Staining is actually probably the most common method put on to concrete flooring, acid stains are exclusively put on to the floor to create heavy rich colours. Polished concrete flooring offers a slew of amazing benefits to home builders and renovators. You are able to make many geometric shapes as well as designs to create basically any patent which you want. The natural color capabilities of concrete will accentuate some color scheme.

Here are Images about Concrete Floor Support System

Concrete Floor Support System

The primary reason is that these floors are power efficient flooring options and can last for a lot of years. The most difficult thing is waiting: Once the entire concrete floor is completed, you still need to hold off auto parking the automobile on it for another 72 hours. There are concrete floors which seem plain and gray just love those found in garages and factories.

Shoring Support for Concrete Slabs – EFCO Formwork Solutions

Stained concrete floors are actually stained with colors to match any decoration. When certain dust collects on the polished concrete floor, it is far better to lightly clean it all before it is able to gather to amounts which will require a little scrubbing of sorts. Once the chemical reaction requires place, staining concrete floors repair a permanent bond with the concrete and will not peel away.

Images Related to Concrete Floor Support System

Shoring Support for Concrete Slabs – EFCO Formwork Solutions

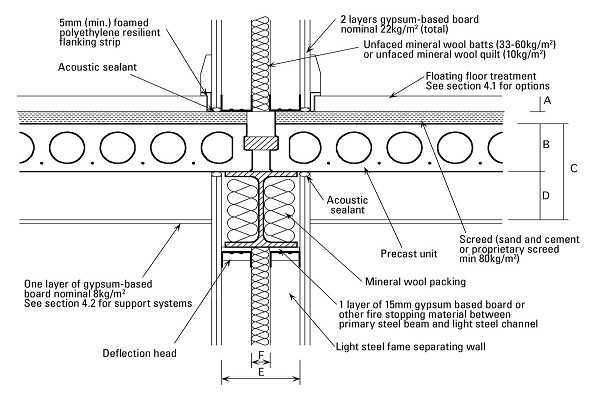

Precast Concrete Floor Systems Types Of Precast Concrete Floors

Lighter, Stronger Precast Concrete Floor System – NPCA

Floor Support Jacks

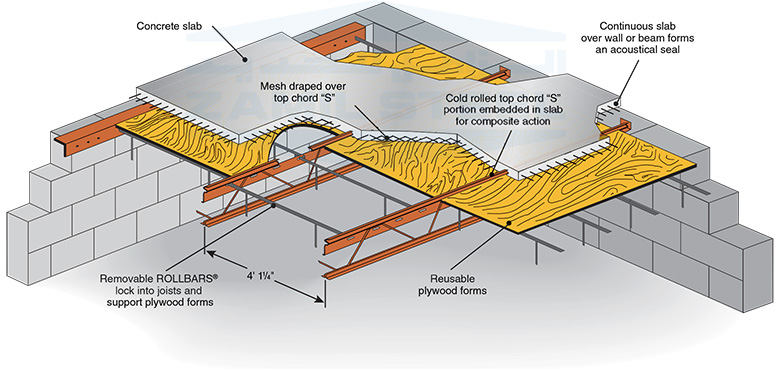

HAMBRO D500 Composite Floor System

concrete formwork for slabs

concrete formwork for slabs

Steel Decking for Concrete Floors, Ecospan, Get More for Less

Shoring Support for Concrete Slabs – EFCO Formwork Solutions

This Innovative Concrete Slab System Uses up to 55% Less Concrete

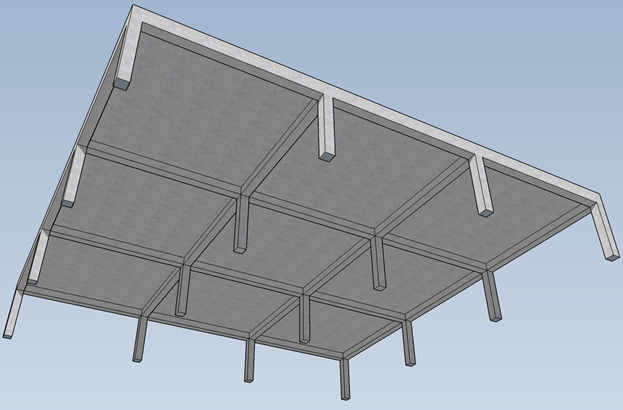

Two-Way Concrete Slab with Beams Spanning Between Supports

Concrete Floor Systems Dimensions u0026 Drawings Dimensions.com

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Concrete Floor Support System: Enhancing Structural Integrity and Stability

Introduction:

A well-designed and properly constructed concrete floor is essential for the structural integrity and stability of any building. The concrete floor support system plays a crucial role in distributing the weight of the structure effectively and ensuring its long-term durability. In this article, we will explore the various aspects of a concrete floor support system, including its components, types, installation process, maintenance, and frequently asked questions.

I. Understanding the Concrete Floor Support System

The concrete floor support system consists of several components that work together to provide stability and strength to the flooring structure. These components include:

1. Subgrade Preparation:

Before installing the concrete floor support system, it is vital to prepare the subgrade properly. This involves removing any vegetation, loose soil, or debris from the construction site. Additionally, compacting the soil to achieve a uniform density is crucial to prevent future settlement issues.

