If the household doesn't wish to do it themselves they're able to contact epoxy flooring business enterprises to do the job. Obviously the expense of this flooring type is justified by the durability of its since as soon as it's been laid it will last a life time. Attempt to get the same color of epoxy level so that it matches with the rest of the floor.

Here are Images about Poured Epoxy Flooring

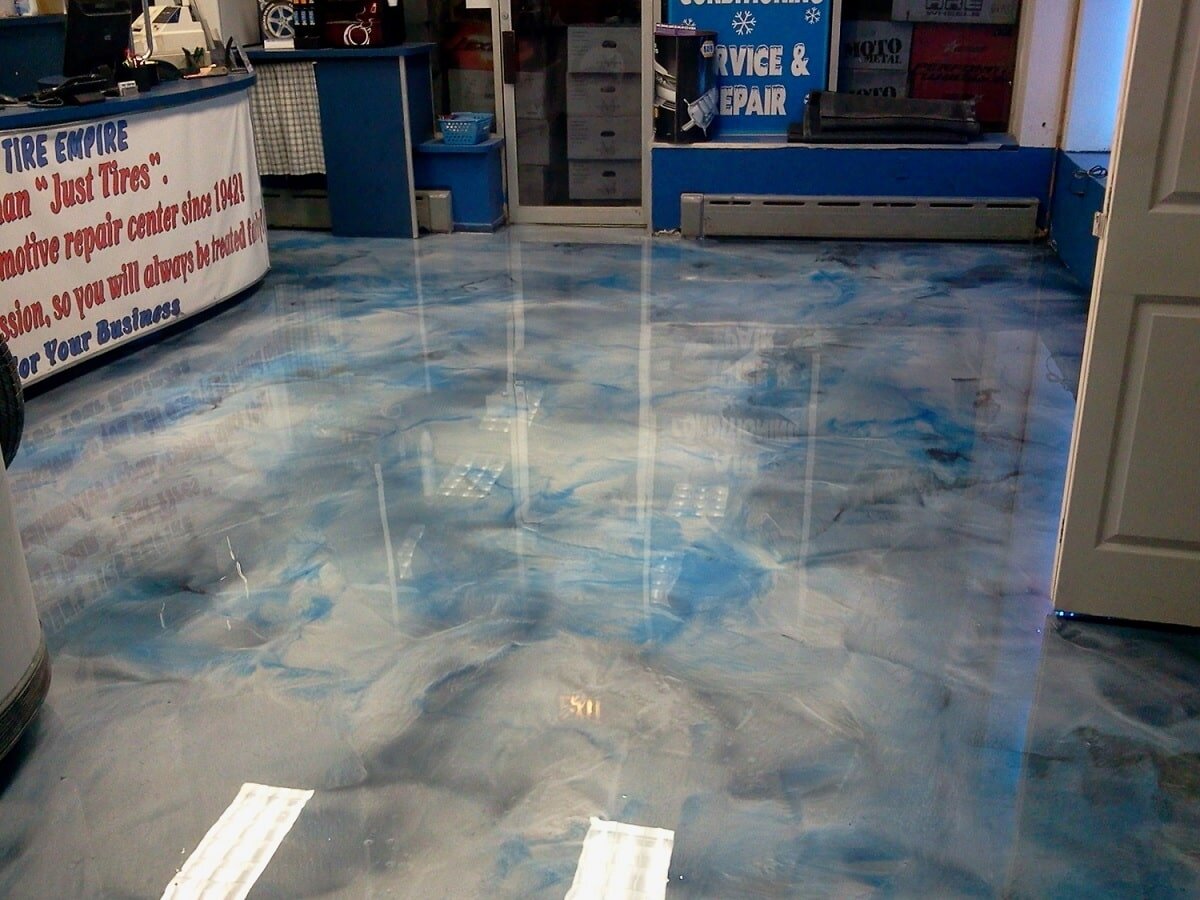

Poured Epoxy Flooring

One other reason this- Positive Many Meanings- epoxy flooring is on a short list for designers is that it could be easily personalized. Epoxy floorings are floorings applied with tiers of rough, long lasting coating referred to as epoxy. The homeowner also can enjoy a clear epoxy coating poured over ready hardwood floors. It's crucial that the epoxy is mixed properly to ensure correct curing.

