Polished concrete flooring is a great way to conserve resources. Concrete floor takes a while to loosen up, but is incredibly efficient at holding that heat in, which means the house will stay warm on winter nights. Maintaining your concrete floor coating is very simple. Polished concrete floors are very simple to keep and manage.

Images about Cantilever Concrete Floor Slab

Cantilever Concrete Floor Slab

The primary reason is that these floors are energy efficient flooring options and definately will keep going for numerous years.

The most difficult thing is waiting: When the whole concrete floor is completed, you still must hold off parking the car on it for another seventy two hours.

There are concrete floors which seem plain and gray just like those found in factories and garages.

Structural Design of Cantilever Slabs – Solved Example – Structville

This kind of system works to stop long lasting degeneration of finished concrete floors.

No matter what could leak on it or be dragged across it, concrete flooring is virtually indestructible.

When you are thinking you wish to have a lot more alternatives than just a lustrous surface as well as color to work into the design ambitions of yours, then polished concrete is still the method to go.

Images Related to Cantilever Concrete Floor Slab

Add a Cantilever to a Structural Floor Revit Autodesk

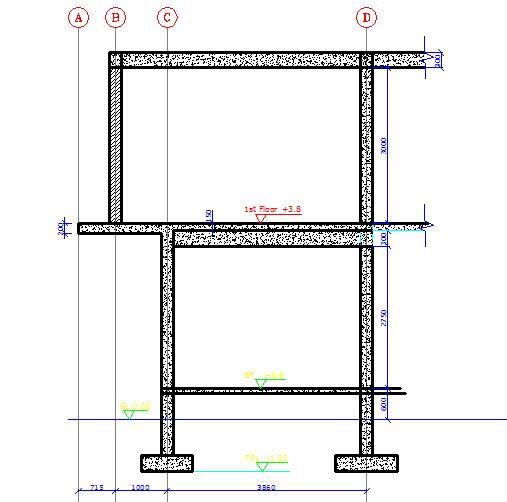

Elevation view of the cantilever portions. Download Scientific

Engineers React to Large Span Cantilever Slab Construction

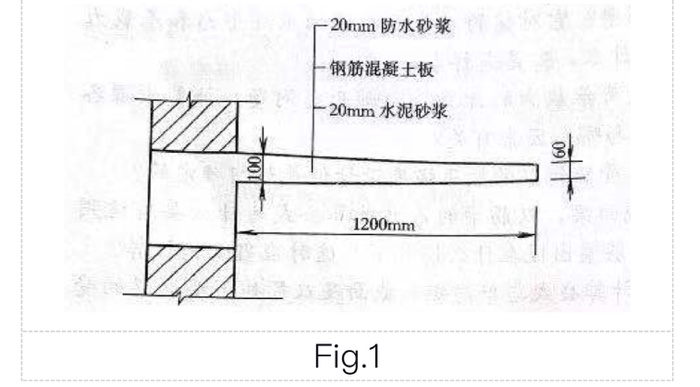

Cantilever Veranda Slab with Parapet Wall Detail Reinforced

Reinforced Concrete Constant Width Cantilever Slab Detail

Construction details. CYPE. EHU416: Transition to cantilevered

Cantilevered Concrete Slab Supporting Load Bearing Wall

Long cantilever in concrete slab by un bonded PT system by

Reinforced Concrete Constant Width Cantilever Slab Detail

Detail of strengthening of RC cantilever slabs Download

What is a cantilever slab? – Quora

Problem 3: Given a cantilever reinforced concrete Chegg.com

Related articles:

- Concrete Floor Resin Coating

- Concrete Floor Paint Preparation

- Stained Concrete Floor Designs

- How To Paint A Concrete Floor Inside

- Concrete Floor In Garage

- Polished Concrete Floor Ideas

- Gypsum Concrete Floor Underlayment

- Polishing Concrete Floor By Hand

- Concrete Floor Paint Prep

- Polished Concrete Floors For Patios

Creating a durable, long-lasting concrete floor slab is an essential element of any construction project. Cantilever concrete floor slabs provide a unique solution that can be used in a variety of applications. In this guide, we’ll explore the various advantages and disadvantages of cantilever concrete floor slabs, as well as the techniques for building and maintaining them.

What is a Cantilever Concrete Floor Slab?

A cantilever concrete floor slab is a type of slab that is designed to extend horizontally beyond its support. This type of slab is typically used when the structural load is too much for traditional methods to handle. It is also commonly used when access to the underside of the slab is not possible or feasible.

The main advantage of cantilever concrete floor slabs is that they can be constructed without having to use any formwork or shoring. This makes them ideal for projects where space is limited or there is limited access to the underside of the slab. Additionally, the horizontal forces generated by the cantilevered slab can be easily managed with reinforcing steel bars (rebars).

What are the Advantages and Disadvantages of Cantilever Concrete Floor Slabs?

The advantages of cantilever concrete floor slabs include:

– Cost savings – Since no formwork or shoring is required, these types of slabs are usually much less expensive than other types.

– Easy to install – Due to their simple design, these slabs are relatively easy to install compared to other types.

– Maximum flexibility – The horizontal forces created by cantilever slabs can be easily managed with rebar. This allows for maximum flexibility in terms of design and application.

The main disadvantage of cantilever concrete floor slabs is that they are not as strong as traditional slabs. This means that they are not suitable for heavy-duty applications such as warehouses or industrial buildings. Additionally, due to their lack of reinforcement, these types of slabs can be more prone to cracking and settlement than other types.

How Do I Build a Cantilever Concrete Floor Slab?

Building a cantilever concrete floor slab involves several steps:

– Preparation – Begin by excavating the area where you plan to build the slab and preparing the subgrade for proper drainage. Additionally, you will need to make sure that the edges of the slab are properly prepared with reinforced steel bars (rebar).

– Pouring – Once the subgrade has been prepared, you will need to pour and level the concrete for the slab. Be sure to use a vibrator to ensure that there are no air bubbles in the concrete mix.

– Curing – After pouring the concrete, you will need to allow it to cure for at least 24 hours before beginning any construction on top of it. During this time, it is important that you keep it wet with water in order to prevent cracking and settlement.

– Finishing – Once your cantilever concrete floor slab has finished curing, you will need to finish it with a sealer or other protective coating in order to prevent staining or damage from weathering.

How Do I Maintain a Cantilever Concrete Floor Slab?

Maintaining a cantilever concrete floor slab requires regular inspection and cleaning:

– Inspection – Inspect your cantilever concrete floor slab regularly for signs of cracking or settlement. If you notice any issues, address them immediately in order to prevent further damage.

– Cleaning – Regularly clean your cantilever concrete floor slab in order to keep it looking its best and reduce potential staining or wear from weathering. Use mild detergents and water, avoiding any harsh chemicals or abrasive scrubbing pads which could cause damage.

– Sealing – Apply sealant every few years in order to protect against staining and wear from weathering. Make sure you use a product specifically designed for concrete surfaces in order to ensure that it lasts as long as possible.

Conclusion

Cantilever concrete floor sl