The polished concrete prints fast getting a typical problem in a lot of places across the world and this is partially because many people are actually appreciative of it beauty as well as since many instances just can't stand having other floor types. Sealed concrete has an extremely low environmental impact.

Here are Images about Precast Concrete Floor Construction

Precast Concrete Floor Construction

Thus concrete flooring has become the very first choice of not the homeowner but perhaps the business and business owner. In winter, it becomes more dry and retains the warmth of the sunshine. The appeal would be that when it comes to polished concrete flooring, one particular can be sure that the original appearance will be able to be reinstated. The diamond concrete polishing operation is simple and easy.

STRUCTURE magazine Creating an Opening in Existing Floors

When necessary, consider re applying the sealant as this is going to go a long way to improving the life expectancy as well as the design of the concrete floor. The initial step before considering some tips and tricks is figuring out what sort of concrete you've. The newest technology to create the boring of yours and flat concrete flooring into a polished and shiny mirror.

Images Related to Precast Concrete Floor Construction

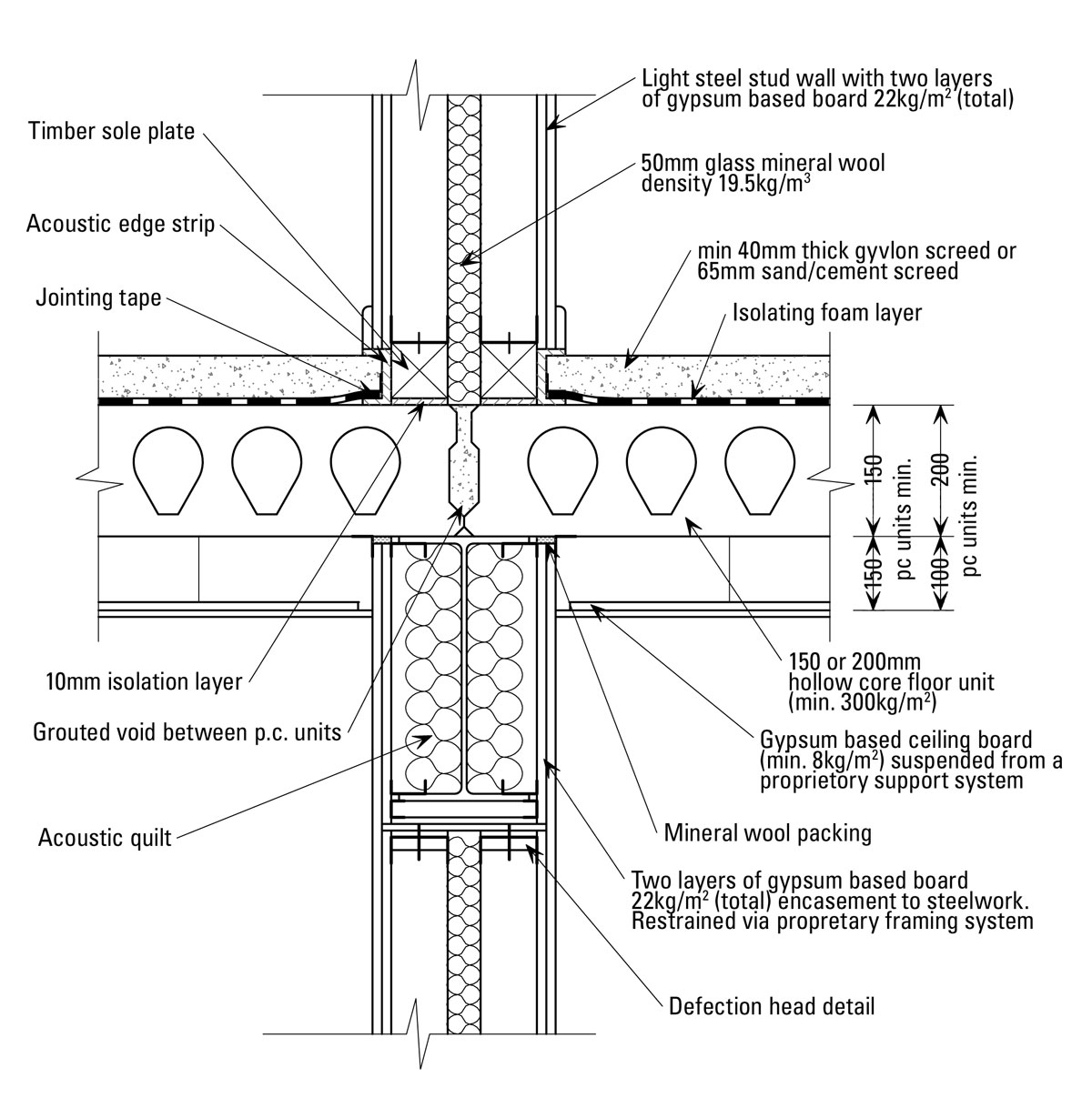

AD 313: Precast concrete floors in steel framed buildings

Hollowcore Residential Applications

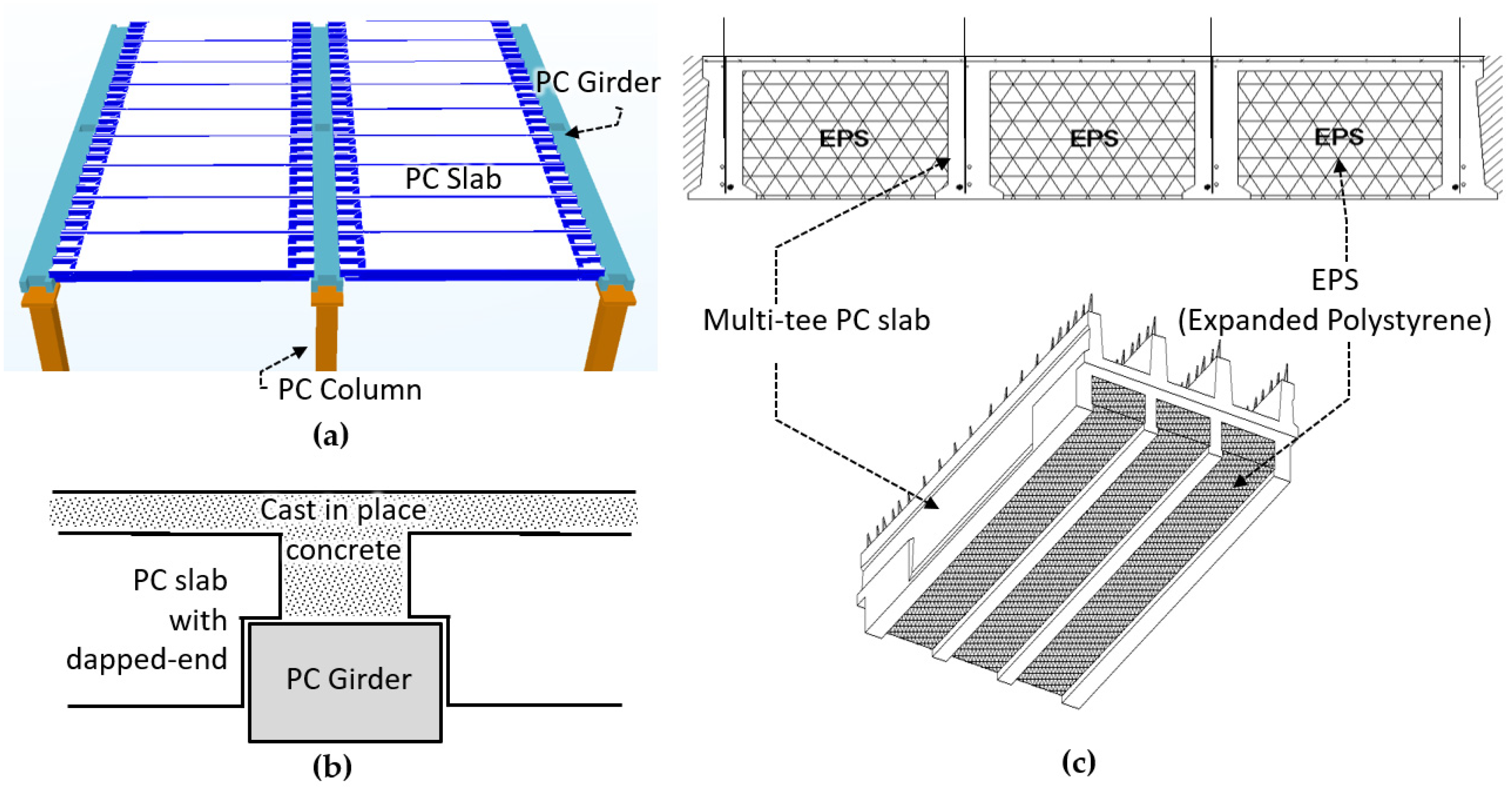

Applied Sciences Free Full-Text Development of Multi-Tee-Type

PreCast Construction Precast concrete, Precast concrete slabs

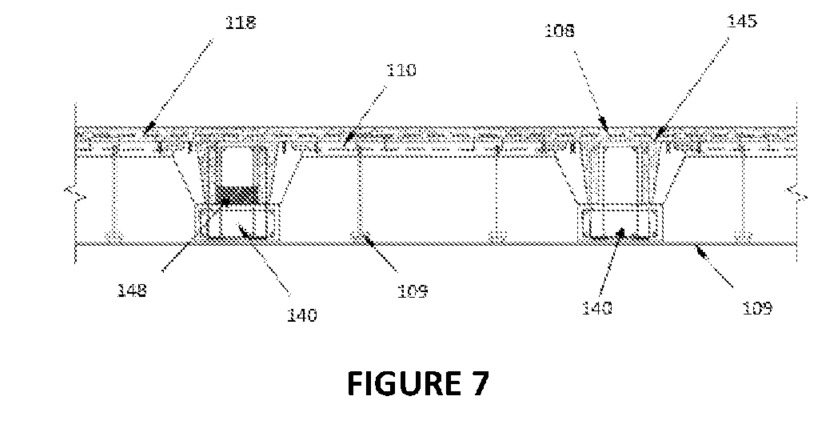

Precast concrete formwork, floor system and a method of

65 Precast concrete floors – Steel Construction – Beyond Discovery

