On account of this hardly obvious movement of the oak wood floor, considerations need being made through the setting up which is the explanation why it's most successfully taken care of by an authority floor coverings specialist. It is all up for you, which means become a well informed consumer.Observe what is obtainable and discover all you actually could regarding oak wood floors before you decide to settle on a purchase.

Images Related to Laying Engineered Wood Flooring Floating

Laying Engineered Wood Flooring Floating

/cdn.vox-cdn.com/uploads/chorus_asset/file/19493784/howto_tilefloor_04.jpg)

The benefits of having the wood floor of yours oiled is that it will keep for longer and will in addition delay the aging process so you are free to maintain the colour you initially bought. Engineered wood flooring is designed to be stable, and solid wood floors can just not compete in this particular area. An additional benefit would be that the factory finishes are usually much tougher than the polyurethane applied in the field.

How to Install an Engineered Hardwood Floating Floor with Finishing Tips

We personally do not look after prefinished flooring due to installation issues connected with it, thus our product usually requires site applied surface. Vinyl wood floors fills the void in between the most inexpensive hardwood flooring and the need for low-cost substitute flooring that's both cost effective, simple to install with rugged durability for established families with small domestic pets and children.

How to Install a Hardwood Floating Floor

All About Floating Wood Floors

Installing a Floating Wood Floor

What Is a Floating Floor? 50 Floor

Floating Floors Pros and Cons

/what-is-a-floating-floor-1821740-hero-00e6b7fe102e4fafa8ba3f926944bcb7.jpg)

How To Install Click Lock Engineered Hardwood Flooring

Which Tools Do You Need to Install Engineered Hardwood Floors

Which Method Should I Use to Install My Engineered Wood Floor

Glueless Click Installation for Floating Hardwood Floors

How to Install a Floating Engineered-Wood Floor Engineered wood

What is a Floating Floor: The Basics FlooringStores

Floating Floor vs. Nail Down Slaughterbeck Floors, Inc.

Related articles:

- Solid Wood Flooring White

- Bona Wood Floor Polish Gloss

- How Much Does Wood Flooring Cost To Install

- Wood Flooring For Outdoor Patio

- Wood Floor Texture Bump

- Rustic Gray Wood Flooring

- Wood Floor Queens

- Wood Floor Sleepers

- Cedar Wood Flooring Planks

- Teak Wood Flooring For Boats

Laying Engineered Wood Flooring Floating: A Comprehensive Guide

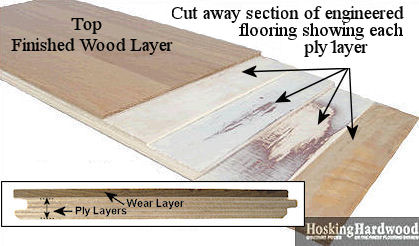

Engineered wood flooring offers a great alternative to solid wood flooring due to its affordability and durability. It is constructed with a layer of real wood on top of several layers of plywood or other composite material. This makes it more stable than solid wood, which can expand and contract with changes in temperature and humidity. Laying engineered wood flooring floating can be a great way to achieve a beautiful, long-lasting wood floor without the expense of installing hardwood.

What Is Floating Floor Installation?

Floating floor installation is a method used to install engineered wood floors without the need for nails or glue. Instead, the planks are connected together using tongue-and-groove joints and are then locked into place by an interlocking system. The planks are then laid on top of an underlayment material that acts as a cushion between the planks and the subfloor.

Advantages of Floating Floor Installation

There are several advantages to floating floor installation over other methods such as glue-down or nail-down installation. First, it is much easier to install than either glue-down or nail-down, so it is less labor intensive and often cheaper. Secondly, floating floors are more soundproof than either glue-down or nail-down floors, so they are better for those who live in apartments or condos where noise can be an issue. Lastly, floating floors are much easier to repair if there is ever damage since you can just pull up the damaged plank and replace it without having to repair any underlying damage.

Preparing for Installation

Before installing engineered wood floors floating, there are several steps that must be taken in order to ensure the best results. First, make sure that the subfloor is clean, dry, level and free of debris before laying down the underlayment material. It is also important to make sure that any cracks or holes in the subfloor are filled in order to prevent squeaking and movement in the floor. Once this has been done, the underlayment can be laid down and any necessary trimming can be done before laying down the planks.

Laying Down the Planks

Once all of the preparation is complete, it’s time to start laying down the planks! Begin by laying down your first row along one wall making sure that you leave enough space between each plank for expansion (usually about ¼ inch). The next row should be offset from the first row by at least 6 inches in order to create a staggered pattern. Continue laying down rows until you reach the opposite wall then cut your last row accordingly. Once all of the planks have been laid down it’s time to connect them together using their tongue-and-groove joints and secure them with an interlocking system.

Finishing Touches

Once all of the planks have been laid down it’s time to put on any finishing touches such as trim pieces around doorways or baseboards around walls. You may also want to add some transition strips between rooms where different types of flooring meet such as tile and hardwood. Finally, you may want to add some felt pads underneath furniture legs in order to prevent scratches in your new floor!

What tools are needed to install a floating engineered wood floor?

1. Tape measure2. Table saw

3. Jigsaw

4. Hammer

5. Nail gun

6. Pneumatic stapler

7. Chalk line

8. Safety glasses

9. Work gloves

10. Underlayment material

11. Spacers

12. Hardwood floor planks