Epoxy coatings are going to react with earlier installed coatings. By simply adding a work bench as well as a little epoxy flooring covering you have a professional looking project and a floor that could be enjoyed for years to come. You will probably be thinking off including a store or transforming your garage into a work shop. The greatest thing about epoxy is that it makes an attractive yet very simple look.

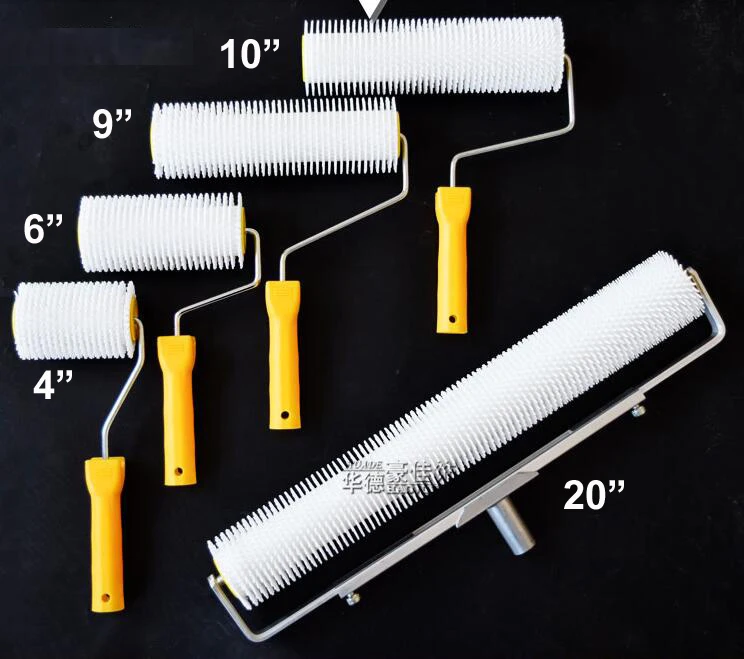

Here are Images about Tools For Epoxy Flooring

Tools For Epoxy Flooring

Epoxy coat is also of low porosity and is chemical resistant. The surface is really simple to keep and it is strong to sustain abusive use by commercial or heavy-traffic scale operations. You will quickly realize that epoxy flooring is very convenient as it meets almost all of the industrial requirements. These elements assault industrial floors often in the course of everyday operations.

Single Installation Tool Kit

Making slip-resistant floors is actually possible by employing appropriate additives to the epoxy compound mix. Part of the interest designers have within epoxy flooring would be that once totally dried out, the floor will provide a superior, glossy shine. You do not need to replace your floors; you can effortlessly enhance the concrete of yours, etc with some epoxy. This epoxy resin is clear, and can develop a shiny but non-slip surface.

Images Related to Tools For Epoxy Flooring

Floor Coating u0026 Painter Application Tools Rollers Paint Brushes

How to Apply Garage Floor Epoxy Coatings The DIY Guide All

Steel Needle Bubble Elimination Roller Cement self-leveling Epoxy floor Tool Y eBay

Maydos Epoxy Flooring Tools(trowel/roller/mixer/grinder) – Buy

Epoxy Flooring AppEpoxy Rollers, Brushes u0026 Equipment licator Pack

560mm Self-Leveling Scraper Epoxy Floor Coating Tools – China Self

Epoxy Flooring Supplies u0026 Materials List Thermal-Chem

spike roller epoxy roller flooring tools remove bubbles Tooth

Industrial Flooring Concrete Coatings Best Epoxy – Concrete Tools

Cement Self-leveling Kit Epoxy Floor Paint Roller Blade Spike

1.5-Gallon Epoxy – Tools Included

Details about Construction Tool Self-leveling Cement Kit Epoxy Floor Paint+Roller Blade Tools

Related articles:

- DIY Epoxy Floor Garage

- Epoxy Flooring Systems Grand Forks

- Epoxy Flooring Nashville Tn

- Metallic Epoxy Flooring In Bangalore

- Affordable Epoxy Flooring Installers

- Epoxy Floor Paint Quality

- Epoxy Floor Paint Philippines

- Epoxy Flooring Windsor Ontario

- Epoxy Flooring Rockford Il

- Epoxy Floor Nj

Epoxy flooring is a popular choice for many homeowners and businesses due to its durability, aesthetic appeal, and ease of maintenance. However, in order to achieve a successful epoxy flooring installation, it is crucial to have the right tools on hand. From preparation to application, having the proper tools can make all the difference in the outcome of your epoxy flooring project.

