Ceramic tile can look Southwestern, starkly contemporary or perhaps easily traditional. When you used to think of floor tile flooring, you might have believed white, off truly white, or black colored as that was essentially what was available. Whatever technique you choose to learn from, take copious notes in order to do a fantastic job on ones own. In terms of maintenance, tile flooring is actually one of the easiest to handle.

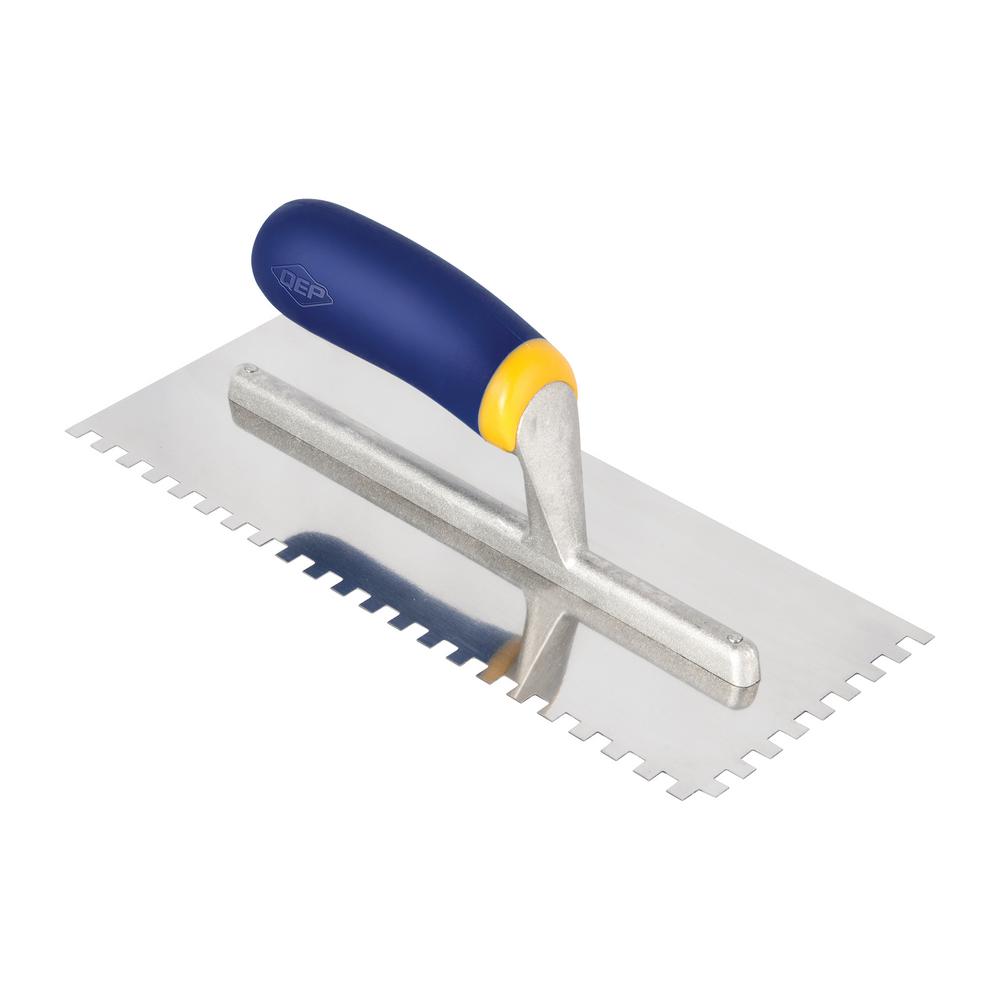

Images Related to Tile Floor Tools

Tile Floor Tools

Tiled floors inside kitchens, joints and food processing facilities typically include very high concentrations of germ and bacteria buildup. Since they are thicker than typical tiles and in a position to resist traffic that is heavy, they might be much less susceptible to cracking compared to a vulnerable, thinner tile. They are able to provide the effect of having drinking water on the floors of yours that's oh so dramatic.

10 Must Have Tile Installation Tools for Professional Installers

Lots of professional installers are able to get you floor tile at an excellent discount, particularly when they're installing the tile floor. Many of the choices are stock items therefore you will not have to wait for a particular order to come in. You can use a tile cutter or perhaps a glasscutter for small jobs, but for larger assignments you may possibly need to have a damp saw.

10 Tiling Tools to Help With Your Next Tile Project

:max_bytes(150000):strip_icc()/tools-for-any-tile-job-1822758-01-2eede57079034d348e970fab975987aa.jpg)

Top 5 Best Tile Tools for Perfect Tiles Installation

28 Different Types of Tiling Tools – Home Stratosphere

Ceramic Tiles And Tools For Tiler Floor Tiles Installation Home

All Tools Needed for Installing Tile Flooring – Home Stratosphere

Flooring Tools – Flooring Supplies – The Home Depot

10 Tiling Tools to Help With Your Next Tile Project

/tools-for-any-tile-job-1822758-hero-5ee3928f4ce44682a83d4c610d56015c.jpg)

10 Must Have Tile Installation Tools for Professional Installers

Ceramic Tiles And Tools For Tiler Floor Tiles Installation Home

Tiling Tools Large Tile Installation Madison WI

Ceramic Tiles And Tools For Tiler Floor Tiles Installation Home

Ceramic tiles and tools for tiler. Worker hand installing floor

Related articles:

- White Bathroom Ceramic Tiles

- Bathroom Floor Baseboard

- Rustic Bathroom Flooring Ideas

- Bathroom Flooring Options

- Bamboo Bathroom Flooring Ideas

- Small Bathroom Floor Tile Patterns Ideas

- Choosing Bathroom Floor Tile

- Dark Wood Bathroom Floor

- Bathroom Flooring Choices

- Mosaic Bathroom Floor Tile Design

Tile Floor Tools: A Comprehensive Guide to the Essential Equipment for Your Flooring Projects

Introduction:

When it comes to tile flooring projects, having the right tools at your disposal can make all the difference. From precision cutting to efficient installation, using the appropriate tile floor tools ensures a professional finish and saves you valuable time and effort. In this comprehensive guide, we will explore the essential tools needed for any tile flooring project, along with detailed explanations of their functions, tips for usage, and answers to frequently asked questions.

