Before installing some covering to the concrete floor of yours, it should be free and clean of any debris which might prevent bonding, including dirt, oil or sealer. The flooring is able to complement the room, creating a spectacular masterpiece. No trees are actually cut down when concrete is actually made, a lesser amount of power is actually produced to manufacture it as opposed to other flooring sorts, and concrete flooring doesn't have volatile organic compounds.

Here are Images about Concrete Floor Insulation Paint

Concrete Floor Insulation Paint

The spectacular increase in both science as well as technology have extra array of flooring options for the builders in addition to homeowners, and seems that concrete polish flooring is among the latest and hottest options among others. Concrete flooring nowadays has developed into a brand new flooring choice for homeowners and designers around the world.

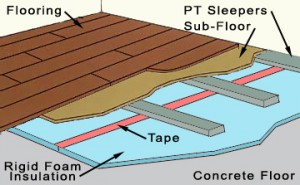

How to Insulate a Garage Floor With Plywood and Rigid Foam

/open-garage-with-concrete-driveway-1191772225-22b6b2d206fd4e08a86eb97d768efec7.jpg)

Today's concrete for flooring surfaces comes in a broad range of colors which are different, and it is doable to add in a variety of different stone and other elements to make a polished concrete floor a thing of attractiveness. Concrete flooring has appeal that is great for people excited about environmentally friendly construction.

Images Related to Concrete Floor Insulation Paint

Cool Coat White Thermal Barrier Heat Reflective Insulating Wall Paint Elastomeric

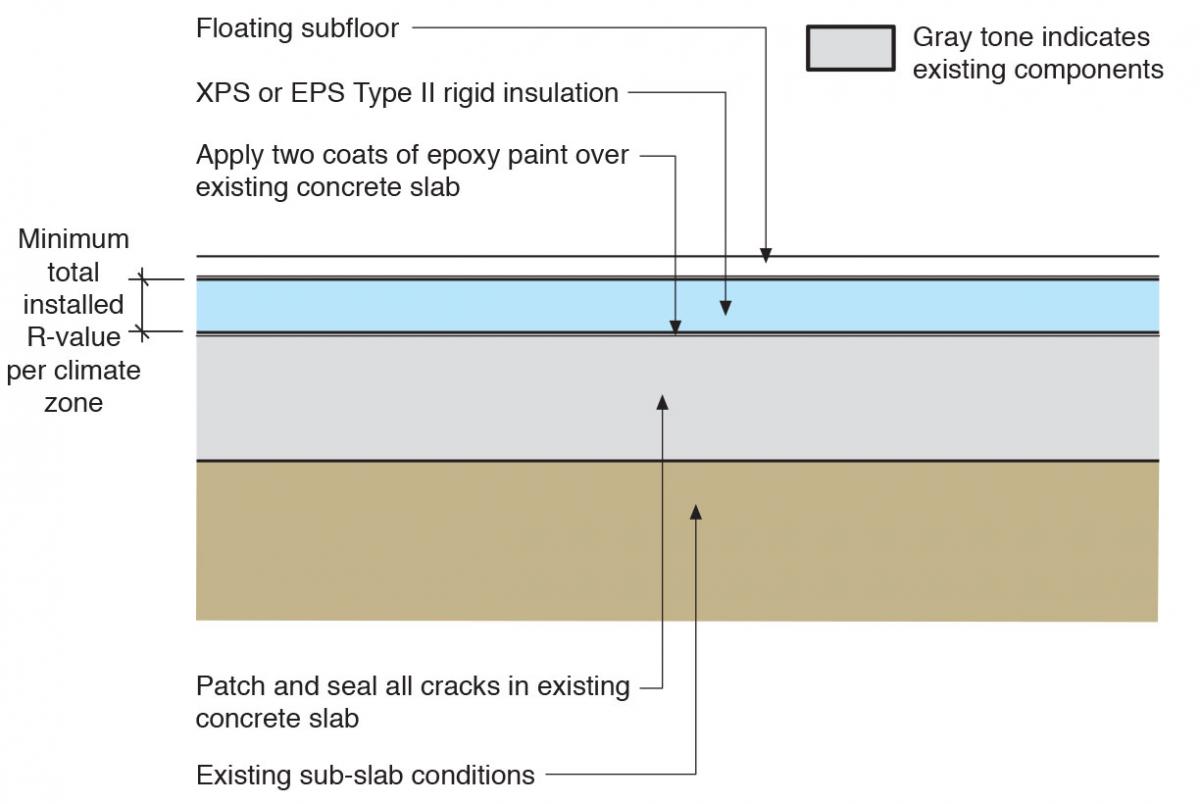

Rigid Foam Insulation Installed over Existing Foundation Slabs

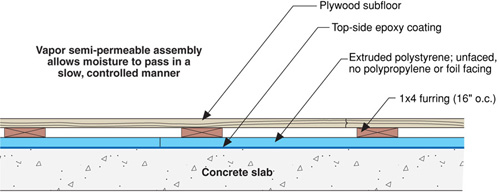

Installing Rigid Foam Above a Concrete Slab – GreenBuildingAdvisor

How to Prepare a Concrete Floor for Epoxy Paint

A Step-by-Step Guide to Using DuroSpan™ to Insulate your Basement

Basement Flooring – How To Insulate A Concrete Floor

Rigid Foam Insulation Installed over Existing Foundation Slabs

Heat Resistance Radiant Floor Insulation Concrete,Thermal Roll

How to Insulate a Garage Floor With Plywood and Rigid Foam

:max_bytes(150000):strip_icc()/Garage-Interior-200011513-001-56a49d5b5f9b58b7d0d7d8c7.jpg)