2. Base Material:

The base material acts as a foundation for the concrete floor support system. It is typically made of compacted gravel or crushed stone, providing a stable surface for the concrete slab to rest upon. The selection of appropriate base material depends on factors such as soil conditions, load-bearing requirements, and local building codes.

3. Reinforcement:

Reinforcement in the form of steel bars or fibers is commonly incorporated into concrete floors to enhance their strength and prevent cracking. The reinforcement helps distribute loads evenly across the slab and provides resistance against bending forces. It also helps control shrinkage cracking that may occur due to temperature variations.

FAQs:

Q1: Why is subgrade preparation important for a concrete floor support system?

A1: Proper subgrade preparation ensures a stable foundation for the flooring structure, preventing settlement issues and potential damage in the future.

Q2: What are the advantages of using reinforcement in concrete floors?

A2: Reinforcement improves the structural strength of the floor, reduces cracking, and enhances load-bearing capacity, ensuring a longer service life.

II. Types of Concrete Floor Support Systems

There are various types of concrete floor support systems available, each designed to meet specific construction needs. Some common types include:

1. Slab-on-Grade:

The slab-on-grade system is the most common and straightforward type of concrete floor support system. It involves pouring a single layer of concrete directly onto the prepared subgrade. This type of system is suitable for residential and light commercial applications.

2. Suspended Slab:

In certain cases, a suspended slab may be required when additional space is needed beneath the concrete floor. This type of system incorporates beams or joists to support the slab above, creating an elevated platform. Suspended slabs are often used in multi-story buildings or areas where utilities need to be concealed.

3. Post-Tensioned Slab:

Post-tensioned slabs use high-strength steel cables or tendons that are tensioned after the concrete has cured. This process allows for greater control over deflection and cracking, making it ideal for large-span structures such as parking garages and industrial facilities.

FAQs:

Q1: What factors should be considered when choosing a concrete floor support system?

A1: Factors such as building type, load requirements, site conditions, and budget should be considered to determine the most appropriate support system.

Q2: What are the advantages of using a post-tensioned slab?

A2: Post-tensioned slabs offer greater flexibility in design, reduced cracking, improved Structural performance, and the ability to span larger distances without the need for additional support columns. They also provide increased durability and longevity compared to other types of concrete floor support systems. Q3: Can a suspended slab be used in residential buildings?

A3: Yes, a suspended slab can be used in residential buildings, especially when additional space is needed beneath the concrete floor or when utilities need to be concealed.

Q4: Are there any disadvantages of using post-tensioned slabs?

A4: Some disadvantages of post-tensioned slabs include higher construction costs and the need for specialized expertise during installation and maintenance. Additionally, if not properly designed or maintained, post-tensioned slabs can experience corrosion issues over time.

Q5: Can reinforcement be added to all types of concrete floor support systems?

A5: Yes, reinforcement can be added to all types of concrete floor support systems. It helps enhance the strength and durability of the floor, regardless of the chosen support system.

Q6: Are there any specific maintenance requirements for different types of concrete floor support systems?

A6: Maintenance requirements may vary depending on the type of concrete floor support system. Regular inspections, repairs of any cracks or damages, and proper cleaning are generally recommended for all types of systems to ensure their longevity and structural integrity.

Q7: Can different types of concrete floor support systems be combined in a single building?

A7: Yes, different types of concrete floor support systems can be combined in a single building. For example, a building may have slab-on-grade floors on lower levels and suspended slabs on upper levels where additional space is required.

Q8: Can post-tensioned slabs be used in smaller structures such as houses?

A8: Yes, post-tensioned slabs can be used in smaller structures such as houses. However, they are more commonly used in larger structures with longer spans due to their cost-effectiveness and ability to handle greater loads without additional support columns.

What are the advantages of using a concrete floor support system?

There are several advantages of using a concrete floor support system:1. Durability: Concrete is known for its strength and durability, making it an ideal material for floor support systems. It can withstand heavy loads and is resistant to wear and tear, making it suitable for high-traffic areas.

2. Fire resistance: Concrete is non-combustible and has a high fire resistance rating, making it a safer option compared to other materials like wood. This can be particularly important in commercial or industrial settings where fire safety is a concern.

3. Sound insulation: Concrete has excellent sound insulation properties, reducing noise transmission between floors. This can be beneficial in residential or commercial buildings where noise reduction is desired.

4. Thermal mass: Concrete has high thermal mass, which means it can absorb, store, and release heat slowly. This helps regulate temperature fluctuations and can contribute to energy efficiency by reducing heating and cooling needs.

5. Versatility: Concrete floor support systems can be designed and customized to meet specific requirements, including different load-bearing capacities, heights, shapes, and finishes. This allows for flexibility in design and construction.

6. Low maintenance: Once installed, concrete floor support systems require minimal maintenance compared to other materials. Regular cleaning and occasional sealing are usually sufficient to keep the floor in good condition.

7. Cost-effectiveness: Concrete is a cost-effective material for floor support systems due to its long lifespan, low maintenance requirements, and availability. Additionally, its durability reduces the need for frequent repairs or replacements.

8. Sustainability: Concrete is an environmentally friendly material as it is made from abundant natural resources (such as limestone) and can be recycled or reused at the end of its life cycle. It also has a low embodied energy compared to other construction materials.

Overall, using a concrete floor support system offers numerous advantages in terms of strength, durability, fire resistance, sound insulation, thermal mass, versatility, low maintenance requirements, cost-effectiveness, and sustainability.