Concrete floors usually get cold especially on colder temperature so before the cement combination is poured on the flooring, sparkling floor pipes or flexible tubing are actually for starters laid on the surface. When you're searching for a flooring solution for your home project that combines elegance and simplicity, then you certainly will want to investigate polished concrete floors.

Here are Images about Solid Concrete Floor Construction Details

Solid Concrete Floor Construction Details

Individuals used to believe that concrete floors looked cheap, as if you could not find the money carpet or maybe various other covering. Apart from this energy efficiency, concrete flooring is also environmentally friendly. By periodically washing concrete floor, business people can help hold the inherent beauty of concrete flooring while extending the lifespan of its.

Solid ground floor – Wikipedia

Polished concrete flooring is one of the cheapest options as in comparison to other material used for flooring today. It does work with the lime content in the floor it is quite unpredictable but generally comes out looking quite good. It's additionally a good idea to survey the concrete floor often and get rid of any unwanted substances, such as stickers or gum, and inspect it for damage.

Images Related to Solid Concrete Floor Construction Details

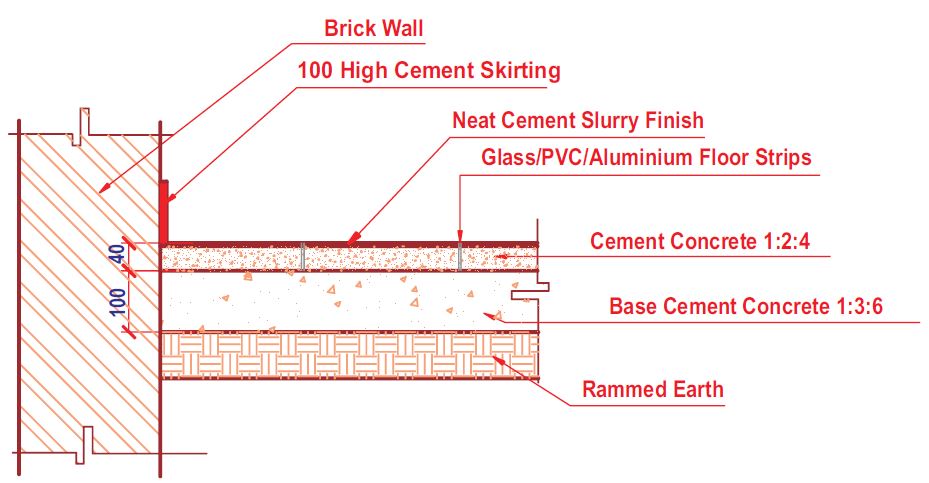

11-Construction detail of the concrete slab-on-ground floored case

HOW TO CONSTRUCT CEMENT CONCRETE FLOOR? – CivilBlog.Org

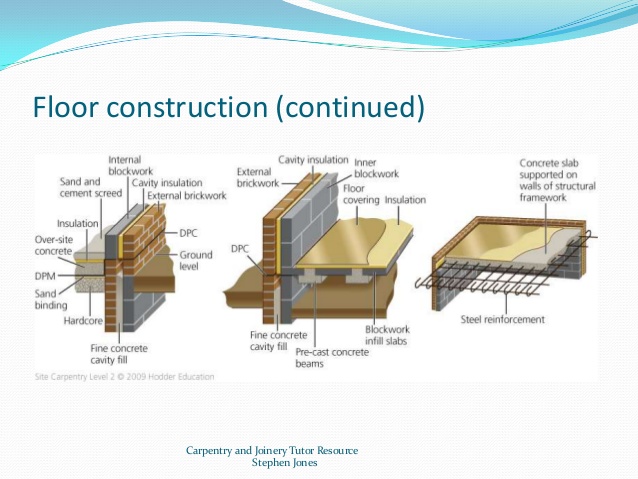

6. Ground Floors – Construction Studies

Laying a Concrete Floor – DIY Extra

Concrete slab floor construction BRANZ Renovate

6. Ground Floors – Construction Studies

11-Construction detail of the concrete slab-on-ground floored case

Floors – Types of floors – Methods of Construction of Floor

Building Guidelines Drawings. Section B: Concrete Construction

Qu0026A: Solid Wood Floors Over Concrete Slabs JLC Online

Concrete Floor Slab Construction Process – The Constructor

Building Guidelines Drawings. Section B: Concrete Construction

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Solid concrete floors have been used in construction for centuries, lending strength and durability to the underlying structure. In recent years, advances in technology have made it easier than ever to create solid concrete flooring that provides a beautiful, long-lasting foundation for any building project. This article will cover the details of solid concrete floor construction, from the initial design phase to the finished product.

Design Considerations

The first step when constructing a solid concrete floor is to consider the design requirements. This includes factors such as the desired thickness of the floor, the type of aggregate and finish material used, and any special load requirements. As a general rule, thicker floors are more durable and can carry heavier loads, while thinner floors are better suited for lighter duty applications. When selecting an aggregate material, it is important to keep in mind that materials with larger particles, such as gravel or crushed stone, are more prone to cracking over time than smaller particles such as sand.

Formwork

Once the design of the floor has been determined, formwork must be constructed. Formwork is a temporary structure that is built to shape and support the wet concrete until it has hardened. Common materials used for formwork include plywood, steel, plastic or fiberglass. It is important to ensure that the formwork is properly sealed and waterproofed to prevent moisture from seeping through and damaging the concrete.

Rebar

After the formwork has been installed, reinforcing steel bars (known as “rebar”) should be placed inside. Rebar helps to strengthen the concrete by providing additional support and preventing cracking due to shrinkage or shifting of the structure. It is important to use rebar that has been treated with rust-proofing material to prevent corrosion over time.

Pouring

Once all of the necessary components are in place, it is time to pour the concrete. The concrete should be mixed in a proper ratio and poured evenly into the formwork. A vibrating tool can be used to help ensure that there are no air pockets or voids left in the mix. The concrete should then be leveled off with a trowel or screed board before it begins to set.

Finishing

After the concrete has hardened, it is time to finish the surface. This usually involves troweling or polishing with a power trowel or grinding machine. Depending on the desired look, an aggregate material such as sand or pebbles may also be added before finishing begins. Finishing can also include adding a sealer or stain to protect the floor from water damage and staining.

Common Questions and Answers

Q: What type of aggregate should I use for my concrete floor?

A: The type of aggregate used depends on your specific design requirements and desired finished look. Generally speaking, larger particles such as gravel or crushed stone are more prone to cracking than smaller particles such as sand.

Q: How thick should my solid concrete floor be?

A: The thickness of your solid concrete floor will depend on your specific design requirements and intended purpose for the floor. As a general rule, thicker floors are more durable and can carry heavier loads than thinner floors.

Q: How do I ensure my finished solid concrete floor looks good?

A: After pouring and hardening your concrete floor, it is important to finish the surface properly using troweling or grinding machines. Additionally, adding an aggregate material before finishing may help you achieve your desired look, while applying a sealer or stain can protect your floor from water damage and staining over time.