Basement Floor Paint Options HGTV

Easy Do-It-Yourself Epoxy Flooring Installation Guide We Are Extreme

How to Prepare a Concrete Floor for Epoxy Paint

Related articles:

- Concrete Floor Deck Construction

- Ugl Concrete Floor Paint

- Concrete Floor Leveling Grinding

- Concrete Floor Joist System

- Best Concrete Floor Leveler

- Concrete Floor With Wood Inlay

- How To Lay Porcelain Tiles On A Concrete Floor

- Faux Stained Concrete Floors

- 1 Part Epoxy Concrete Floor Paint

- How To Paint Or Stain Concrete Floors

Concrete Floor Insulation Paint: A Comprehensive Guide to Enhancing Comfort and Energy Efficiency

Introduction:

Concrete floors are widely used in residential, commercial, and industrial settings due to their durability and affordability. However, they can often feel cold and uncomfortable, especially during the winter months. Concrete floor insulation paint offers an innovative solution to this problem by providing a layer of insulation that enhances comfort and energy efficiency. In this article, we will explore the benefits of concrete floor insulation paint, its application process, frequently asked questions, and how it can transform your space into a cozy haven.

I. Understanding Concrete Floor Insulation Paint:

A. What is concrete floor insulation paint?

Concrete floor insulation paint is a specialized coating that is applied directly onto the surface of concrete floors. It contains insulating materials such as ceramic microspheres or expanded polystyrene beads that create a thermal barrier between the floor and the surrounding environment. This helps to regulate temperature fluctuations, reduce heat loss, and minimize cold spots in the room.

B. How does concrete floor insulation paint work?

The insulating properties of concrete floor insulation paint work on two main principles: reflective insulation and conductive insulation. Reflective insulation occurs when the paint reflects radiant heat back into the room instead of allowing it to escape through the floor. Conductive insulation involves slowing down the transfer of heat through the concrete by adding a layer of insulating material.

C. What are the benefits of using concrete floor insulation paint?

1. Enhanced comfort: By reducing heat loss through the floor, concrete floor insulation paint creates a warmer and more comfortable environment for occupants.

2. Energy efficiency: The added layer of insulation helps to prevent heat from escaping, which reduces reliance on heating systems and ultimately lowers energy consumption.

3. Noise reduction: Concrete floors can transmit sound vibrations easily, but with the application of insulation paint, noise transmission can be significantly reduced.

4. Moisture resistance: Some concrete floor insulation paints also offer moisture resistance, preventing water damage and mold growth.

5. Cost-effective: Compared to traditional floor insulation methods, such as installing underfloor heating systems or adding carpeting, concrete floor insulation paint is a more affordable option.

II. Applying Concrete Floor Insulation Paint:

A. Surface preparation:

1. Clean the floor thoroughly: Remove any dust, dirt, grease, or existing coatings from the surface of the concrete floor using a suitable cleaning solution.

2. Repair any cracks or imperfections: Fill in cracks or gaps in the floor using a concrete patching compound. Smooth out the patched areas for a level surface.

B. Choosing the right insulation paint:

1. Consider the R-value: The R-value measures the thermal resistance of an insulation material. Higher R-values indicate better insulating properties, so choose a paint with a higher R-value for more effective insulation.

2. Look for additional features: Some insulation paints offer additional benefits such as moisture resistance, anti-slip properties, or UV protection. Consider these features based on your specific requirements.

C. Application process:

1. Prime the surface: Apply a primer specifically designed for concrete floors to ensure proper adhesion of the insulation paint.

2. Mix and apply the paint: Follow the manufacturer’s instructions to mix the insulation paint thoroughly. Use a roller or brush to apply an even coat onto the prepared concrete floor surface.

3. Allow drying time: Depending on the product and environmental conditions, allow sufficient drying time before applying subsequent coats or allowing foot traffic on the painted surface.

4. Apply additional coats if necessary: Some insulation paints may require multiple coats for optimal performance. Follow the manufacturer’s instructions to determine if additional coats are needed.

5. Maintain and reapply as needed: Regularly maintain the insulation paint by cleaning the surface and reapplying as necessary to ensure continued effectiveness.

6. Enjoy the benefits: Once the insulation paint has dried and cured, enjoy the enhanced comfort, energy efficiency, noise reduction, and moisture resistance provided by the painted concrete floor. Concrete floor insulation paint offers several benefits, including enhanced comfort, energy efficiency, noise reduction, moisture resistance, and cost-effectiveness. To apply concrete floor insulation paint, the surface of the concrete floor must be prepared by cleaning it thoroughly and repairing any cracks or imperfections. When choosing an insulation paint, consider the R-value and any additional features that may be desired. The application process involves priming the surface and applying the paint in multiple coats as necessary. After allowing sufficient drying time, maintain and reapply the insulation paint as needed to enjoy its benefits. Concrete floor insulation paint offers several benefits, including enhanced comfort, energy efficiency, noise reduction, moisture resistance, and cost-effectiveness. To apply concrete floor insulation paint, the surface of the concrete floor must be prepared by cleaning it thoroughly and repairing any cracks or imperfections. When choosing an insulation paint, consider the R-value and any additional features that may be desired. The application process involves priming the surface and applying the paint in multiple coats as necessary. After allowing sufficient drying time, maintain and reapply the insulation paint as needed to enjoy its benefits.