Do-It-Yourself Epoxy Floor Coating

Epoxy floors are available in all types of varieties & styles. On the flip side, if you have a brand new slab, wait for no less than a month for the flooring to be thoroughly dry just before epoxy application. Actually the epoxy paints could be offered desired textures too. You'll find a lot of advantages in employing epoxy as a floor coating. The price of an epoxy floor is comparable to that of other flooring sorts.

Images Related to Poured Epoxy Flooring

Understanding the Pros and Cons of Epoxy Floors

Epoxy Flooring: What You Must Know u0026 Should Avoid

Lifetime Epoxy Flooring Blog – Lifetime Epoxy Floor Coatings

Everlast Epoxy Flooring for Wide Range of Commercial u0026 Industrial

Is Epoxy Flooring Safe For My Home? Epoxy Colorado

Epoxy Flooring – Perfect Polish Concrete

The Pros and Cons of Epoxy Floors in Your House – Advance

Manhattan Epoxy Flooring Installation u0026 Contractor: Seamless Floors

Metallic Epoxy Tips and Techniques – Concrete Decor

Epoxy Flooring: What You Must Know u0026 Should Avoid

Metallic Epoxy Floors Lquified Metal Atlanta Epoxy Floors

Epoxy Flooring: What to Consider Before Choosing Epoxy Better

Related articles:

- Metallic Epoxy Floor Designs

- Epoxy Flooring Contractors

- Epoxy Floor Coating Material

- Epoxy Floor Coating With Flakes

- Epoxy Floor Finishes Concrete

- Epoxy Flooring Design

- DIY Epoxy Flooring Systems

- Epoxy Floor Coating Designs

- Epoxy Flooring Basement

- Artistic Epoxy Flooring

Poured Epoxy Flooring: Achieving Aesthetic and Functional Excellence

Introduction:

In recent years, poured epoxy flooring has gained popularity as a versatile and durable flooring option for both residential and commercial spaces. Its seamless, glossy finish creates a visually striking impact while providing various functional benefits. This article aims to delve into the world of poured epoxy flooring, exploring its features, installation process, maintenance requirements, and frequently asked questions to help you make an informed decision when considering this flooring solution for your next project.

I. Understanding Poured Epoxy Flooring:

Poured epoxy flooring is a type of resinous flooring system that combines epoxy resin with a hardener to create a chemical reaction resulting in a solid, smooth surface. Known for its high-performance characteristics and aesthetic appeal, this floor coating can transform any space into a stunning and functional environment.

The Benefits of Poured Epoxy Flooring:

1. Durability:

Poured epoxy flooring boasts exceptional durability, making it ideal for high-traffic areas such as retail stores, hospitals, schools, and industrial facilities. It is resistant to heavy impacts, scratches, stains, and chemicals. The robust nature of poured epoxy ensures longevity and reduces the need for frequent repairs or replacements.

FAQ: Can poured epoxy flooring withstand heavy machinery in industrial settings?

Answer: Yes, poured epoxy flooring is specifically designed to withstand heavy machinery and equipment commonly found in industrial environments. Its high compressive strength ensures durability even under substantial weight loads.

2. Versatility:

One of the most appealing aspects of poured epoxy flooring is its versatility in design options. It can be customized to suit various aesthetics and purposes. Available in numerous colors, patterns, finishes, and even 3D designs, poured epoxy allows you to unleash your creativity while achieving a unique look for your space.

FAQ: Is it possible to create custom logos or branding with poured epoxy flooring?

Answer: Absolutely! Poured epoxy flooring offers endless possibilities for customization, including the incorporation of logos, branding elements, and even intricate patterns. These designs can be seamlessly integrated into the flooring, creating a distinctive visual impact.

3. Seamless and Hygienic:

Unlike traditional flooring options that have seams or grout lines where dirt and bacteria can accumulate, poured epoxy flooring provides a seamless surface. This feature not only enhances its aesthetic appeal but also makes cleaning and maintenance a breeze. Additionally, epoxy is resistant to moisture, mold, and mildew, making it an excellent choice for areas prone to spills or humidity.

