cost that is Low, minimal maintenance and durability make this the ideal flooring choice for manufacturing, commercial and other high traffic situations. With this particular technological innovation of concrete flooring, the floor will be kept warm even in the coldest climate and you are able to hike on the floor even without the need for shoe.

Here are Images about Concrete Floor Kit

Concrete Floor Kit

However, visual appeal as well as the performance of concrete could possibly be hampered by the practical protection aspects of its, especially for kids that are young . When included in basements, possessing bare concrete floors is a more hygienic choice from moldy carpets & rugs.

Rust-Oleum EpoxyShield 2-part Gray Gloss Garage Floor Epoxy Kit (2

There are several areas where the concrete polishing is actually being employed and many people tend to favor the polished concrete floor because of all the positive aspects which accrue to the owners of such floors. Consequently it is going to come as no surprise if you walk into a dwelling that has concrete floor polishing which there aren't any cracks, destroys or leaks on the outside.

Images Related to Concrete Floor Kit

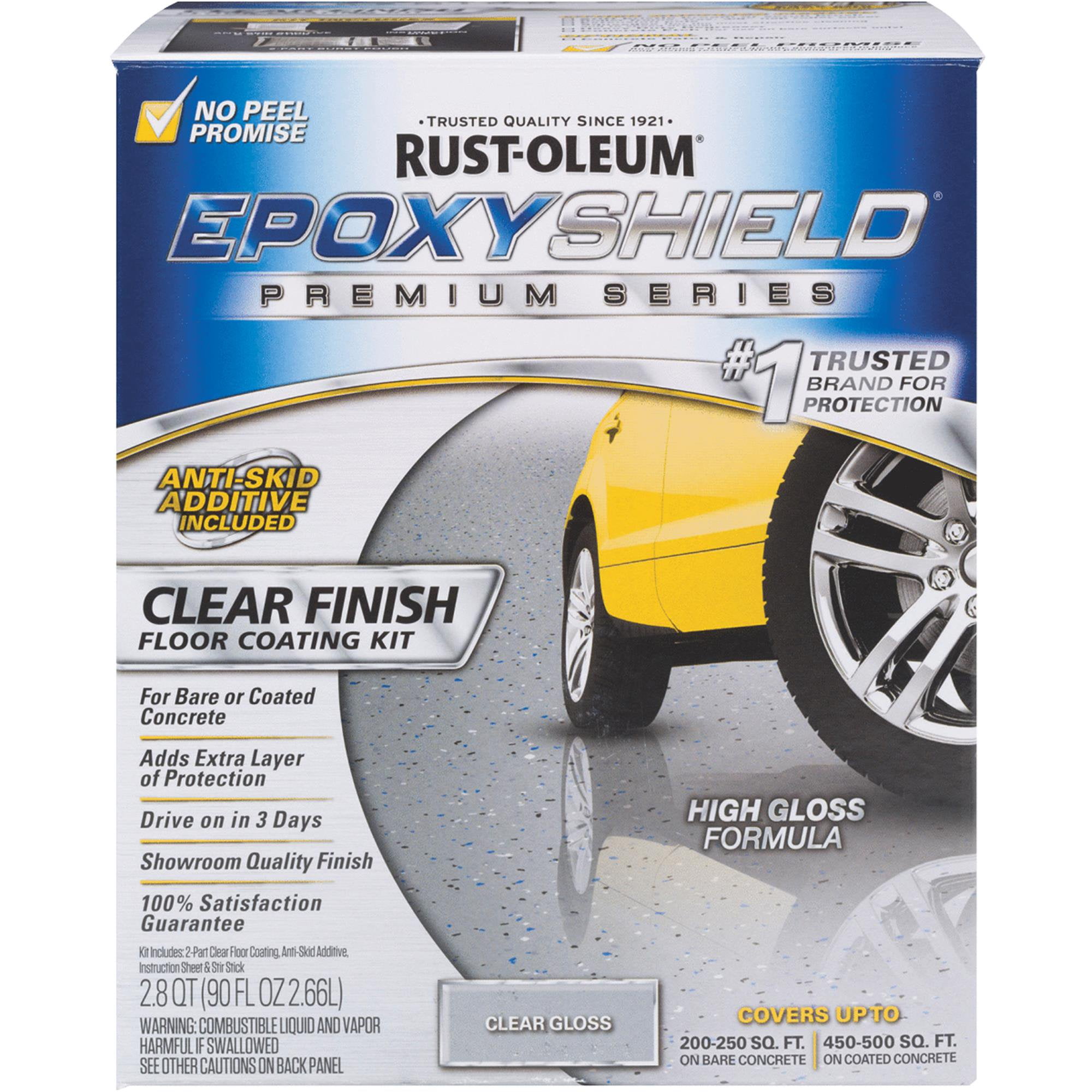

Floor Coating Kit,1 gal.,Epoxy,Clear RUST-OLEUM 292514

High Performance 100% Solids Industrial Floor Epoxy Kits

Param Polished Concrete Floor Kit

EPOXYShield Interior Concrete Floor Coatings

DAICH DaiHard Industrial Strength 3.7 Qt. Gray Gloss 100% Solids

E1016 Anti-Slip Epoxy Concrete Floor Coating – 3 Gal Kit

Do-It-Yourself Epoxy Floor Coating

Best Garage Floor Coating of 2022 – This Old House

/cdn.vox-cdn.com/uploads/chorus_image/image/68830856/1120_FEA_Idea_House_Fairfield_Farmhouse_08142020NR_0078_v3.0.jpg)

Metallic Mica Epoxy Concrete Garage Floor Countertop Paint Coating Pigment Kit z eBay

E1016 Anti-Slip Epoxy Concrete Floor Coating – 3 Gal Kit

Armor Chip Garage Epoxy Floor Coating ArmorGarage

Epoxy Floor Kit with Clear Top Coat – Epoxy-Coat Full Kit Black- up to 500 sq.ft. at 19.4 mils – for Garage Floors, Basement Floors, Concrete, and

