Today's concrete for floor surfaces comes in a wide variety of styles, and it's feasible to include in an assortment of other elements and different stone to produce a polished concrete floor a thing of attractiveness. Concrete flooring has appeal which is great for all keen on green construction.

Here are Images about Concrete Floor Joint Sealant

Concrete Floor Joint Sealant

to be able to modify the color of the floor, buyers might request shake-on color hardeners or penetrating synthetic stains as well as dyes to change their grey colored concrete to any kind of range of styles. Lately that has changed as more and more individuals are realizing that a polished concrete floor actually looks great. Polished concrete flooring looks far more slippery than it is.

Fast-Setting Flexible Expansion Joint Filler with No VOCs

The labor involved in fitting a concrete floor could be very high, even thought the price of the items is lower than for all kinds of other types of flooring. This's due to the sleek looks and influences which may be created, but also within part to the many advantages that polished concrete has over other flooring options.

Images Related to Concrete Floor Joint Sealant

Joint Sealants

Floor Joint Reseal Repair – CG Flooring Systems

Elastomeric sealant – FLOOR JOINT – Watco Industrial Flooring

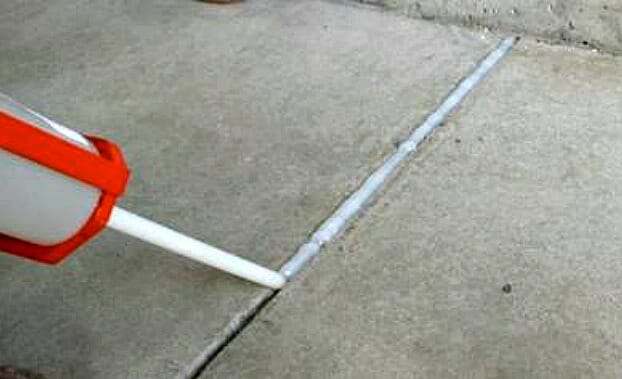

Application sealing floor joints

ARMORPOXY FLEXIBLE JOINT SEALANT

Houston Texas Concrete Driveway Repair: Pool Coping u0026 Sealing

How to Caulk Concrete Control Joints with Perfect Results Every Time

Joint Sealants

How to Fill Expansion and Contraction Joints in a Garage Floor

Concrete Expansion Joints u2013 Home Repair Tutor

Floor Joint Arris Repair – CG Flooring Systems

Epoxy vs. Polyurea Joint Fillers: Which is best? – Concrete Decor

Related articles:

- How To Seal Concrete Floor In Garage

- Concrete Floor Thickness Industrial

- Acid Stain Basement Concrete Floor

- Concrete Floor Hole Repair

- How To Seal Concrete Floor Before Painting

- Concrete Floor Epoxy Filler

- Wood Flooring Over Concrete Floor

- Pex Concrete Floor Heating

- Acid Stain Concrete Floors Yourself

- Stained Concrete Floor Color Charts

Concrete Floor Joint Sealant: A Comprehensive Guide

Introduction:

Concrete floors are widely used in industrial and commercial spaces due to their durability and strength. However, without proper maintenance, these floors can develop cracks and joints over time. To prevent further damage and ensure the longevity of the floor, applying a concrete floor joint sealant is essential. In this comprehensive guide, we will delve into the details of concrete floor joint sealants, their types, application methods, benefits, and frequently asked questions.

I. Understanding Concrete Floor Joints:

Concrete floor joints are intentional gaps left between two adjacent sections of concrete to allow for expansion and contraction caused by temperature variations or other factors. These joints also help to distribute loads evenly across the floor surface and minimize the risk of cracking. While these joints serve an important purpose, they can become areas of concern if not properly sealed.

1. Why do concrete floor joints need to be sealed?

Concrete floor joints are vulnerable to moisture penetration, dust accumulation, chemical spills, and debris buildup. If left unsealed, these issues can lead to structural damage, safety hazards, and aesthetic deterioration. Sealing the joints with a concrete floor joint sealant provides protection against these potential problems.

2. When should concrete floor joints be sealed?

Ideally, concrete floor joints should be sealed as soon as they are formed or after any necessary repairs have been carried out. Prompt sealing minimizes the exposure of the joints to external elements and prevents further damage.

II. Types of Concrete Floor Joint Sealants:

Various types of sealants are available in the market for sealing concrete floor joints. Choosing the right type depends on factors such as joint width, expected movement, chemical exposure, aesthetics, and budget.

1. Silicone-based Sealants:

Silicone-based sealants offer excellent flexibility and adhesion properties. They are suitable for both interior and exterior applications due to their resistance to UV radiation and extreme temperatures.

FAQ: Are silicone-based sealants suitable for high-traffic areas?

