The floor is often dyed just about any color and area glow can be anywhere between a matte finish to a high gloss. People who are vulnerable to allergies can easily use concrete flooring in their house. Technological advances have prepared polished concrete floor one of the reliable competitors and at present, you are able to look forward to get some spectacular floors.

Here are Images about Suspended Concrete Floor Slab

Suspended Concrete Floor Slab

The mantra is to cover the active concrete floor with a small cement-based overlay to produce a fresh brand new picture to work on. As soon as they have cured, latest concrete installations are inexpensively and easily brought to a gloss. When setting up polished concrete flooring, the concrete is actually sanded with a diamond-surfaced polishing machine.

Concrete slab floors YourHome

Whenever we think of concrete floors, we quite often think of those boring basement floors a dull gray-ish color devoid of pattern or design. This can wind up saving you hours in work as well as cleaning costs. Thus, when you are in the market for flooring, recall concrete flooring isn't only superior to down in health benefits as well as temperature regulation, but highest and eco-friendly also in customer satisfaction.

Images Related to Suspended Concrete Floor Slab

Design of Reinforced Concrete Slabs (Video 1)

BUILDERu0027S ENGINEER: Suspended Ground Floor Slabs.

Suspended Slab, Suspended concrete Slab, Cement slab

Building Guidelines Concrete Floors, Slabs

Suspended Floors – All You Need To Know – Thermohouse

Suspended Concrete Slab, Suspended Slab, Cement Slab

Building Guidelines Drawings. Section B: Concrete Construction

Building Guidelines Drawings. Section B: Concrete Construction

Concrete slab floors YourHome

Evolution of Building Elements

E5MCFF30 Suspended In-Situ Concrete Floor, Insulation Below Slab

Slab On Grade Foundation Design Slab On Grade Design

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Suspended Concrete Floor Slab: An Innovative Solution for Construction Projects

Introduction:

In the realm of construction, suspended concrete floor slabs have gained significant popularity due to their numerous advantages over traditional flooring systems. This innovative solution offers a range of benefits, including increased versatility, improved thermal performance, enhanced fire resistance, and reduced noise transmission. In this article, we will delve into the intricacies of suspended concrete floor slabs, exploring their construction process, key components, and frequently asked questions.