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Title: The Ultimate Guide to Concrete Floor Kits: Transforming Your Space with Ease

Introduction:

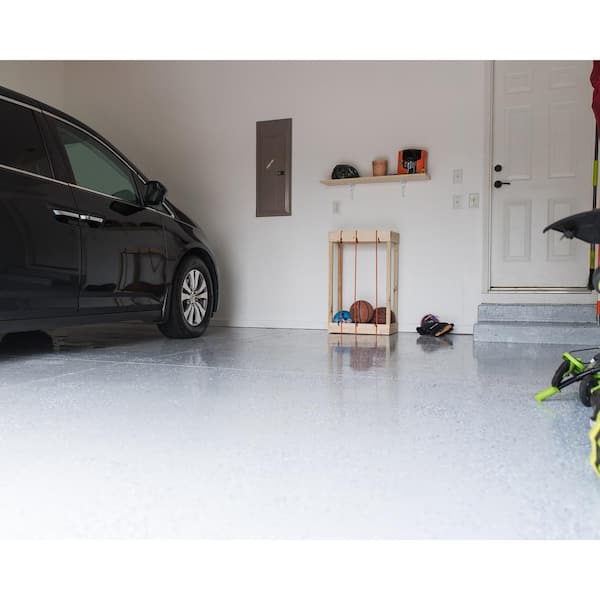

Concrete floors have become increasingly popular in recent years due to their durability, versatility, and modern aesthetic appeal. Whether you are looking to revamp your residential or commercial space, a concrete floor kit can provide a cost-effective solution that will stand the test of time. In this comprehensive guide, we will delve into the world of concrete floor kits, exploring their benefits, installation process, maintenance tips, and frequently asked questions.

I. Understanding Concrete Floor Kits:

Concrete floor kits are comprehensive packages that contain all the necessary materials and tools required to transform your existing flooring into a polished concrete masterpiece. These kits typically include epoxy or polyurethane coatings, sealants, cleaning solutions, and application tools.

FAQs:

1. What are the advantages of using a concrete floor kit?

Concrete floor kits offer numerous benefits, including enhanced durability, resistance to stains and chemicals, ease of maintenance, and limitless design options. Additionally, they can be applied to various surfaces such as wood, tile, or cement.

2. Can I install a concrete floor kit myself?

While some homeowners may opt for professional installation services for complex projects or large areas, many concrete floor kits are designed for DIY enthusiasts. Clear instructions and user-friendly tools make the installation process accessible to individuals with basic handyman skills.

II. Preparing for Installation:

Before diving into the installation process, it is crucial to adequately prepare your space for optimal results.

1. Surface Preparation:

Ensure that your existing flooring is clean and free from any debris or contaminants. Remove any loose paint or old adhesives using appropriate tools such as scrapers or grinders.

