So hopefully this can enable you to make your mind up whether the floor of yours is sanded and refurbished or perhaps if it is time to replace it. When you discover huge pets or children in the home, you will want to consider checking out a laminate floor, which is considerably more reluctant to scratches. This is made from excessive density fibre, mdf underlayering or hardened plastics, is a very popular flooring choice.

Images Related to How Is Engineered Wood Flooring Made

How Is Engineered Wood Flooring Made

/cdn.vox-cdn.com/uploads/chorus_asset/file/19489671/02_about_wood_floors_x.jpg)

While you're getting responses to those questions, bear in mind in case you have the flooring professionally installed, you will save relationships that you've along with the family and friends that you were gon na seek to help you using this type of task. You'll find a variety of kinds of genuine wood flooring, every one with a look that is completely its own.

ENGINEERED WOOD FLOOR An Architect Explains And Reviews

Allow me to share some pointers to assist you work out what kind of flooring you've. A normal budget range for labor as well as supplies to install a wood floor is $4-5 per square foot. A number of individuals love to hold back until their wood floor is in their homes before choosing a finish while others love to have their floor ready and raring to go so they can utilize it once it's fitted.

How is Engineered Flooring Made Woodpecker Flooring

What is Engineered Wood Flooring? Engineered Hardwood

How Is Hardwood Flooring is Made? BuildDirect Learning

How is Engineered Hardwood Made

How to Lay Engineered Wood Floors – This Old House

/cdn.vox-cdn.com/uploads/chorus_asset/file/19494392/floor_5.jpg)

Engineered Hardwood u2013 Honest Home

All About Engineered Wood Flooring

Engineered Flooring Guide Engineered Floors FlooringSupplies.co.uk

Hardwood Vs. Engineered Wood Flooring u2013 Which Is Best For You

The Definitive Guide to Engineered Wood Floors

Solid vs. Engineered – Quality Hardwoods, Superior Design Palo

Solid Wood vs. Engineered Wood Flooring Comparison Guide

/engineered-hardwood-vs-solid-flooring-1821677_hero_0203-f8f7a371474d4e24b733fec5edfc46fc.jpg)

Related articles:

- Engineered Wood Flooring Grades

- Cheap Wood Flooring And Fitting

- Engineered Wood Flooring Adhesive Reviews

- Easy Click Wood Flooring

- Wood Flooring Types Pergo

- Wood Floor Installation Pattern

- Astonish Flawless Wood Floor Polish

- Real Wood Flooring Installation

- Can Engineered Wood Flooring Be Sanded And Refinished

- Kahrs Wood Flooring Cleaner

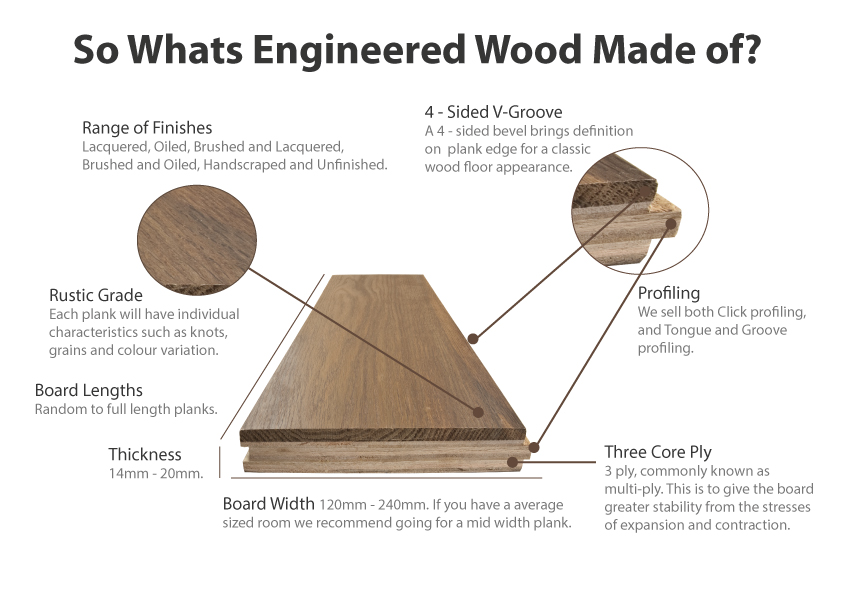

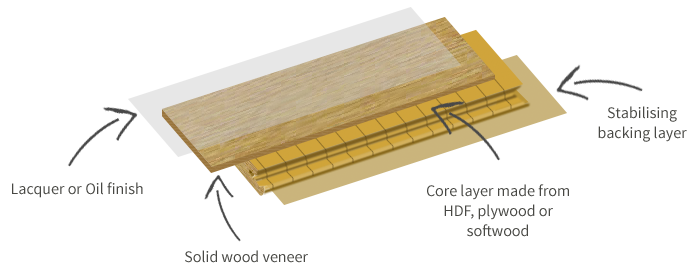

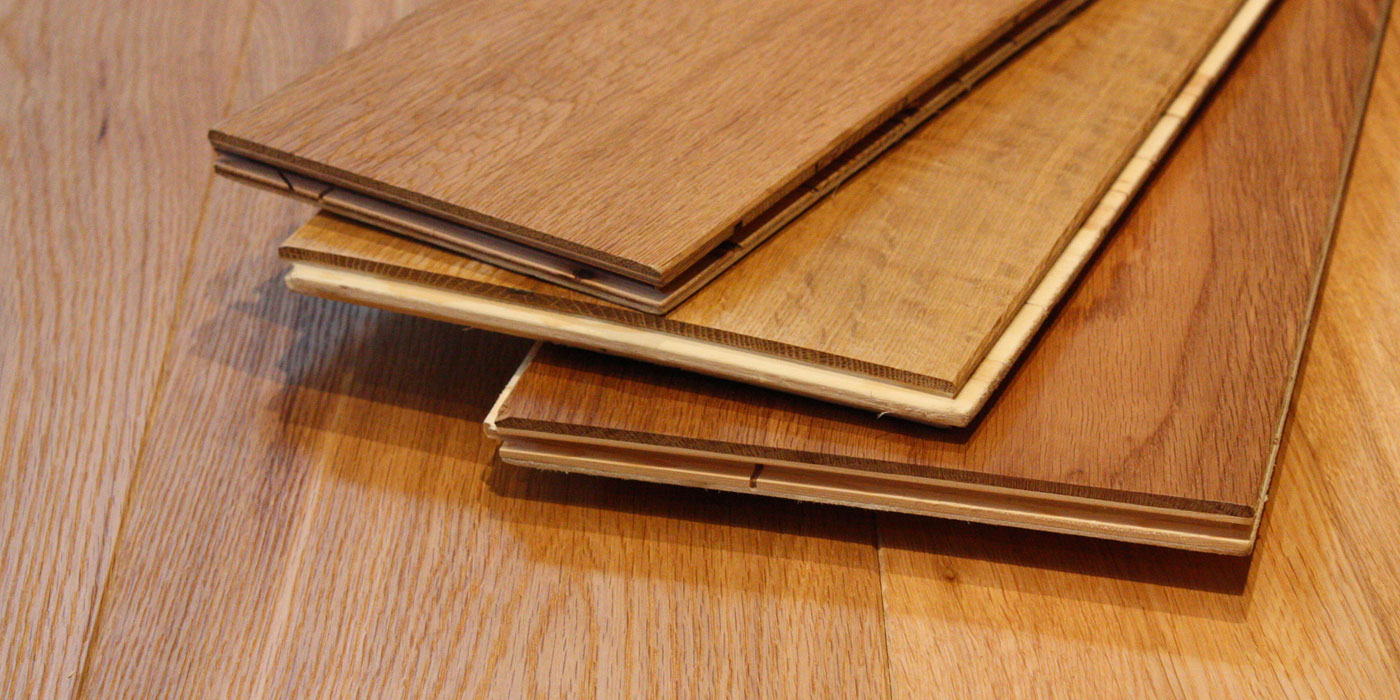

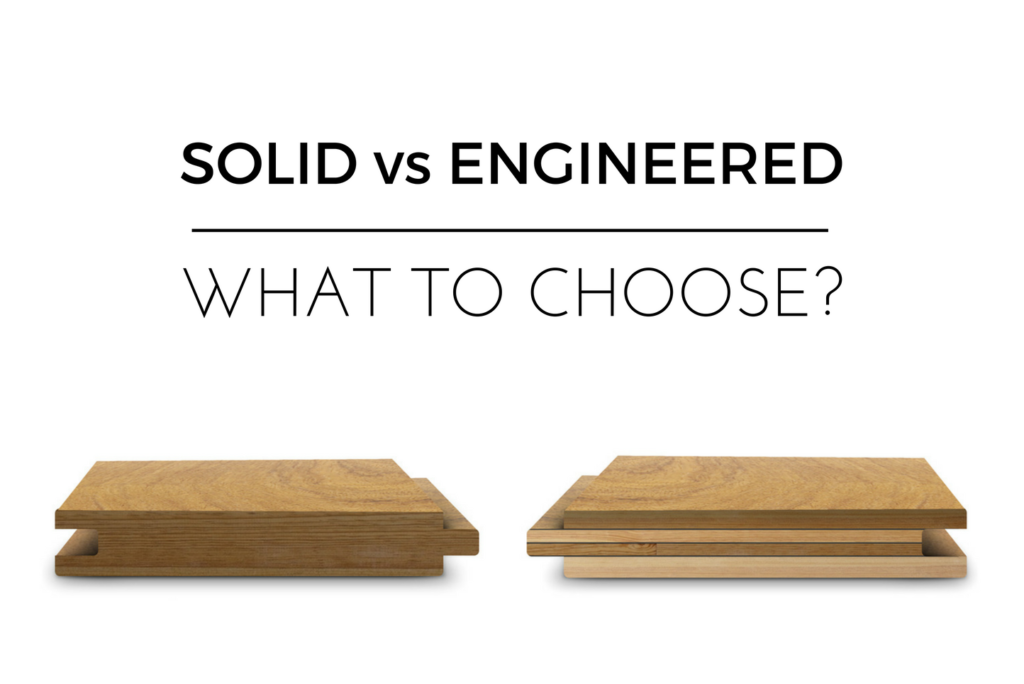

Engineered wood flooring has become a popular choice for homeowners looking to add the warmth and beauty of wood to their homes. This type of flooring is made from layers of real wood veneer, with each layer stacked in a cross-grain pattern and bonded together under heat and pressure. In this article, we will explore the process of how engineered wood flooring is made, from the selection of raw materials to the finished product.

Selection of Raw Materials:

The first step in the manufacturing process of engineered wood flooring is the selection of raw materials. High-quality hardwood veneer is typically used for the top layer of the flooring, while cheaper woods or softwoods are used for the core layers. The core layers are usually made from plywood or high-density fiberboard (HDF) to provide stability and strength to the flooring.

FAQ: What types of wood are commonly used for the top layer of engineered wood flooring?

Answer: Common hardwood species used for the top layer of engineered wood flooring include oak, maple, cherry, and walnut. These species are chosen for their durability and aesthetic appeal.

Preparation of Veneer Layers:

Once the raw materials have been selected, the next step is to prepare the veneer layers. The hardwood veneer is sliced from logs using a rotary cutting machine or a slicing machine. The veneer is then dried to remove moisture and prevent warping before being glued together to form a single sheet.

FAQ: Why is it important to dry the veneer before gluing it together?

Answer: Drying the veneer helps to stabilize the wood and prevent it from expanding or contracting after it has been glued together. This ensures that the engineered wood flooring remains flat and uniform throughout its lifespan.

Bonding Layers Together:

After the veneer layers have been prepared, they are bonded together using an adhesive. The adhesive used in this process is typically a strong, waterproof glue that can withstand temperature changes and high levels of humidity. The layers are pressed together under heat and pressure to create a strong bond between them.

FAQ: Is there a difference between plywood-core and HDF-core engineered wood flooring?

Answer: Plywood-core engineered wood flooring is generally more stable and durable than HDF-core flooring. However, HDF-core flooring is typically more affordable and easier to install.

Adding Finishing Touches:

Once the layers have been bonded together, the engineered wood planks are cut into standard sizes and shapes using precision cutting equipment. The edges of the planks are then beveled or micro-beveled to create a seamless transition between each piece. Finally, a protective finish is applied to the surface of the planks to enhance their durability and resistance to wear and tear.

FAQ: What types of finishes are commonly used on engineered wood flooring?

Answer: Common finishes for engineered wood flooring include polyurethane, aluminum oxide, and oil-based finishes. These finishes provide varying levels of protection against scratches, stains, and fading.

Quality Control Testing:

Before being packaged and shipped to retailers, engineered wood flooring undergoes rigorous quality control testing to ensure that it meets industry standards for durability and performance. Samples of the flooring are subjected to stress tests, moisture tests, and other quality checks to identify any defects or imperfections that may affect its longevity.

FAQ: How can I tell if an engineered wood floor meets industry standards for quality?

Answer: Look for products that have been certified by reputable organizations such as the Forest Stewardship Council (FSC) or the National Wood Flooring Association (NWFA). These Certifications indicate that the product has been manufactured using sustainable practices and meets high standards for quality and performance. Additionally, reading customer reviews and asking for recommendations from flooring experts can also help you determine the quality of a particular engineered wood flooring product. Overall, the process of manufacturing engineered wood flooring involves drying the veneer, bonding layers together with adhesive, adding finishing touches, and undergoing quality control testing to ensure durability and performance. Plywood-core flooring is typically more stable and durable than HDF-core flooring, but HDF-core flooring is more affordable and easier to install. Common finishes for engineered wood flooring include polyurethane, aluminum oxide, and oil-based finishes. Look for certifications from reputable organizations like the FSC or NWFA to ensure that the product meets industry standards for quality. Reading customer reviews and seeking recommendations from experts can also help you choose a high-quality engineered wood flooring product. Additionally, it is important to consider the thickness of the top veneer layer when choosing engineered wood flooring. A thicker veneer layer means that the floor can be sanded and refinished multiple times, extending its lifespan. Thicker veneer layers are also more resistant to denting and scratching.

Overall, engineered wood flooring is a versatile and durable option for homeowners looking for the beauty of hardwood with added stability and resistance to moisture. By understanding the manufacturing process and quality control measures, you can make an informed decision when selecting engineered wood flooring for your home.