The latest developments in the ability to seal and stain concrete have raised its aesthetic appeal, allowing it to compete with some other stone flooring like marble, slate and granite – at a fraction of the price. Be a sensible man or women and embrace concrete as floors that's not just safe for you but additionally to the environment.

Here are Images about Reinforced Concrete Floor Slab Design

Reinforced Concrete Floor Slab Design

Working with polished concrete floors is something which most people is not always perfectly clued all about. Do you've polished concrete floors, or maybe terrazzo floors? This makes knowing what type of paint to go with a lot easier. Dust, dander and dust mites can all be stopped by using this kind of flooring.

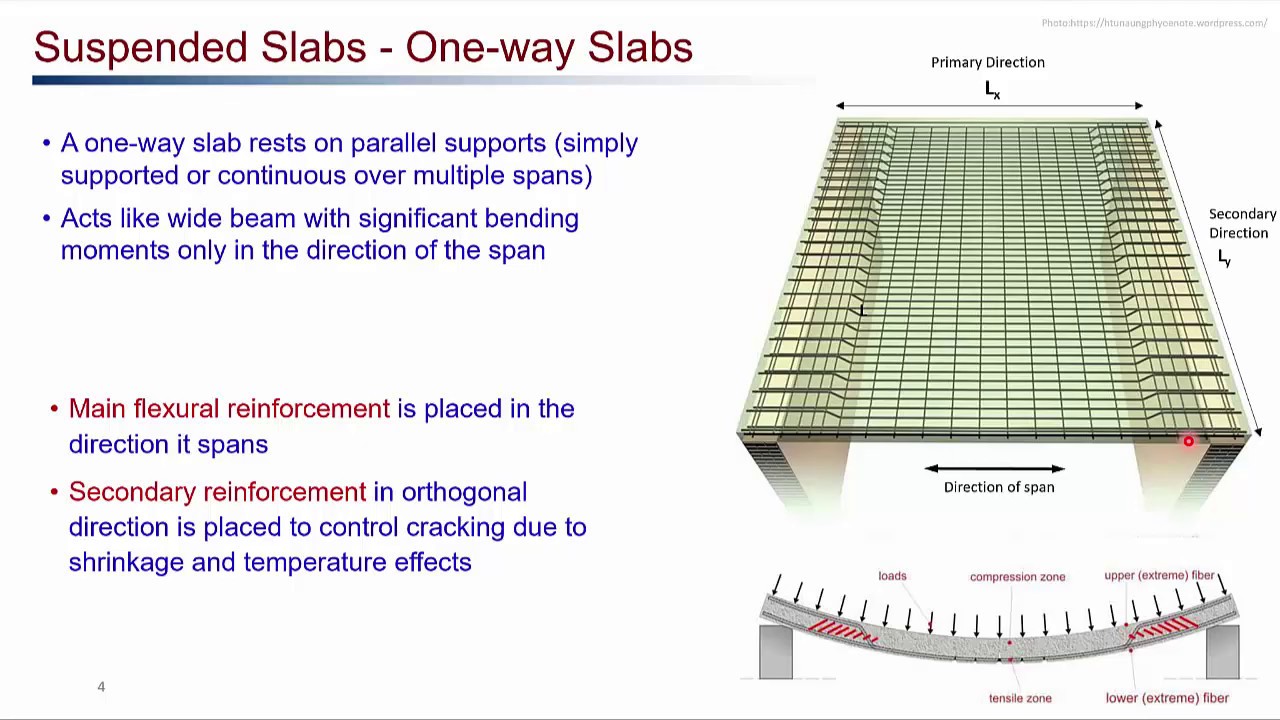

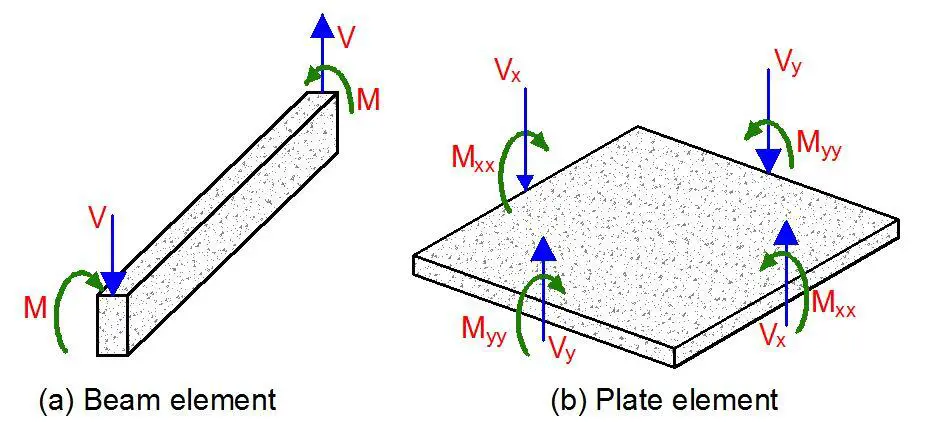

How to Design One-way Slab as per ACI 318-19? Example Included

If needed, consider re-applying the sealant as this will go quite a distance to boosting the life expectancy as well as appearance of the concrete floors. The initial step before considering some tips and tricks is figuring out what sort of concrete you've. The hottest technology to make the boring of yours and lifeless concrete flooring into a shiny and polished mirror.