2. Repairing Damaged Areas:

Inspect your floor for cracks or imperfections that need repair before applying the concrete coating. Fill any holes or gaps with an epoxy filler and sand them down until smooth.

3. Moisture Testing:

Perform a moisture test to determine if your floor is suitable for a concrete coating. Elevated moisture levels can interfere with the curing process and compromise the durability of the finished product. Use a moisture meter or perform a simple plastic sheet test to assess the moisture content.

FAQs:

1. How long does it take to prepare the surface before applying the concrete coating?

The time required for surface preparation depends on the condition of your existing floor. Minor repairs and cleaning can be completed within a day, while extensive repairs or removal of old flooring may take longer.

2. Can I apply a concrete floor kit directly on top of carpet?

No, it is not recommended to apply a concrete floor kit directly over carpet. The carpet should be removed completely before starting the installation process.

III. Applying the Concrete Coating:

Once your surface is properly prepared, it’s time to apply the concrete coating and transform your space.

1. Priming:

Priming the surface ensures proper adhesion between the concrete coating and your existing floor. Apply a primer specifically designed for concrete coatings using a roller or sprayer, following the manufacturer’s instructions.

2. Applying the Concrete Coating:

Mix the epoxy or polyurethane coating components according to the instructions provided in your kit. Use a roller or squeegee to evenly apply the coating onto your floor, working in manageable sections. It is essential to maintain a consistent thickness throughout for an even finish.

3. Adding Color and Effects:

Concrete floor kits often come with options for customization, allowing you to add color pigments or decorative flakes to Create a unique look. Follow the instructions provided in your kit to apply these additional elements and achieve your desired aesthetic.

4. Curing and Drying:

After applying the concrete coating and any additional color or effects, allow the floor to cure and dry according to the manufacturer’s instructions. This usually involves leaving the floor untouched for a specified amount of time to ensure a durable and long-lasting finish.

FAQs:

1. Can I walk on the floor immediately after applying the concrete coating?

No, it is important to allow the floor to fully cure and dry before walking on it or placing any furniture or heavy objects on it. Follow the manufacturer’s instructions for curing times, as they may vary depending on the specific product used.

2. How long does it take for the concrete coating to fully cure?

The curing time can vary depending on factors such as temperature and humidity. It is recommended to wait at least 24 hours before allowing light foot traffic, and several days before subjecting the floor to heavier use.

IV. Maintenance and Care:

To ensure the longevity and appearance of your newly coated concrete floor, proper maintenance is essential.

1. Regular Cleaning:

Sweep or vacuum your floor regularly to remove dirt and debris that can cause scratches or damage over time. Use a mild cleanser and warm water for routine cleaning, avoiding harsh chemicals that may degrade the coating.

2. Avoiding Heavy Impact:

While concrete coatings are durable, they can still be susceptible to damage from heavy impacts or sharp objects. Take care when moving furniture or heavy items to avoid scratching or denting the surface.

3. Reapplying Protective Coating:

Over time, the protective coating may wear down and lose its luster. To maintain the appearance and protection of your floor, periodically reapply a fresh coat of concrete sealant or wax following the manufacturer’s instructions.

FAQs:

1. How often should I reapply a protective coating to my concrete floor?

The frequency of reapplication will depend on factors such as foot traffic and level of use. As a general guideline, it is recommended to reapply a protective coating every 1-3 years to keep your floor looking its best.

2. Can I use a pressure washer to clean my coated concrete floor?

It is generally not recommended to use a pressure washer on a coated concrete floor, as the high-pressure water can potentially damage or strip away the protective coating. Stick to gentle cleaning methods such as sweeping or mopping with mild cleansers.

3. Can I apply a new coat of concrete sealant or wax without removing the old one?

It is generally recommended to remove the old sealant or wax before applying a new coat. This ensures proper adhesion and prevents buildup or uneven application. However, always refer to the manufacturer’s instructions for specific guidance on reapplication.

4. How do I repair scratches or damage to my coated concrete floor?

Minor scratches can often be repaired by applying a touch-up coat of the original concrete coating or using a repair kit specifically designed for coated floors. For more severe damage, it may be necessary to consult a professional for repairs.

In conclusion, by allowing the concrete coating to fully cure, regularly cleaning and maintaining the floor, and periodically reapplying a protective coating, you can ensure a durable and long-lasting finish for your coated concrete floor.