The polished concrete prints fast becoming a standard issue in a lot of places across the planet and this is partially because a lot of folks are appreciative of the beauty of its and in addition since many places only can’t stand having other kind of floor. Sealed concrete has an incredibly low environmental impact.

Here are Images about Lightweight Concrete Floor Thickness

Lightweight Concrete Floor Thickness

Polished concrete floors are an excellent strategy of flooring which are increasingly becoming a method of life for many home as well as business people. Polished concrete floors also have quite a few advantages making them an environmentally friendly, affordable and practical solution for housing and apartments. In room and shop settings, concrete floor is less loud than floorboards of tiles.

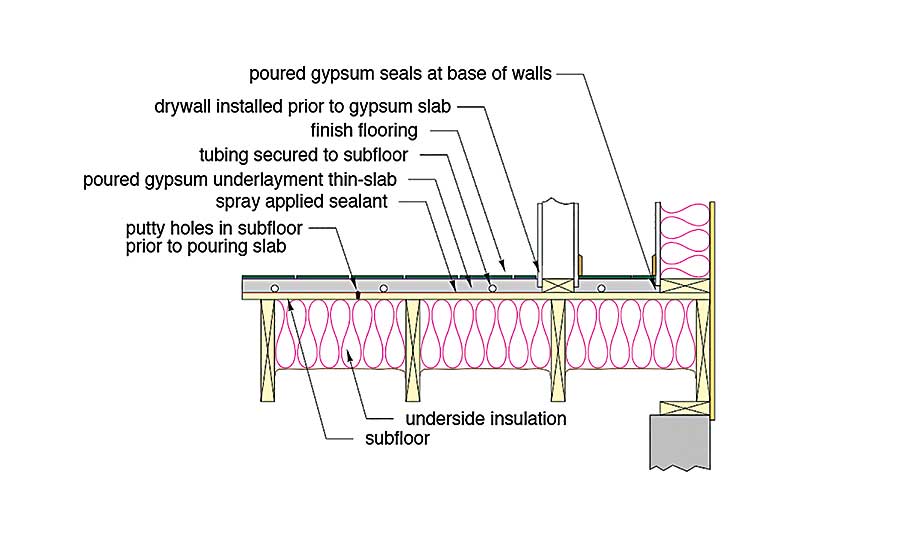

Avoid lightweight concrete for heated slabs 2018-08-28 Supply

Stained concrete floors are stained with colors to complement some decoration. When certain dust collects on the polished concrete floors, it’s far better to lightly clean it off before it can gather to amounts that will call for a little scrubbing of kinds. Once the chemical reaction requires place, staining concrete floors deal with an irreversible bond with the concrete and will not peel away.

Images Related to Lightweight Concrete Floor Thickness

Lightweight Concrete Floor Systems – Thickness, Uses – The Constructor

STRUCTURE magazine Is Lightweight Concrete All Wet?

Lightweight Concrete Floor Systems – Thickness, Uses – The Constructor

STRUCTURE magazine Is Lightweight Concrete All Wet?