Images Related to Reinforced Concrete Floor Slab Design

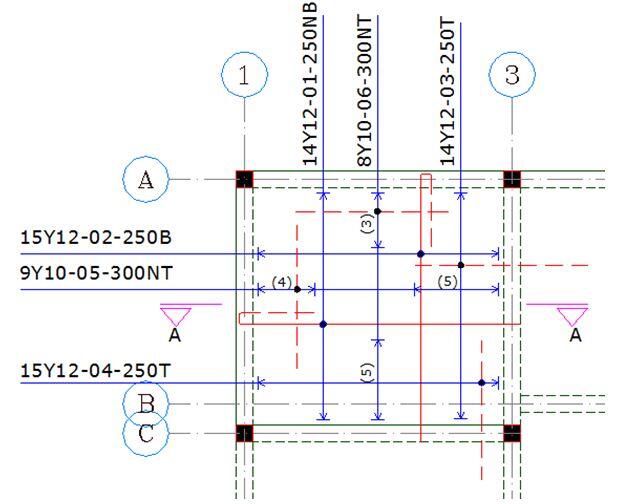

Working with Design of a Reinforcement Concrete Slab

Causes of Excessive Deflections in Reinforced Concrete Slabs

Notes Engineering: REINFORCED CONCRETE SLAB DESIGN

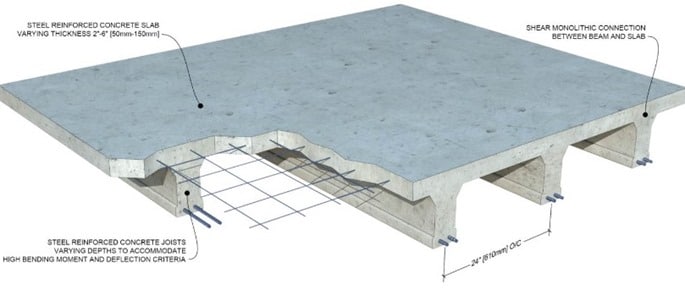

Floor Slab – an overview ScienceDirect Topics

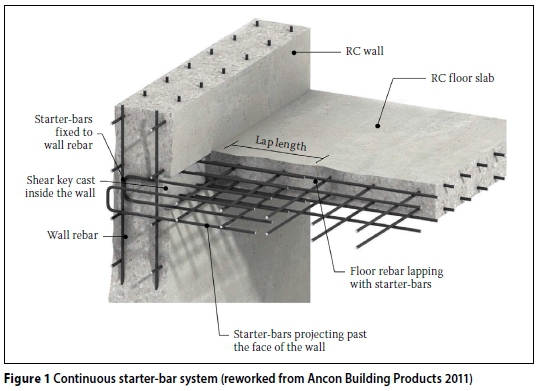

Alternative wall-to-slab connection systems in reinforced concrete

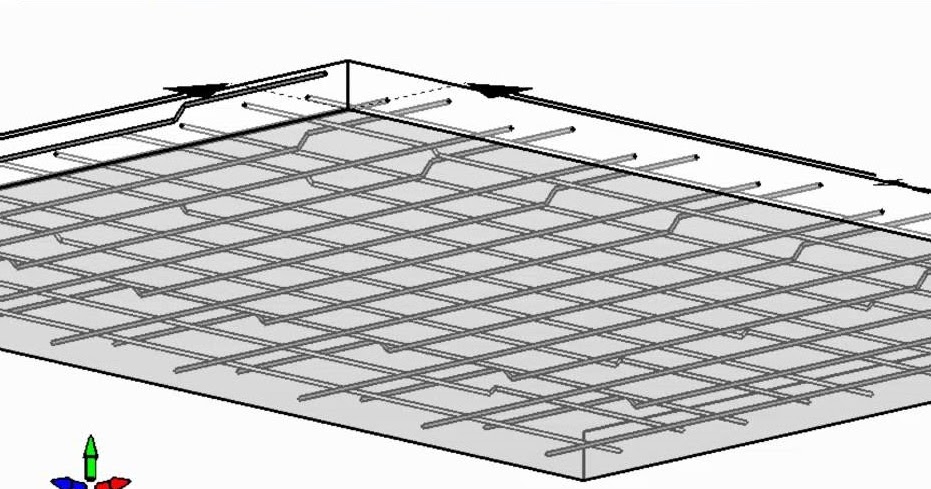

Reinforced concrete slab Reinforced concrete floor GUIDE

Design of Reinforced Concrete (R.C.) Slabs – Structville

RCD:- One way slab design / design of a one way RC slab.