Hollow-core slab – Wikipedia

Taxonomy – Precast concrete floor with reinforced concrete topping

Precast Concrete – an overview ScienceDirect Topics

Situ Concrete – an overview ScienceDirect Topics

Opportunities for precast prestressed concrete floor slabs in

Strong Iron Wire On Precast Concrete Slabs Prepare For Reinforce

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Precast concrete flooring is a popular choice in commercial and residential construction due to its durability, cost-effectiveness, and quick installation. It’s also a great option for those looking to reduce building costs and environmental impact. Here’s everything you need to know about precast concrete floor construction.

What is Precast Concrete Flooring?

Precast concrete flooring is a type of concrete slab that is produced off-site in a factory and then installed on-site. It is made using a cast-in-place method, which means the concrete is poured into a mold, allowed to set, and then removed from the mold. It is typically reinforced with steel rebar or wire mesh for additional strength.

Advantages of Precast Concrete Flooring

There are numerous advantages to using precast concrete flooring, including:

– Quick installation: Precast concrete flooring can be quickly installed due to its pre-made components. This makes it ideal for time-sensitive projects.

– Reduced labor costs: The pre-made components of precast concrete flooring make it easier and faster to install than traditional concrete slabs, which can save on labor costs.

– Long lifespan: Precast concrete flooring is extremely durable and can last up to 50 years or more with proper maintenance.

– Reduced environmental impact: Precast concrete flooring is made from recycled materials, making it an eco-friendly choice for construction projects.

