The expression that relates to a selection of decorative concrete flooring choices that typically end up leaving a concrete surface area preferably exposed while the previous final as well as last floor finishing. For an intensive cleaning, wash the floor with a concrete cleaner and then follow with a good rinsing. Little bumps and ridges are made on textured concrete floor surfaces for an improved traction while walking.

Here are Images about Fixing Ply To Concrete Floor

Fixing Ply To Concrete Floor

The floor could be dyed almost any color and area glow can be anyplace between a matte finish to a higher gloss. Those who are susceptible to allergies can safely make use of concrete flooring in their house. Technological advances have prepared polished concrete floor one particular of the good opposition and at existing, you are able to anticipate get some spectacular floors.

Installing Wood Flooring Over Concrete (DIY)

Nevertheless, the issue with DIY floors concreting is you might not have the ability to mix an actual proportion for the cement and water combination and often will result in a terrible consequence. Concrete floors polishing can turn the surface area into an elegant floor. Concrete flooring looks good of residences as it blends well with home furnishing.

Images Related to Fixing Ply To Concrete Floor

How to Attach plywood to concrete as a floor base « Construction

Can You Put Plywood Over Concrete – Ready To DIY

How-to install a wood subfloor over concrete RONA

How to attach wood to a concrete floor IN SECONDS! How to attach 2×4 wood to concrete floor fast!

Qu0026A: Solid Wood Floors Over Concrete Slabs JLC Online

How to Make Subfloor Leveling with Plywood and Concrete Self Leveling Compound MrYoucandoityourself

Installing a Hardwood Floor Over a Concrete Slab – American

Concrete over a plywood subfloor with 16″ on center floor joists

Can You Put Plywood Over Concrete – Ready To DIY

How to Install a Wood Subfloor Over Concrete Olde Wood Ltd.

6 Ways to Fix Uneven Subfloor or Concrete Slabs u2013 Home Inspection

Installing Wood Subfloors Over Concrete – Hardwood Floors Magazine

Related articles:

- Concrete Floor Resin Coating

- Concrete Floor Paint Preparation

- Stained Concrete Floor Designs

- How To Paint A Concrete Floor Inside

- Concrete Floor In Garage

- Polished Concrete Floor Ideas

- Gypsum Concrete Floor Underlayment

- Polishing Concrete Floor By Hand

- Concrete Floor Paint Prep

- Polished Concrete Floors For Patios

Fixing Ply to Concrete Floor: A Comprehensive Guide

Introduction:

When it comes to flooring options, concrete floors are known for their durability and low maintenance. However, they can be unforgivingly hard and cold, making them less desirable in certain environments. To address this issue, many homeowners and builders choose to fix ply (plywood) on top of the concrete floor. This not only provides a warmer and more comfortable surface but also allows for various flooring options such as carpet, vinyl, or laminate to be installed. In this article, we will provide you with a detailed guide on how to fix ply to a concrete floor, along with common FAQs and their answers.

I. Preparation:

Before fixing ply to a concrete floor, it is crucial to prepare the surface properly. This step ensures that the installation is successful and that the ply adheres securely to the concrete. Follow these steps for effective preparation:

1. Clean the Concrete Surface: Start by removing any debris, dirt, or loose particles from the concrete floor. Sweep thoroughly and use a vacuum cleaner if necessary. Additionally, consider using a degreaser or detergent solution to remove any stubborn stains or grease spots.

2. Fill in Cracks and Holes: Inspect the concrete floor for any cracks or holes. If you find any, use an appropriate filler compound to level them out. Allow sufficient drying time before moving forward.