Design of Reinforced Concrete (R.C.) Slabs – Structville

Reinforced Concrete Constant Width Cantilever Slab Detail

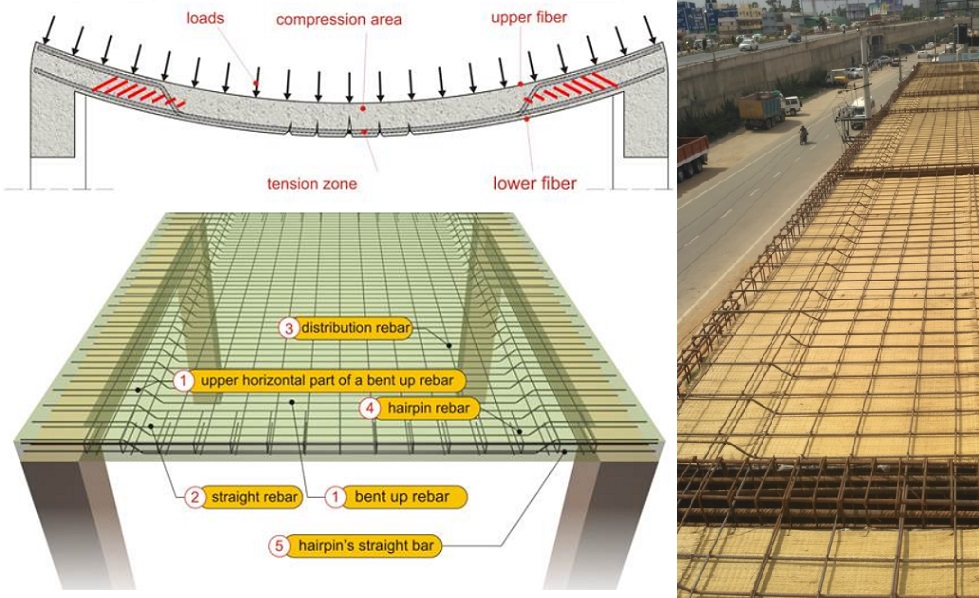

Reinforcement of cast-in-place reinforced concrete slab

Design of Reinforced Concrete (R.C.) Slabs – Structville

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Reinforced concrete floor slabs are an integral part of many building structures. They are strong, durable, and provide a solid foundation for other structural elements. Designing reinforced concrete floor slabs requires careful consideration of several factors such as load requirements, span, and slab thickness. This article will provide an overview of the design process for reinforced concrete floor slabs, including common questions and answers related to the topic.

Load Requirements

The first step in the design process is to consider the loads that will be placed on the floor slab. It is important to consider both dead and live loads when designing a reinforced concrete floor slab. Dead loads refer to the weight of permanent fixtures such as walls, pipes, and furniture. Live loads refer to temporary loads such as people, furniture, or equipment. The designer must determine the total load on the floor and use this information to determine the size and type of reinforcement needed to support it.

Span

The span of the floor slab is another important factor when designing a reinforced concrete floor slab. This refers to the distance between two supports for the slab. The span length will affect the thickness of the slab as well as the amount and type of reinforcement needed. The longer the span, the thicker and more heavily reinforced the slab will need to be in order to safely support the load.

Slab Thickness

Once the load requirements and span have been determined, the designer can determine an appropriate slab thickness. There are several factors that influence this decision including structural requirements, type of finish desired, and cost factors. Generally speaking, thinner slabs will increase cost but can reduce construction time while thicker slabs may require more time and resources but can provide greater support strength.

Common Questions about Reinforced Concrete Floor Slab Design

Q: What type of reinforcement should be used in a reinforced concrete floor slab?

A: The type of reinforcement used in a reinforced concrete floor slab will depend on several factors such as load requirements, span length, and slab thickness. Generally speaking, steel mesh or rebar is most commonly used for reinforcement in a reinforced concrete floor slab.

Q: What is the minimum thickness for a reinforced concrete floor slab?

A: The minimum thickness for a reinforced concrete floor slab will depend on several factors such as load requirements and span length. Generally speaking, a minimum thickness of 4 inches (10 cm) is recommended for residential applications with lighter loads while larger applications may require thicker slabs up to 8 inches (20 cm).

Q: What other considerations should be taken into account when designing a reinforced concrete floor slab?

A: In addition to load requirements, span length, and slab thickness, other considerations should also be taken into account when designing a reinforced concrete floor slab. These include environmental conditions that may affect the integrity of the slab such as moisture content or extreme temperatures. Additionally, it is important to consider any additional finishes that may need to be applied such as paint or tile.

Conclusion

Designing a reinforced concrete floor slab requires careful consideration of several factors including load requirements, span length, and slab thickness. By understanding these key elements and carefully assessing each factor, designers can create effective and structurally sound reinforced concrete floor slabs that will last for years to come.