1. Tile Cutters:

Tile cutters are indispensable tools for achieving clean and precise cuts on ceramic or porcelain tiles. The two main types of tile cutters are manual and electric.

a) Manual Tile Cutters:

Manual tile cutters consist of a base, scoring wheel, and breaking mechanism. They offer excellent control and accuracy when cutting straight lines. To use a manual tile cutter, follow these steps:

– Measure and mark the desired cutting line on the tile.

– Place the tile on the base of the cutter, aligning the marked line with the scoring wheel.

– Apply pressure on both ends of the tile to score it with the wheel.

– Activate the breaking mechanism by pushing down on the handle or using a separate breaker bar.

– The tile should break cleanly along the scored line.

FAQs:

Q1: Can I use a manual tile cutter for irregular or curved cuts?

A1: Manual tile cutters are primarily designed for straight cuts. For irregular or curved cuts, it is recommended to use other tools such as wet saws or nippers.

Q2: What is the advantage of using a manual tile cutter over an electric one?

A2: Manual tile cutters are portable, lightweight, and do not require electricity. They are suitable for smaller projects or when working in areas without power sources.

b) Electric Tile Cutters:

Electric tile cutters are powered machines that facilitate faster and more efficient cutting of tiles. They are particularly useful for larger projects or when dealing with thicker tiles.

– Wet Tile Saws:

Wet tile saws are electrically powered machines equipped with a diamond blade that cuts through tiles with water-cooling. The water minimizes dust and keeps the blade cool, preventing overheating. Here’s how to use a wet tile saw:

– Fill the reservoir with water.

– Adjust the cutting depth according to the thickness of the tile.

– Position the tile on the table, aligning the marked line with the blade.

– Turn on the saw and slowly guide the tile towards the blade, applying gentle pressure.

– Allow the saw to do the cutting without forcing or rushing.

FAQs:

Q1: Can I use a wet tile saw to cut other materials besides ceramic or porcelain?

A1: While wet tile saws are primarily designed for cutting ceramic or porcelain tiles, they can also be used for cutting natural stone, glass, and certain types of mosaics.

Q2: Is it necessary to wear any protective gear when using a wet tile saw?

A2: Yes, it is essential to wear safety goggles, ear protection, and gloves when operating a wet tile saw to protect yourself from potential hazards.

c) Tile Nippers:

Tile nippers are handheld tools used for making small cuts or shaping tiles. They feature two sharp blades that can bite into tiles, allowing you to remove small sections or create irregular shapes.

To use tile nippers effectively:

– Mark the desired shape or cut on the tile – Hold the tile firmly in one hand and position the nippers at the edge of the marked line.

– Squeeze the handles of the nippers together to bite into the tile.

– Gradually squeeze the handles to remove small sections or shape the tile as desired.

– Use caution and make small, controlled cuts to avoid damaging the tile.

– Repeat as necessary until you achieve the desired shape or cut.

FAQs:

Q1: Can I use tile nippers for straight cuts?

A1: Tile nippers are not ideal for straight cuts. They are primarily used for making small or irregular cuts in tiles.

Q2: What types of tiles can be cut with tile nippers?

A2: Tile nippers can be used on various types of tiles, including ceramic, porcelain, and glass. However, they may not be suitable for harder materials like natural stone.

D) Tile Saws:

Tile saws are powered machines that use a circular blade to cut through tiles. They can be either wet or dry saws, depending on whether they use water-cooling or not.

– Wet Tile Saws:

Wet tile saws work similarly to wet tile saws. However, instead of a diamond blade, they use a circular blade with small teeth that cut through tiles with water-cooling. Here’s how to use a wet tile saw:

– Fill the reservoir with water.

– Adjust the cutting depth according to the thickness of the tile.

– Position the tile on the table, aligning the marked line with the blade.

– Turn on the saw and slowly guide the tile towards the blade, applying gentle pressure.

– Allow the saw to do the cutting without forcing or rushing.

– Dry Tile Saws:

Dry tile saws are similar to wet tile saws, but they do not use water-cooling. Instead, they have a dust collection system to minimize dust and debris while cutting. Here’s how to use a dry tile saw:

– Adjust the cutting depth according to the thickness of the tile.

– Position the tile on the table, aligning the marked line with the blade.

– Turn on the saw and slowly guide the tile towards the blade, applying gentle pressure.

– Allow the saw to do the cutting without forcing or rushing.

FAQs:

Q1: Can I use a dry tile saw for wet cutting?

A1: No, dry tile saws are specifically designed for dry cutting only. Using them for wet cutting can damage the saw and affect its performance.

Q2: What type of tile is best suited for dry cutting?

A2: Dry tile saws are suitable for cutting various types of tiles, including ceramic, porcelain, and natural stone. However, some harder materials like granite may require a wet tile saw for better results.

Q3: Can I use a wet tile saw without water?

A3: It is not recommended to use a wet tile saw without water. Water-cooling helps to reduce heat and friction, preventing damage to the blade and ensuring smoother cuts.