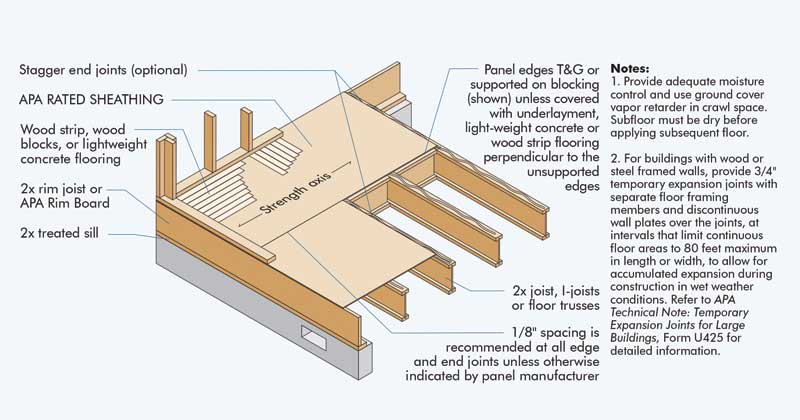

Better floor performance starts with a solid subfloor system

The evolution of composite flooring systems: applications, testing

Concrete Topping Slab -Types, Thickness and Uses – The Constructor

Concrete Calculator How To Calculate Concrete

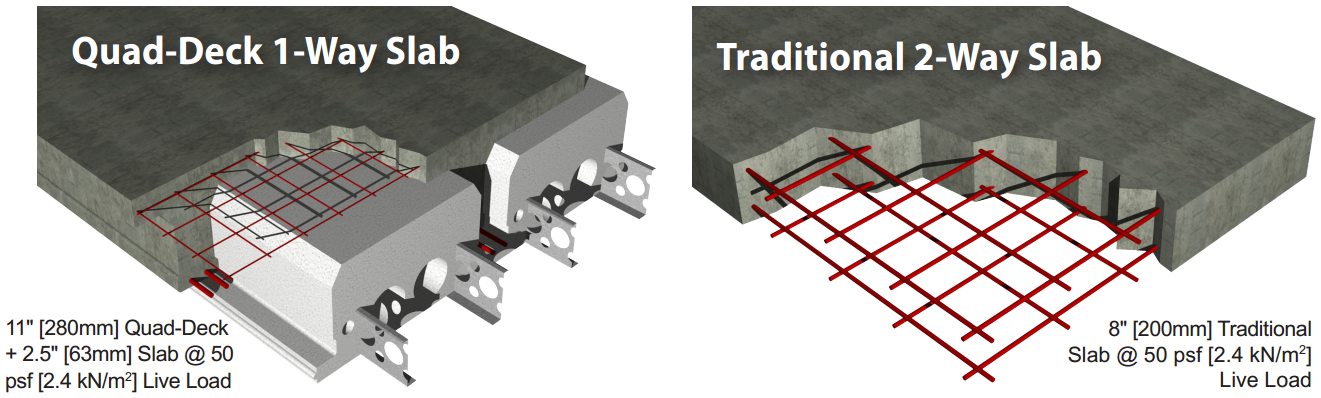

Quad-Deck Insulated Concrete Forms for Floors and Roofs

Concrete Floor Slabs Concrete Construction Magazine

Metal Deck For Concrete: Types u0026 Uses of Composite And Form Decking

-3.png)

Lightweight Concrete Floor Systems – Thickness, Uses – The Constructor

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Lightweight Concrete Floor Thickness: Everything You Need to Know

Lightweight concrete is a versatile and cost-effective solution for any flooring project. It is easy to work with and can be formed into different shapes and sizes. It is also suitable for many indoor and outdoor applications. But one of the most important considerations when working with lightweight concrete is the required floor thickness. In this article, we will explore the recommended thickness of lightweight concrete floors and the factors that influence it.

What is Lightweight Concrete?

Lightweight concrete is a type of concrete made with lightweight aggregates like expanded clay, shale, or slate that has been fired at high temperatures. This process makes the aggregates much lighter than traditional concrete, which gives it its name. Lightweight concrete also has a higher insulation value than regular concrete, making it an excellent choice for projects like flooring in colder climates.

How Thick Should a Lightweight Concrete Floor Be?

The required thickness of a lightweight concrete floor depends on several factors, including the type of application and the type of aggregate used. Generally speaking, a lightweight concrete floor should be between 3 and 5 inches thick for residential applications and up to 8 inches thick for commercial applications. Of course, these are only general guidelines and your contractor may recommend a thicker floor for certain applications.

What Factors Influence the Required Floor Thickness?

The required thickness of a lightweight concrete floor depends on several factors, including the strength of the material, the type of aggregate used, and the load-bearing requirements of the project. For instance, if you are creating a floor in an area with heavy foot traffic or vehicles, your contractor may recommend increasing the thickness of the floor to provide added strength and stability.

Additionally, if you are working with a lightweight aggregate that is not as strong as traditional concrete, your contractor may suggest increasing the thickness to compensate for this difference in strength. Finally, if you are using lightweight concrete in an area where there is a risk of water damage or frost heave, then your contractor may recommend increasing the thickness of the floor for added protection.

Conclusion

Lightweight concrete floors can provide a cost-effective and reliable solution for many indoor and outdoor applications. However, it is important to consider the recommended thickness of the floor before beginning any project. The required thickness of a lightweight concrete floor depends on several factors including the strength of the material, the type of aggregate used, and the load-bearing requirements of the project. Be sure to discuss these requirements with your contractor before beginning any project to ensure that your lightweight concrete floor will meet all your needs.