1. What is a Suspended Concrete Floor Slab?

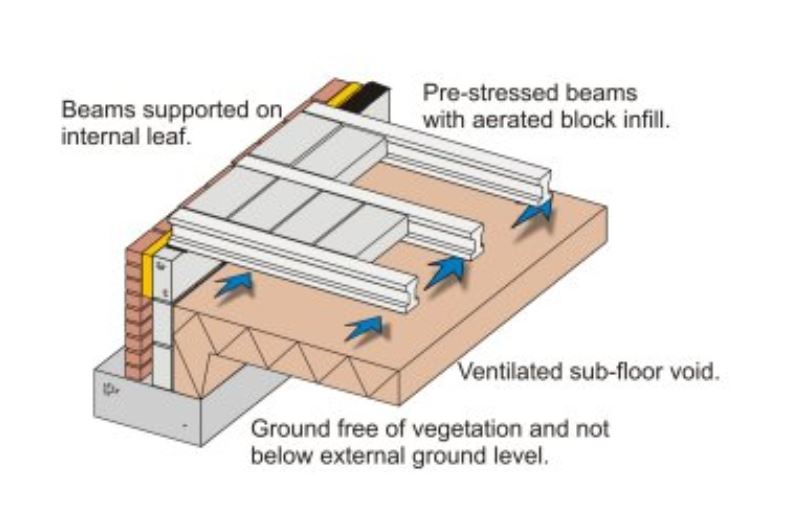

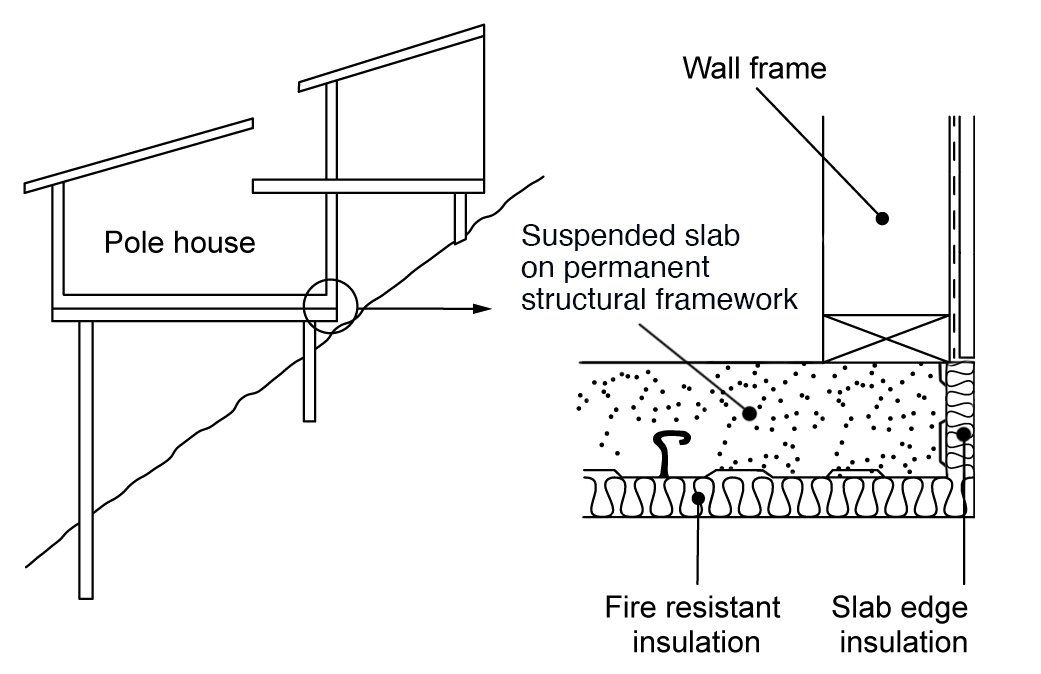

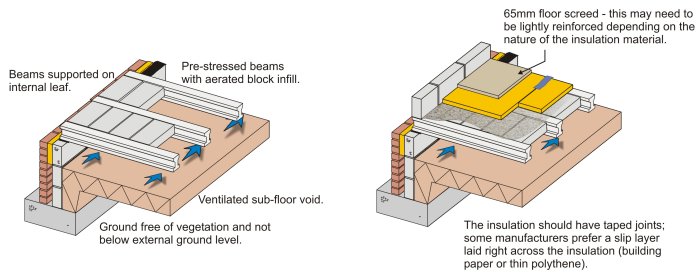

A suspended concrete floor slab refers to a structure that is elevated above ground level, supported by beams or walls underneath. It is commonly used in multi-story buildings as an intermediate floor between two levels. This type of flooring system is often preferred due to its ability to accommodate various services such as electrical wiring, plumbing pipes, and HVAC ducts within the void space created beneath the slab.

2. Construction Process of Suspended Concrete Floor Slabs:

The construction process of suspended concrete floor slabs involves several stages that require meticulous planning and execution. Let’s explore each stage in detail:

a) Design and Structural Analysis:

Before initiating the construction process, it is crucial to conduct a comprehensive structural analysis to determine the load-bearing capacity of the building. This analysis helps engineers design an appropriate suspended concrete floor slab that can withstand the anticipated loads.

