced thin, making the most out of each tree while maintaining the luxurious appearance of solid wood.

4. Enhanced Stability:

Due to their unique construction, engineered grey wood floors are more dimensionally stable than solid hardwood floors. This stability makes them less susceptible to shrinkage or expansion caused by changes in humidity levels, ensuring that your floors maintain their original beauty for years to come.

III. Installation Process:

The installation process for grey wood floors engineered varies depending on the chosen method: glue-down, floating, or click-lock system. Let’s explore each method in detail:

1. Glue-Down Method:

In this method, the engineered grey wood planks are glued directly onto The subfloor using a strong adhesive. This method provides a stable and secure installation. The planks are carefully measured and cut to fit the space, ensuring a precise and seamless look. It is important to follow the manufacturer’s instructions for the specific adhesive and application process.

2. Floating Method:

In the floating method, the engineered grey wood planks are not attached to the subfloor but instead are interlocked with each other. This method is popular because it is relatively easy to install and allows for flexibility in case of any future changes or repairs. Underlayment is typically used to provide cushioning and noise reduction.

3. Click-Lock System:

The click-lock system is a type of floating installation that uses a tongue-and-groove mechanism to connect the planks together. The planks simply snap into place without the need for glue or nails. This method is known for its quick and efficient installation process, making it a popular choice among DIY enthusiasts.

Before starting the installation process, it is important to properly prepare the subfloor by ensuring it is clean, level, and dry. It may be necessary to remove any existing flooring or make any necessary repairs before proceeding with the installation.

Overall, the installation process for engineered grey wood floors can be relatively simple and straightforward, especially when compared to solid hardwood floors. However, it is always recommended to consult with a professional or follow the manufacturer’s guidelines for best results. Installing engineered grey wood floors offers several advantages, including durability, cost-effectiveness, environmental sustainability, and enhanced stability. The installation process can vary depending on the chosen method: glue-down, floating, or click-lock system.

The glue-down method involves applying a strong adhesive to the subfloor and then gluing the engineered grey wood planks directly onto it. This method ensures a stable and secure installation, with carefully measured and cut planks for a precise look.

The floating method does not attach the planks to the subfloor but instead interlocks them with each other. This method is popular because it allows for flexibility in case of future changes or repairs. Underlayment is typically used for cushioning and noise reduction.

The click-lock system is a type of floating installation where the planks connect using a tongue-and-groove mechanism. They simply snap into place without the need for glue or nails. This method is known for its quick and efficient installation process, making it popular among DIY enthusiasts.

Before beginning the installation process, it’s important to properly prepare the subfloor by ensuring cleanliness, levelness, and dryness. It may be necessary to remove existing flooring or make repairs before proceeding.

Overall, installing engineered grey wood floors can be relatively simple and straightforward when compared to solid hardwood floors. However, it’s always recommended to consult with a professional or follow manufacturer guidelines for best results. Installing engineered grey wood floors offers several advantages, including durability, cost-effectiveness, environmental sustainability, and enhanced stability. The installation process can vary depending on the chosen method: glue-down, floating, or click-lock system.

The glue-down method involves applying a strong adhesive to the subfloor and then gluing the engineered grey wood planks directly onto it. This method ensures a stable and secure installation, with carefully measured and cut planks for a precise look.

The floating method does not attach the planks to the subfloor but instead interlocks them with each other. This method is popular because it allows for flexibility in case of future changes or repairs. Underlayment is typically used for cushioning and noise reduction.

The click-lock system is a type of floating installation where the planks connect using a tongue-and-groove mechanism. They simply snap into place without the need for glue or nails. This method is known for its quick and efficient installation process, making it popular among DIY enthusiasts.

Before beginning the installation process, it’s important to properly prepare the subfloor by ensuring cleanliness, levelness, and dryness. It may be necessary to remove existing flooring or make repairs before proceeding.

Overall, installing engineered grey wood floors can be relatively simple and straightforward when compared to solid hardwood floors. However, it’s always recommended to consult with a professional or follow manufacturer guidelines for best results.