Yes, silicone-based sealants are highly durable and can withstand heavy foot traffic. They are often used in industrial and commercial settings where the floor is subjected to constant use.

2. Polyurethane-based Sealants:

Polyurethane-based sealants are known for their exceptional durability and resistance to chemicals, abrasion, and weathering. They provide excellent adhesion to concrete surfaces and can accommodate a wide range of joint movements.

FAQ: Can polyurethane-based sealants be applied on wet surfaces?

Some polyurethane-based sealants are formulated to be moisture-cured, allowing them to be applied on damp or wet surfaces. However, it is important to follow the manufacturer’s instructions for proper application.

3. Epoxy-based Sealants:

Epoxy-based sealants are highly resistant to chemicals, making them suitable for areas exposed to harsh substances such as laboratories or manufacturing facilities. They provide a smooth and seamless finish while offering excellent adhesion and durability.

FAQ: Can epoxy-based sealants be used in outdoor applications?

While epoxy-based sealants are primarily designed for indoor use, there are certain formulations available that can withstand outdoor conditions. It is crucial to choose the right type of epoxy sealant based on the specific application requirements.

III. Application Methods:

Applying concrete floor joint sealant requires careful preparation and precise execution to ensure optimal results. There are several methods commonly used for sealing concrete floor joints:

1. Routing and Sealing:

This method involves cutting a groove along the joint using specialized equipment Such as a router or saw. The groove is then filled with the sealant to create a tight and secure seal. Routing and sealing is commonly used for larger joints or where high movement is expected.

2. Backer Rod and Sealant:

Backer rod, a flexible foam material, is inserted into the joint to provide support and create a proper sealant depth. The joint is then filled with the sealant, ensuring it adheres to the backer rod. This method is effective for smaller joints or where minimal movement is anticipated.

3. Pouring and Tooling:

With this method, the sealant is poured directly into the joint and then tooled to ensure proper adhesion and a smooth finish. It is typically used for narrow joints or where aesthetics are important.

It is important to follow the manufacturer’s instructions for each specific sealant product and application method to achieve the best results. Additionally, regular inspection and maintenance of sealed joints are necessary to identify any signs of damage or deterioration and address them promptly. Sealed joints play a crucial role in maintaining the integrity and longevity of concrete floors. Whether it’s for residential, commercial, or industrial applications, choosing the right sealant and applying it correctly is essential for ensuring optimal performance.

I. Types of Concrete Floor Sealants:

1. Silicone-based Sealants:

Silicone-based sealants offer excellent flexibility and are ideal for joints that experience a high degree of movement. They are resistant to UV radiation and extreme temperatures, making them suitable for both indoor and outdoor applications. Silicone sealants also provide good adhesion to a wide range of materials.

2. Polyurethane-based Sealants:

Polyurethane-based sealants are known for their exceptional durability and resistance to chemicals, abrasion, and weathering. They provide excellent adhesion to concrete surfaces and can accommodate a wide range of joint movements.

FAQ: Can polyurethane-based sealants be applied on wet surfaces?

Some polyurethane-based sealants are formulated to be moisture-cured, allowing them to be applied on damp or wet surfaces. However, it is important to follow the manufacturer’s instructions for proper application.

3. Epoxy-based Sealants:

Epoxy-based sealants are highly resistant to chemicals, making them suitable for areas exposed to harsh substances such as laboratories or manufacturing facilities. They provide a smooth and seamless finish while offering excellent adhesion and durability.

FAQ: Can epoxy-based sealants be used in outdoor applications?

While epoxy-based sealants are primarily designed for indoor use, there are certain formulations available that can withstand outdoor conditions. It is crucial to choose the right type of epoxy sealant based on the specific application requirements.

III. Application Methods:

Applying concrete floor joint sealant requires careful preparation and precise execution to ensure optimal results. There are several methods commonly used for sealing concrete floor joints:

1. Routing and Sealing:

This method involves cutting a groove along the joint using specialized equipment such as a router or saw. The groove is then filled with the sealant to create a tight and secure seal. Routing and sealing is commonly used for larger joints or where high movement is expected.

2. Backer Rod and Sealant:

Backer rod, a flexible foam material, is inserted into the joint to provide support and create a proper sealant depth. The joint is then filled with the sealant, ensuring it adheres to the backer rod. This method is effective for smaller joints or where minimal movement is anticipated.

3. Pouring and Tooling:

With this method, the sealant is poured directly into the joint and then tooled to ensure proper adhesion and a smooth finish. It is typically used for narrow joints or where aesthetics are important.

It is important to follow the manufacturer’s instructions for each specific sealant product and application method to achieve the best results. Additionally, regular inspection and maintenance of sealed joints are necessary to identify any signs of damage or deterioration and address them promptly.