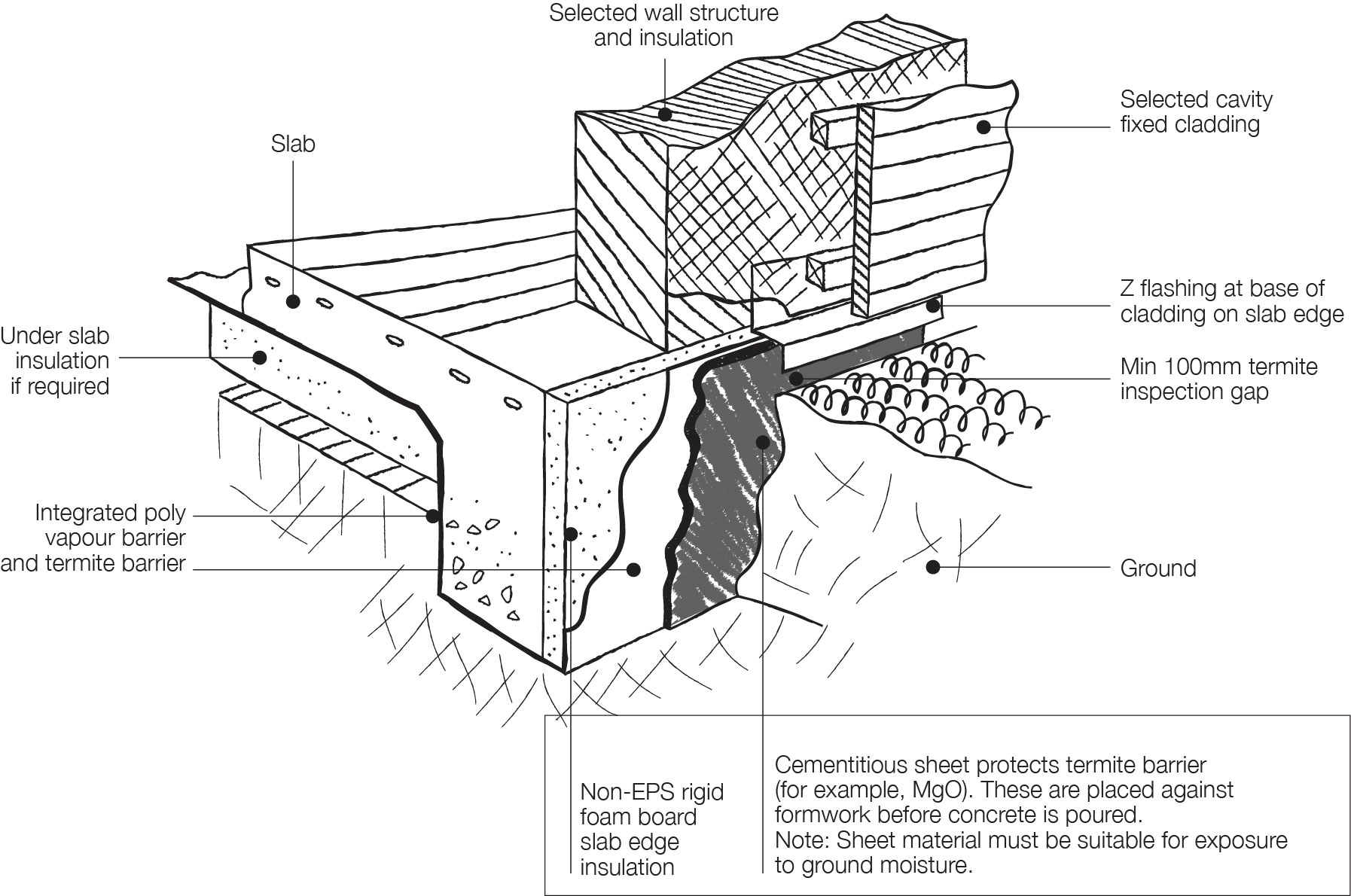

b) Formwork Installation:

Formwork plays a vital role in constructing suspended concrete floor slabs as it provides temporary support during the pouring and curing of concrete. The formwork system consists of horizontal panels, vertical supports, and bracing materials that create a mold for pouring the concrete.

