Staining is actually probably the most common technique applied to concrete flooring, acid stains are directly put on to the floor to create serious rich colours. Polished concrete flooring has a slew of amazing benefits to home builders and renovators. You can make several geometric shapes and styles to create essentially a patent that you want. The natural color capabilities of concrete will complement any color scheme.

Here are Images about Thin Concrete Floor Slab

Thin Concrete Floor Slab

Wet polishing creates waste slurry which easily spreads into hard-to-find difficult to reach places. On a new concrete, stain concrete floors making companies advise letting the concrete cure for no less than a month. In addition to making polished concrete extremely sustainable, concrete is certainly the cheapest flooring option available.

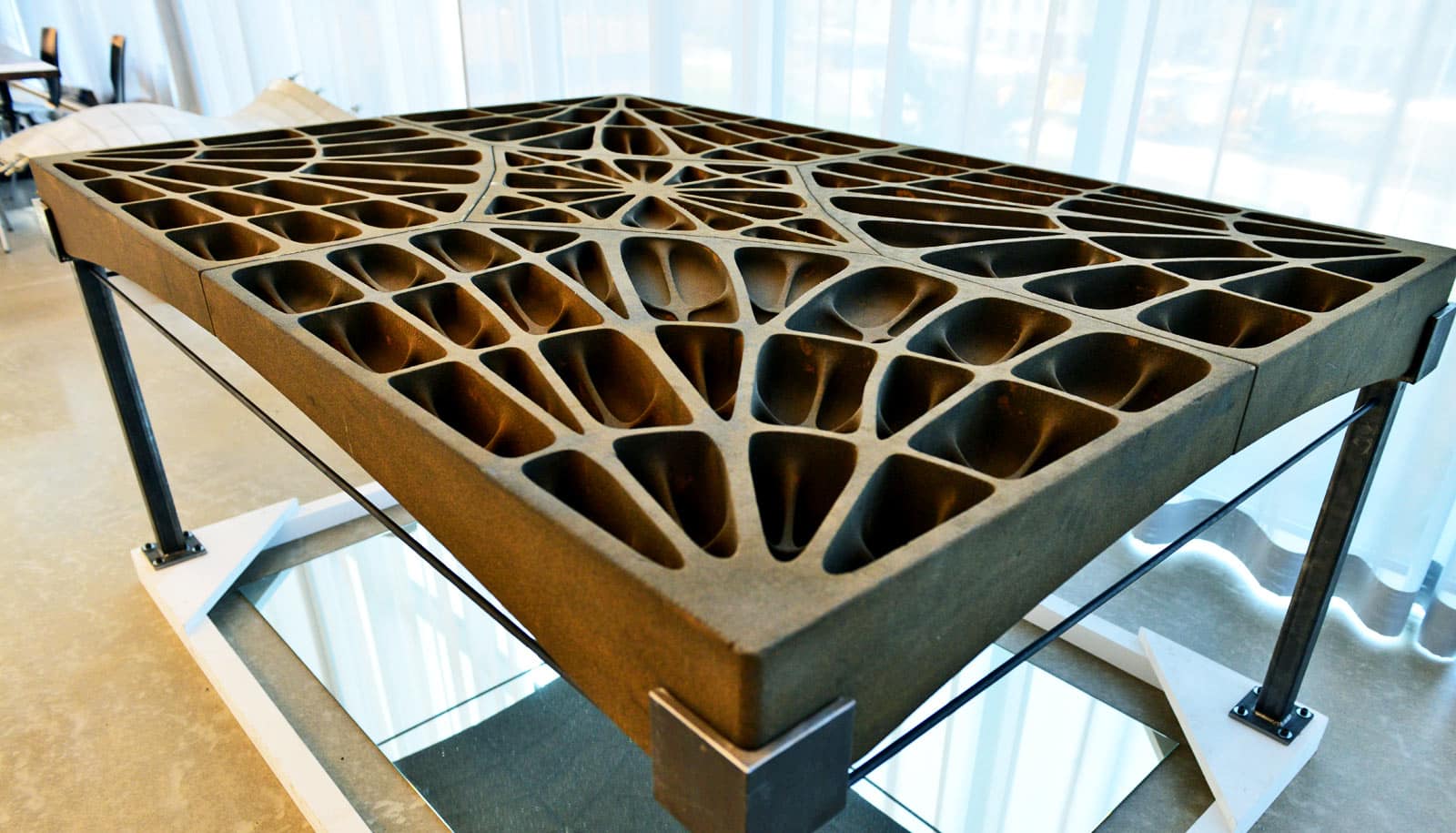

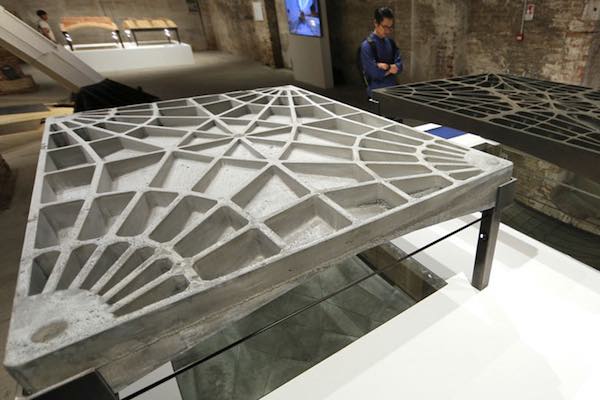

Thin concrete slabs are extruded to bring lightness to this

Polished concrete flooring can be the first step toward creating an allergy-free environment. Polished concrete is turning out to be a preferred office floor option due to its longevity, easy maintenance, and wide choice of colors as well as decorative options. You are able to further mop it using hot, soapy drinking water, but only utilizing a light detergent.

Images Related to Thin Concrete Floor Slab

Can concrete be made as a thin sheet? – Quora

Gothic cathedrals inspire very thin concrete floors – Futurity

Arched design allows concrete floors to go thinner and lighter

How thin is too thin? Evaluating slab thickness in reinforced

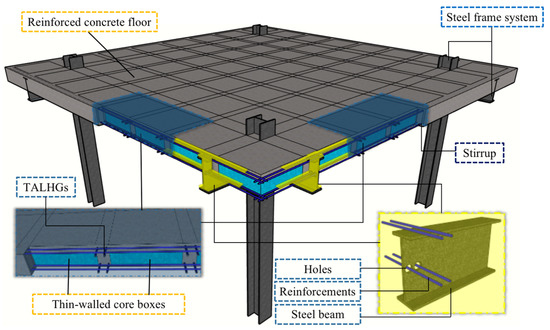

Materials Free Full-Text Behavior of a Two-Way Lightweight

Leimro – Floors

Avoid lightweight concrete for heated slabs 2018-08-28 Supply

Voided slabsu0027 benefits u2013 Geoplast

