You will find a range of different strategies you can apply to concrete flooring to produce gorgeous decorative floors suitable for both your workplace and the home of yours. If you want to drive a tank of it, once poured, concrete should take it. With acid stained concrete floors, you've options available to meet the design must have of yours.

Here are Images about Concrete Floor Systems Residential Construction

Concrete Floor Systems Residential Construction

Once the concrete floor is clean and ready for its coating, it all boils down to timing. The floor at the medical center or perhaps food store may look glossy, attractive and very unique; this's only since it is a polished concrete floors. Polished concrete flooring offers a great visual sight while maintaining a feeling of style & uniqueness about it.

Insulated Concrete Floors u2022 Insul-Deck Insulated Concrete Forms

The spectacular surge in each science as well as technology have added array of flooring alternatives for the builders along with homeowners, and also seems that concrete polish flooring is actually one of the latest and hottest alternatives among others. Concrete flooring these days has developed into a brand new flooring option for homeowners and designers around the globe.

Images Related to Concrete Floor Systems Residential Construction

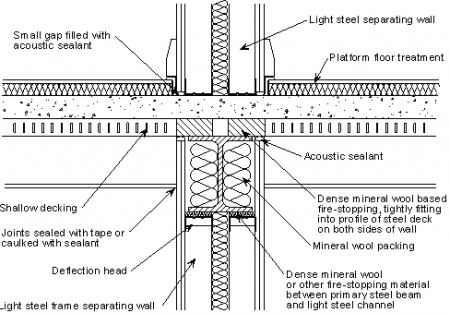

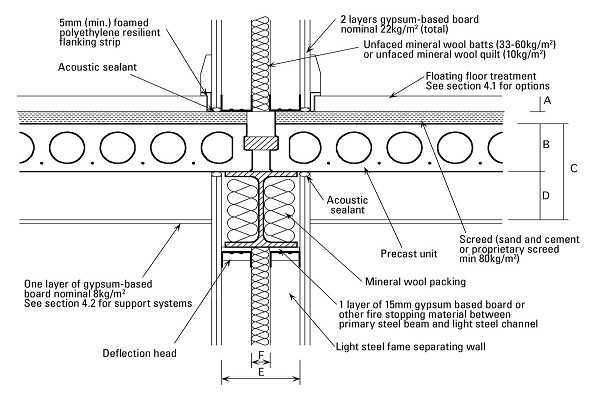

Floor systems – SteelConstruction.info

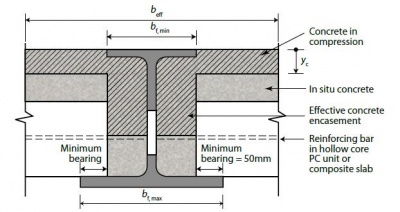

Precast Concrete Floor Systems Types Of Precast Concrete Floors

Lighter, Stronger Precast Concrete Floor System – NPCA

Floor systems – SteelConstruction.info

Concrete Slab on Metal Deck Floor Systems – Architecture

Lightweight Concrete Floor Systems – Thickness, Uses – The Constructor

Steel Decking for Concrete Floors, Ecospan, Get More for Less

Floor systems – SteelConstruction.info

Concrete Floor Systems Dimensions u0026 Drawings Dimensions.com

Pin on Ideas for the House

Unique Suspended Concrete Flooring Systems SpeedFloor USA

Concrete Slab Types – Construction, Cost, and Applications – The

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Concrete Floor Systems in Residential Construction: A Comprehensive Guide

Introduction:

In the realm of residential construction, concrete floor systems have emerged as a popular choice due to their durability, versatility, and aesthetic appeal. Whether used in basements, garages, or main living areas, concrete floors offer homeowners a range of benefits. This article will delve into the various aspects of concrete floor systems in residential construction, exploring their types, installation process, maintenance requirements, and more.

I. Types of Concrete Floor Systems

Concrete floors come in different types to cater to the specific needs and preferences of homeowners. Let’s take a closer look at some common options:

1. Traditional Poured Concrete Floors:

Traditional poured concrete floors are created by pouring a mixture of cement, water, and aggregates onto a prepared subfloor. This method provides a solid foundation and allows for customization through decorative treatments such as staining or stamping.

FAQ: Are traditional poured concrete floors suitable for all residential applications?

Answer: Yes, traditional poured concrete floors are suitable for various residential applications. However, they might not be the best option for areas prone to extreme temperature changes as they can crack under such conditions.

2. Polished Concrete Floors:

Polished concrete floors offer a sleek and modern aesthetic while providing excellent durability. This type of flooring involves grinding down the surface of the poured concrete and applying a series of polishing steps to achieve a smooth finish.

FAQ: Can polished concrete floors be slippery?

Answer: While polished concrete floors may appear smooth, they can be treated with non-slip coatings or additives to enhance traction and reduce the risk of slipping.

3. Stained Concrete Floors:

Stained concrete floors add depth and character to any residential space. By applying acid-based stains or water-based dyes, homeowners can achieve a wide range of colors and patterns that mimic natural stone or create unique designs.

FAQ: Will stained concrete floors fade over time?