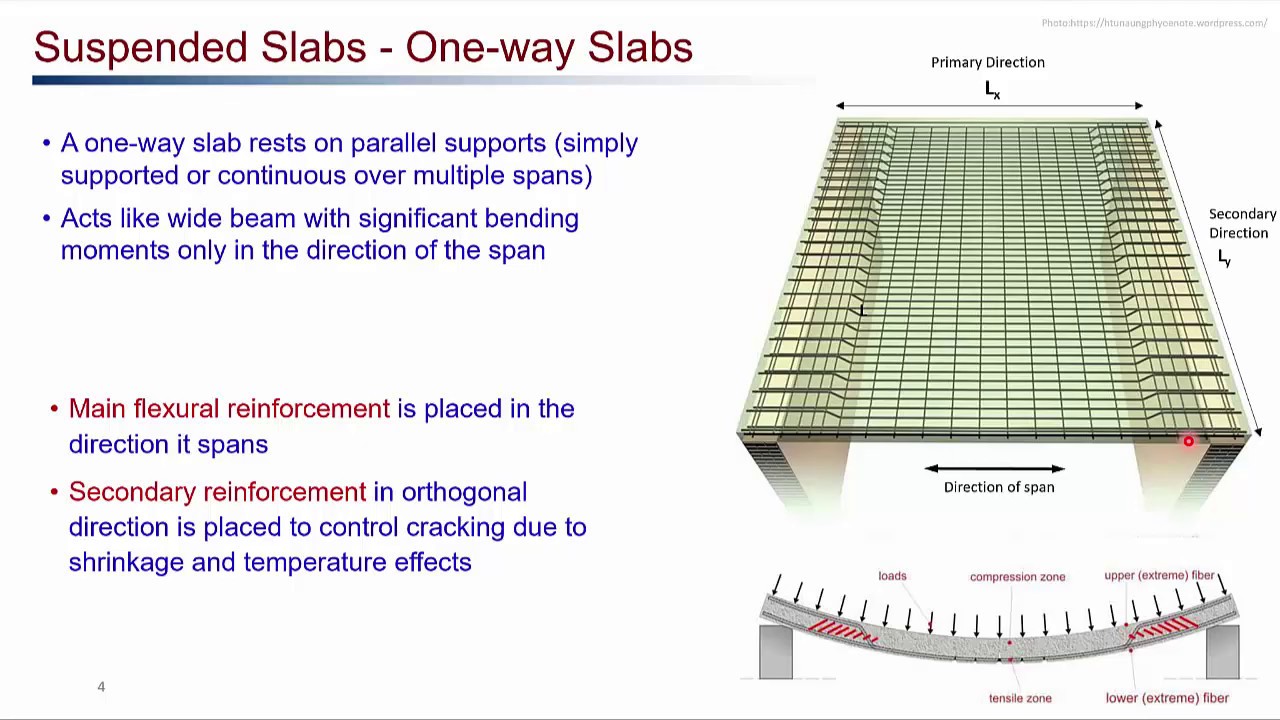

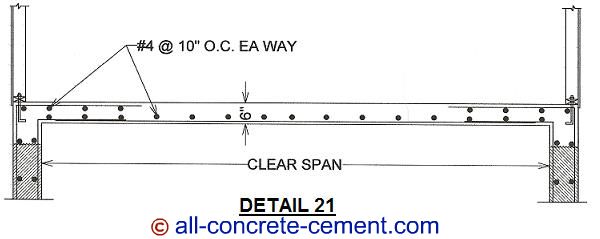

c) Reinforcement Placement:

Reinforcing steel bars (rebars) are crucial components of suspended concrete floor slabs as they enhance its strength and durability. These rebars are placed within the formwork in a predetermined pattern to ensure optimal reinforcement throughout the slab.

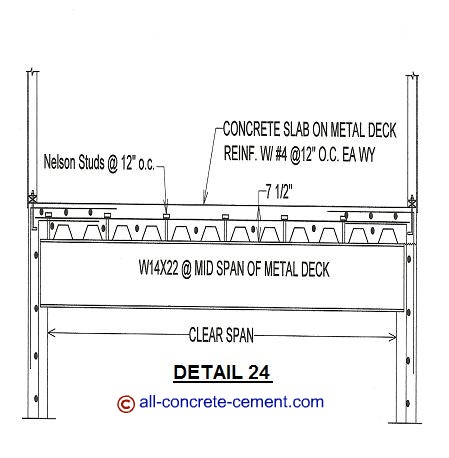

d) Concrete Pouring:

Once the formwork and reinforcement are in place, the next step is to pour the concrete mixture. It is essential to use high-quality concrete with the right mix design to ensure the desired strength and durability of the slab. The concrete is poured into the formwork using a pump or crane, ensuring even distribution throughout the space.

e) Curing and Finishing:

After pouring the concrete, it is crucial to allow it sufficient time to cure and gain strength. Curing involves maintaining an optimal temperature and moisture level to promote proper hydration of the cement. Once cured, the surface of the slab can be finished using various techniques such as polishing or applying a protective coating.