8: Examples of flexibly-formed concrete floor structures

Block Research Group

Seismic enhancement of R/C buildings by means of a thin cast-in

Thin concrete planes define mountain home in Japan

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

When it comes to constructing a building, one of the most important elements to consider is the flooring. The type of flooring used can greatly affect the overall stability and durability of the structure. One popular choice for flooring in both residential and commercial buildings is a thin concrete floor slab. In this article, we will explore what thin concrete floor slabs are, their benefits, how they are constructed, and some frequently asked questions related to this type of flooring.

What is a Thin Concrete Floor Slab?

A thin concrete floor slab is a type of flooring system that consists of a relatively thin layer of concrete that is poured over a subfloor to create a smooth and durable surface. These floor slabs are typically used in buildings where there is limited space or where a lightweight flooring option is desired. Despite their thin profile, these slabs are incredibly strong and can withstand heavy loads without cracking or breaking.

Benefits of Thin Concrete Floor Slabs

There are several benefits to choosing a thin concrete floor slab for your building project. One of the main advantages is their strength and durability. Despite their thin profile, these slabs are capable of supporting heavy loads and can withstand years of wear and tear without showing signs of damage. Additionally, thin concrete floor slabs are easy to maintain and clean, making them a practical choice for high-traffic areas. Another benefit of these floor slabs is their versatility – they can be customized with various finishes and coatings to achieve the desired aesthetic.