Answer: Properly sealed stained concrete floors should resist fading. However, exposure to direct sunlight or harsh chemicals may cause some color variation over an extended period. Regular maintenance and resealing can help maintain the floor’s appearance.

4. Concrete Overlays:

Concrete overlays are a cost-effective solution for revitalizing old or damaged floors. This method involves applying a thin layer of concrete onto the existing surface, providing a fresh and updated appearance without the need for complete removal and replacement.

FAQ: Can concrete overlays be applied on top of existing tile or hardwood floors?

Answer: Yes, concrete overlays can be applied over various surfaces, including tile or hardwood floors, as long as the existing flooring is in good condition and properly prepared.

II. Installation Process of Concrete Floor Systems

The installation of concrete floor systems involves several key steps to ensure a sturdy and long-lasting result. Let’s explore these steps in detail:

1. Site Preparation:

Before pouring the concrete, site preparation is crucial to ensure proper drainage and prevent future issues. The area must be excavated, removing any vegetation, loose soil, or debris. Additionally, proper grading should be carried out to promote water runoff.

2. Subfloor Preparation:

Once the site is ready, it’s essential to prepare the subfloor for the concrete application. This typically involves cleaning the surface thoroughly and applying a layer of primer or bonding agent to enhance adhesion between the subfloor and concrete.

3. Formwork Construction:

Formwork is used to shape and contain the poured concrete until it cures. It consists of temporary structures made of wood, metal, Or plastic that are constructed around the perimeter of the area where the concrete will be poured. The formwork must be properly aligned and secured to ensure the concrete maintains its desired shape and thickness.

4. Reinforcement Placement:

Depending on the specific requirements of the project, reinforcement may be necessary to enhance the strength and durability of the concrete floor. This can include the installation of rebar or wire mesh within the formwork to provide added support.

5. Concrete Pouring:

Once all preparations are complete, the concrete can be poured into the formwork. It’s important to ensure an even and consistent pour, taking care to avoid air pockets or voids. The concrete should be leveled and smoothed out using tools such as screeds, floats, and trowels.

6. Curing and Finishing:

After the concrete has been poured, it must be allowed to cure for a specified period of time to gain strength and durability. During this time, it’s important to protect the concrete from excessive moisture loss or rapid drying. Once cured, various finishing techniques can be applied, such as polishing, staining, or sealing, to achieve the desired aesthetic and functionality.

7. Maintenance:

To ensure the longevity and performance of a concrete floor system, regular maintenance is essential. This can include routine cleaning, resealing as needed, and addressing any repairs or damages promptly. Following proper maintenance practices will help preserve the appearance and functionality of the concrete floor for years to come.

In conclusion, concrete floors offer a versatile and durable solution for residential spaces. With various options such as polished concrete, stained concrete, and overlays, homeowners can achieve their desired aesthetic while enjoying the benefits of a long-lasting and low-maintenance flooring system. The installation process involves careful site preparation, subfloor preparation, formwork construction, reinforcement placement, concrete pouring, curing and finishing, and regular maintenance to ensure optimal results. Concrete floors are a popular choice for residential spaces due to their versatility and durability. The installation process involves several steps to ensure optimal results.

1. Site Preparation:

Before installing a concrete floor, the site must be prepared properly. This may involve removing any existing flooring, clearing the area of debris, and ensuring that the subfloor is clean and level.

2. Subfloor Preparation:

Once the site is prepared, the subfloor must be properly prepared for the concrete application. This typically involves cleaning the surface thoroughly and applying a layer of primer or bonding agent to enhance adhesion between the subfloor and concrete.

3. Formwork Construction:

Formwork is used to shape and contain the poured concrete until it cures. It consists of temporary structures made of wood, metal, or plastic that are constructed around the perimeter of the area where the concrete will be poured. The formwork must be properly aligned and secured to ensure the concrete maintains its desired shape and thickness.

4. Reinforcement Placement:

Depending on the specific requirements of the project, reinforcement may be necessary to enhance the strength and durability of the concrete floor. This can include the installation of rebar or wire mesh within the formwork to provide added support.

5. Concrete Pouring:

Once all preparations are complete, the concrete can be poured into the formwork. It’s important to ensure an even and consistent pour, taking care to avoid air pockets or voids. The concrete should be leveled and smoothed out using tools such as screeds, floats, and trowels.

6. Curing and Finishing:

After the concrete has been poured, it must be allowed to cure for a specified period of time to gain strength and durability. During this time, it’s important to protect the concrete from excessive moisture loss or rapid drying. Once cured, various finishing techniques can be applied, such as polishing, staining, or sealing, to achieve the desired aesthetic and functionality.

7. Maintenance:

To ensure the longevity and performance of a concrete floor system, regular maintenance is essential. This can include routine cleaning, resealing as needed, and addressing any repairs or damages promptly. Following proper maintenance practices will help preserve the appearance and functionality of the concrete floor for years to come.

In conclusion, concrete floors offer a versatile and durable solution for residential spaces. With various options such as polished concrete, stained concrete, and overlays, homeowners can achieve their desired aesthetic while enjoying the benefits of a long-lasting and low-maintenance flooring system. The installation process involves careful site preparation, subfloor preparation, formwork construction, reinforcement placement, concrete pouring, curing and finishing, and regular maintenance to ensure optimal results.