3. Key Components of Suspended Concrete Floor Slabs:

To better understand how suspended concrete floor slabs function, it is important to familiarize ourselves with their key components. Let’s take a closer look at each component:

a) Beams or Walls:

Beams or walls serve as primary support for suspended concrete floor slabs. They are designed to bear the load transferred from the slab and distribute it evenly to the foundation or supporting columns. These structural elements play a crucial role in ensuring the stability and integrity of the entire flooring system.

b) Formwork System:

As mentioned earlier, formwork is a temporary structure used to shape and support freshly poured concrete until it becomes self-supporting. It consists of plywood panels, timber frames, steel supports, and other accessories that provide structural stability during construction. Formwork systems can be modular or custom-designed based on project Requirements.

c) Reinforcement Steel:

Reinforcement steel, commonly known as rebars, is used to enhance the strength and durability of suspended concrete floor slabs. These steel bars are placed within the formwork in a predetermined pattern to provide structural integrity and prevent cracking or failure under load. The size and spacing of rebars are determined by structural engineers based on the anticipated loads and design requirements.

d) Concrete Mixture:

The concrete mixture used for suspended concrete floor slabs should have the right mix design to ensure the desired strength, workability, and durability. The mix typically consists of cement, aggregates (such as sand and gravel), water, and additives. The proportions of these components vary depending on factors such as load requirements, environmental conditions, and desired finish.

e) Finishing Materials:

After the concrete has cured, various finishing materials can be applied to the surface of suspended concrete floor slabs. This includes techniques such as polishing, staining, or applying protective coatings. These finishing materials not only enhance the aesthetics of the floor but also provide additional protection against wear and tear.

In conclusion, constructing suspended concrete floor slabs involves several important steps, including structural analysis, formwork installation, reinforcement placement, concrete pouring, curing, and finishing. Each of these steps is crucial in ensuring the strength, durability, and stability of the floor system. By understanding the key components involved in this construction process, engineers can design and construct high-quality suspended concrete floor slabs that meet project requirements. A) Beams or Walls: These components provide support for the suspended concrete floor slabs and distribute the load to the foundation or supporting columns.

b) Formwork System: Formwork is a temporary structure that shapes and supports freshly poured concrete until it becomes self-supporting. It consists of plywood panels, timber frames, steel supports, and other accessories to provide structural stability during construction.

c) Reinforcement Steel: Also known as rebars, reinforcement steel enhances the strength and durability of suspended concrete floor slabs. These steel bars are placed within the formwork in a predetermined pattern to provide structural integrity and prevent cracking or failure under load.

d) Concrete Mixture: The concrete mixture used for suspended concrete floor slabs should have the right mix design to ensure desired strength, workability, and durability. It typically consists of cement, aggregates (such as sand and gravel), water, and additives.

e) Finishing Materials: Various finishing materials can be applied to the surface of suspended concrete floor slabs after curing. This includes techniques such as polishing, staining, or applying protective coatings to enhance aesthetics and provide additional protection against wear and tear. F) Load Requirements: The design of suspended concrete floor slabs must take into consideration the expected load that the floor will bear. This includes both dead loads (the weight of the floor itself and any permanent fixtures) and live loads (the weight of people, furniture, and other temporary loads).

g) Environmental Conditions: The environmental conditions, such as temperature and humidity, can affect the curing process of the concrete and the overall durability of the floor. Special considerations may need to be taken in extreme climates or in areas with high moisture levels.

h) Desired Finish: The desired finish of the suspended concrete floor slabs will determine the type of finishing materials and techniques used. This can range from a smooth polished surface to a textured or decorative finish.

i) Curing Process: After the concrete is poured, it needs to be properly cured to reach its maximum strength. This typically involves keeping the concrete moist and at a consistent temperature for a specified period of time.

j) Safety Measures: Safety measures should be implemented during the construction process to ensure the well-being of workers and prevent accidents. This may include providing proper scaffolding, fall protection, and training for workers.

k) Quality Control: Regular quality control measures should be in place to ensure that all components of the suspended concrete floor slabs meet industry standards and project specifications. This may involve conducting tests on the concrete mixture, reinforcement steel, and finished floor.

Overall, constructing suspended concrete floor slabs requires careful planning, attention to detail, and adherence to industry standards. By considering these key factors, engineers can create durable and functional floors that meet both aesthetic and structural requirements.