Surface Preparation Tools:

Before applying epoxy flooring, it is essential to properly prepare the surface to ensure adhesion and longevity. Some common surface preparation tools include:

1. Floor Grinder: A floor grinder is used to remove any existing coatings or adhesives from the floor, as well as to roughen up the surface for better adhesion of the epoxy coating.

2. Shot Blaster: A shot blaster is another tool that can be used to prepare the surface by blasting it with small steel shot to create a rough texture and remove contaminants.

3. Concrete Etcher: A concrete etcher is used to open up the pores of the concrete surface, allowing for better penetration of the epoxy coating.

FAQs:

Q: Can I skip surface preparation when installing epoxy flooring?

A: No, proper surface preparation is crucial for a successful epoxy flooring installation. Skipping this step can result in poor adhesion and premature coating failure.

Epoxy Flooring Application Tools:

Once the surface has been properly prepared, it’s time to apply the epoxy coating. Some essential tools for epoxy flooring application include:

1. Squeegee: A squeegee is used to spread the epoxy coating evenly over the surface, ensuring a smooth finish.

2. Roller: A roller can be used to backroll the epoxy coating after it has been applied with a squeegee, helping to eliminate air bubbles and achieve an even coat.

3. Spike Shoes: Spike shoes are worn during the application process to prevent footprints in the wet epoxy coating.

4. Mixing Paddles: Mixing paddles are used to mix the epoxy resin and hardener together before application.

FAQs:

Q: Do I need special shoes for applying epoxy flooring?

A: Spike shoes are recommended for applying epoxy flooring to prevent footprints in the wet coating and ensure a smooth finish.

Finishing Tools:

After applying the epoxy coating, there are a few finishing touches that can be made using specialized tools:

1. Edger Tool: An edger tool is used to cut in along edges and corners where a roller cannot reach, ensuring complete coverage of the epoxy coating.

2. Non-Slip Additives: Non-slip additives can be mixed into the final coat of epoxy flooring to provide added traction and safety.

3. Sealant: A sealant can be applied over the finished epoxy flooring to protect against scratches, stains, and UV damage.

FAQs:

Q: Do I need a sealant for my epoxy flooring?

A: While not necessary, applying a sealant over your finished epoxy flooring can provide added protection against wear and tear.

Maintaining Epoxy Flooring Tools:

Once your epoxy flooring has been installed, it’s important to have the right tools on hand for maintenance and upkeep:

1. Microfiber Mop: A microfiber mop can be used for regular cleaning of your epoxy flooring without damaging the finish.

2. Neutral pH Cleaner: A neutral pH cleaner should be used when mopping your epoxy flooring to avoid damaging the finish.

3. Soft Bristle Broom: A soft bristle broom can be used to sweep debris off The epoxy flooring without scratching or damaging the surface.

4. Floor Mats: Placing floor mats at entryways can help prevent dirt, debris, and moisture from being tracked onto the epoxy flooring, prolonging its lifespan.

5. Soft Cloth: A soft cloth can be used to wipe up spills or stains on the epoxy flooring to prevent damage.

FAQs:

Q: How often should I clean my epoxy flooring?

A: Epoxy flooring should be cleaned regularly with a microfiber mop and neutral pH cleaner to maintain its appearance and prolong its lifespan.

In conclusion, having the right tools for every step of the epoxy flooring installation process is crucial for achieving a successful and long-lasting finish. From surface preparation to application and maintenance, using the proper tools will ensure that your epoxy flooring looks great and performs well for years to come. If you have any additional questions about epoxy flooring or the tools needed for installation and maintenance, feel free to reach out to a professional for guidance. Happy flooring! Overall, it is essential to have the right tools for every stage of the epoxy flooring installation process. From surface preparation to application and maintenance, using the proper tools will ensure a successful and long-lasting finish. If you have any questions about epoxy flooring or the tools needed for installation and upkeep, don’t hesitate to seek guidance from a professional. With the right tools and techniques, your epoxy flooring can look great and perform well for years to come. Happy flooring!