Construction Process

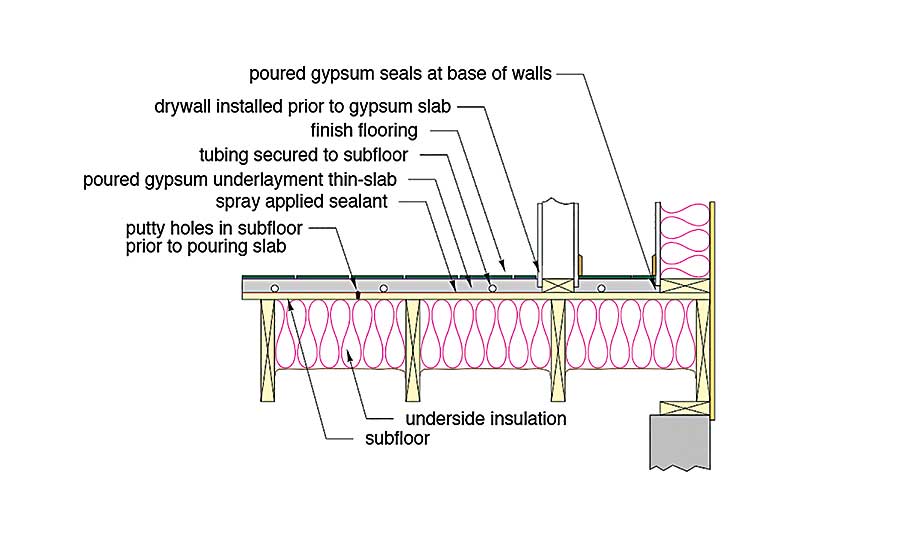

The construction process for a thin concrete floor slab typically begins with preparing the subfloor. This involves ensuring that the subfloor is clean, level, and free of any debris that could interfere with the adhesion of the concrete. Once the subfloor is prepared, a layer of insulation may be added to improve energy efficiency. Next, a moisture barrier is installed to prevent moisture from seeping into the concrete.

After the preparation work is complete, the concrete mixture is poured onto the subfloor and spread evenly using a screed or trowel. The concrete is then allowed to cure and harden before any finishes or coatings are applied. Depending on the desired finish, the surface of the concrete may be polished, stained, or sealed to enhance its appearance and durability.

FAQs

Q: Are thin concrete floor slabs suitable for use in high-traffic areas?

A: Yes, thin concrete floor slabs are an excellent choice for high-traffic areas due to their strength and durability. They can withstand heavy foot traffic without showing signs of wear.

Q: Can thin concrete floor slabs be used in conjunction with radiant heating systems?

A: Yes, thin concrete floor slabs are compatible with radiant heating systems. The thin profile of these slabs allows for efficient heat transfer from the heating elements to the surface of the flooring.

Q: How long does it take for a thin concrete floor slab to cure?

A: The curing time for a thin concrete floor slab can vary depending on factors such as temperature and humidity levels. In general, it takes about 28 days for concrete to fully cure and reach its maximum strength.

In conclusion, thin concrete floor slabs are an excellent choice for both residential and commercial buildings due to their strength, durability, and versatility. By understanding the construction process and benefits of these floor slabs, you can make an informed decision when selecting flooring for your next building project.

Overall, thin concrete floor slabs offer a wide range of benefits that make them a practical and cost-effective flooring option. Their strength, durability, ease of maintenance, and versatility make them suitable for a variety of applications. Whether you are looking to install flooring in a high-traffic area, incorporate radiant heating systems, or simply achieve a sleek and modern aesthetic, thin concrete floor slabs are worth considering for your building project. With the right preparation and construction process, you can enjoy the many advantages that thin concrete floor slabs have to offer.

If you have any further questions or would like to learn more about thin concrete floor slabs, don’t hesitate to reach out to a professional contractor or flooring specialist. They can provide you with expert advice and guidance to help you determine if thin concrete floor slabs are the right choice for your specific needs and requirements. With proper installation and care, thin concrete floor slabs can provide lasting beauty and functionality for many years to come. Consider incorporating them into your next building project for a durable and stylish flooring solution. Q: Can thin concrete floor slabs be customized with different finishes or colors?

A: Yes, thin concrete floor slabs can be customized with a variety of finishes, stains, and colors to suit your design preferences. This allows for endless possibilities in terms of aesthetic appeal and style.

Q: Are thin concrete floor slabs environmentally friendly?

A: Yes, thin concrete floor slabs are considered to be an environmentally friendly option for flooring. Concrete is a sustainable material that can be recycled and reused, making it a green choice for building projects.

Q: How do I maintain and clean thin concrete floor slabs?

A: Thin concrete floor slabs are relatively easy to maintain and clean. Regular sweeping and mopping with a mild detergent or cleaner should suffice to keep the surface looking fresh and clean. Sealing the concrete periodically can also help protect it from stains and moisture penetration.

Q: Can thin concrete floor slabs be repaired if they get damaged?

A: Yes, thin concrete floor slabs can be repaired if they get damaged. Minor cracks or chips can be patched up with specialized concrete repair materials, while larger damages may require professional assistance to ensure proper restoration.

Overall, thin concrete floor slabs are a versatile and durable flooring option that offers many benefits for both residential and commercial applications. With proper care and maintenance, they can provide lasting beauty and functionality for many years to come. Consider incorporating them into your next building project for a stylish and reliable flooring solution.