FAQ: Is poured epoxy flooring suitable for kitchens and bathrooms?

Answer: Absolutely! Poured epoxy flooring is an ideal choice for kitchens and bathrooms due to its seamless nature and resistance to moisture. It prevents water from seeping into the subfloor and keeps these areas hygienic by inhibiting the growth of mold and mildew.

II. The Installation Process:

1. Surface Preparation:

The key to a successful poured epoxy flooring installation lies in thorough surface preparation. Firstly, the existing floor must be cleaned of any debris, grease, or stains. Next, any cracks or imperfections should be repaired using epoxy or concrete fillers. Finally, the floor may require mechanical grinding or shot blasting to create a roughened surface for better adhesion.

2. Primer Application:

After surface preparation, a primer coat is applied to ensure proper bonding between the existing floor and the epoxy resin. The primer penetrates the substrate, sealing it and enhancing adhesion.

3. Epoxy Resin Application:

Once the primer Is dry, the epoxy resin can be mixed and applied to the prepared surface. This is typically done using a roller or squeegee to achieve an even coat. Multiple layers may be necessary depending on the desired thickness and durability.

4. Optional Decorative Elements:

If desired, decorative elements such as color flakes or metallic pigments can be added to the wet epoxy resin. These elements can enhance the aesthetic appeal of the flooring and create a unique look.

5. Topcoat Application:

After the epoxy resin has cured, a topcoat is applied to provide additional protection and durability. This coat also adds a glossy or matte finish, depending on the desired look.

6. Curing and Drying:

Once all layers have been applied, the poured epoxy flooring needs time to cure and dry fully. This process typically takes several days, during which foot traffic should be avoided.

7. Regular Maintenance:

To ensure the longevity of poured epoxy flooring, regular maintenance is necessary. This includes routine cleaning using non-abrasive cleaners and periodic reapplication of topcoat to maintain its protective layer.

Overall, poured epoxy flooring is a durable, versatile, and hygienic option for industrial and commercial spaces. Its installation process requires thorough surface preparation and proper application techniques to achieve a seamless and long-lasting result. With proper maintenance, poured epoxy flooring can withstand heavy machinery and provide a visually appealing surface for years to come. The installation process for poured epoxy flooring involves several steps to ensure a successful and long-lasting result. Here is a breakdown of the process:

1. Surface Preparation: The existing floor must be thoroughly cleaned of any debris, grease, or stains. Cracks or imperfections should be repaired using epoxy or concrete fillers. Mechanical grinding or shot blasting may be necessary to create a roughened surface for better adhesion.

2. Primer Application: After surface preparation, a primer coat is applied to enhance bonding between the existing floor and the epoxy resin. The primer penetrates the substrate, sealing it and improving adhesion.

3. Epoxy Resin Application: Once the primer is dry, the epoxy resin is mixed and applied to the prepared surface using a roller or squeegee. Multiple layers may be necessary depending on the desired thickness and durability.

4. Optional Decorative Elements: If desired, decorative elements such as color flakes or metallic pigments can be added to the wet epoxy resin to enhance the aesthetic appeal of the flooring.

5. Topcoat Application: After the epoxy resin has cured, a topcoat is applied for additional protection and durability. This coat also adds a glossy or matte finish, depending on the desired look.

6. Curing and Drying: Once all layers have been applied, the poured epoxy flooring needs time to cure and dry fully. This process typically takes several days, during which foot traffic should be avoided.

7. Regular Maintenance: To ensure the longevity of poured epoxy flooring, regular maintenance is necessary. This includes routine cleaning using non-abrasive cleaners and periodic reapplication of topcoat to maintain its protective layer.

Overall, poured epoxy flooring is a durable, versatile, and hygienic option for industrial and commercial spaces. Proper surface preparation and application techniques are essential for achieving a seamless and long-lasting result. With regular maintenance, poured epoxy flooring can withstand heavy machinery and provide an aesthetically appealing surface for years to come.