What Are the Steps Involved in Installing Precast Concrete Flooring?

Installing precast concrete flooring requires several steps:

1. Prepare the subfloor: The subfloor must be leveled and prepared before installing the precast concrete flooring.

2. Place the precast slabs: The precast slabs are placed into position on the prepared subfloor using a crane or other lifting equipment.

3. Level the slabs: The precast slabs must then be leveled to ensure an even surface when finished.

4. Secure the slabs: The slabs must then be secured into place by either bolting them down or pouring grout between them.

5. Finish the installation: Once the slabs are secured, they must be finished with a sealant or other protective coating to protect them from moisture, stains, and other damage.

What Are the Benefits of Precast Concrete Floor Construction?

Precast concrete floor construction offers numerous benefits, such as:

– Cost savings: Precast concrete floor construction is more cost effective than other methods of floor construction due to its quick installation time and reduced labor costs.

– Durability: Precast concrete floor construction is extremely durable and can last up to 50 years or more with proper maintenance.

– Versatility: Precast concrete floors can be installed in any shape or size and can be customized for unique designs or needs.

– Environmental impact: Precast concrete floors are made from recycled materials, making them an eco-friendly choice for construction projects.

Conclusion

Precast concrete floor construction is an efficient and cost effective way to build strong, durable floors quickly and easily. With its numerous advantages and benefits, it’s no wonder why so many people are choosing precast concrete for their construction projects!