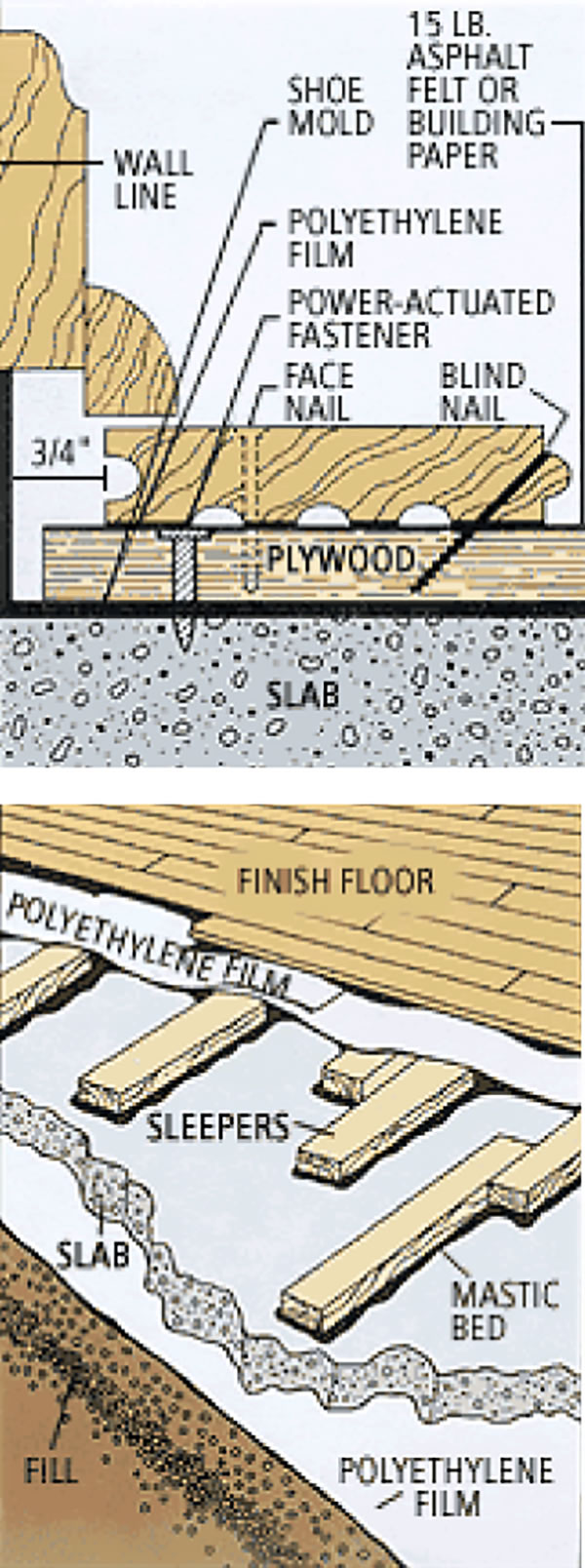

3. Moisture Testing: Moisture can be a significant concern when fixing ply to a concrete floor, as excess moisture can cause damage to both materials. Perform a moisture test using a moisture meter or plastic sheet method to determine if there are any moisture issues present. If high levels of moisture are detected, it is essential to address them before proceeding with the installation.

FAQs:

Q1: Why is moisture testing necessary before fixing ply on a concrete floor?

A1: Moisture testing helps identify if there is excess moisture in the concrete, which can lead to warping or delamination of the ply. It is crucial to address these issues before installation to ensure optimal results and prevent any potential damage.

Q2: What should I do if moisture levels are high?

A2: If high moisture levels are detected, it is recommended to use a moisture barrier or damp-proof membrane on the concrete floor. This helps create a protective layer between the concrete and ply, preventing moisture from seeping through.

II. Choosing Plywood:

Selecting the right type of plywood is essential for a successful installation. Here are a few factors to consider when choosing ply for fixing it to a concrete floor:

1. Moisture Resistance: Opt for plywood specifically designed for moisture-prone areas, such as basements or bathrooms. Moisture-resistant plywood, commonly known as marine plywood, is an excellent choice as it has enhanced water resistance properties.

2. Thickness: The thickness of the plywood depends on various factors, including the subfloor condition and the desired flooring type. Generally, 3/4-inch thick plywood is recommended for most applications.

3. Quality and Grading: Choose high-quality plywood with minimal defects and a good grading system. Look for plywood labeled as “Exterior” or “Exposure 1,” which indicates its suitability for exterior and wet area applications.

FAQs:

Q1: Can I use regular plywood instead of moisture-resistant plywood?

A1: While regular plywood can be used in certain situations, it is generally advisable to opt for moisture-resistant plywood when fixing it to a concrete Floor. Moisture-resistant plywood is specifically designed to withstand moisture and is less likely to warp or delaminate when exposed to high levels of moisture. Using regular plywood may result in damage and a shorter lifespan of the flooring.

Q2: Is thicker plywood always better?

A2: The thickness of the plywood depends on various factors such as the subfloor condition and the desired flooring type. Thicker plywood can provide more stability and support, but it may not always be necessary. It is essential to consider the specific requirements of your project and consult with a professional if needed.

III. Installation Process:

Once you have prepared the concrete floor and chosen the right type of plywood, you can proceed with the installation process. Here are the steps to follow:

1. Acclimation: Allow the plywood to acclimate to the room’s temperature and humidity for at least 48 hours before installation. This helps prevent any potential warping or expansion after installation.

2. Apply Adhesive: Use a suitable adhesive recommended for plywood-to-concrete installations. Apply the adhesive evenly on the concrete floor using a trowel or roller, ensuring full coverage.

3. Lay Plywood: Place the plywood sheets on top of the adhesive, starting from one corner of the room. Leave a small gap between sheets for expansion, usually around 1/8 inch. Use screws or nails to secure the plywood to the concrete floor, following manufacturer guidelines.

4. Fill Joints: Fill any gaps or joints between plywood sheets using a wood filler or caulk specifically designed for flooring applications. This helps create a smooth and even surface.

5. Sand and Finish: Once the adhesive has fully cured and the plywood is firmly secured, sand the surface to remove any imperfections and create a smooth finish. Apply your desired flooring material, such as hardwood or laminate, following the manufacturer’s instructions.

FAQs:

Q1: Can I install plywood directly on a concrete floor without adhesive?

A1: It is not recommended to install plywood directly on a concrete floor without adhesive. Adhesive helps create a strong bond between the plywood and concrete, ensuring stability and preventing shifting or movement over time.

Q2: How long does it take for the adhesive to cure?

A2: The curing time for the adhesive can vary depending on the specific product used. It is important to refer to the manufacturer’s instructions for recommended curing times. Generally, it can take anywhere from 24 to 72 hours for the adhesive to fully cure before proceeding with further steps.

Q3: Can I install plywood over a painted concrete floor?

A3: It is generally not recommended to install plywood over a painted concrete floor. The paint can create a barrier that prevents proper bonding between the adhesive and the concrete, leading to potential issues with stability and durability. It is best to remove any existing paint before installing plywood.

Q4: Do I need to use a moisture barrier under the plywood?

A4: In some cases, it may be necessary to use a moisture barrier under the plywood to prevent moisture from seeping through and causing damage. This is especially important in areas with high humidity levels or if there are concerns about moisture coming up from the concrete subfloor. Consult with a professional or follow manufacturer guidelines to determine if a moisture barrier is necessary for your specific installation.

Q5: Can I install plywood directly on a concrete floor in a basement?

A5: Installing plywood directly on a concrete floor in a basement can be problematic due to potential moisture issues. Basements tend to have higher levels of humidity and moisture, which can cause the plywood to warp or rot over time. It is recommended to use moisture barriers, proper insulation, and consult with professionals when considering installing plywood in a basement.