Bamboo floors for kitchen are available in numerous options – the most famous of that are organic bamboo flooring as well as the carbonized bamboo flooring. It’s almost as difficult as oak and maple, and tougher than many of the regular hardwood flooring materials used in the normal homes. Quality bamboo flooring is usually made with bamboo that is harvested in the 7th year of its.

Here are Images about How To Glue Down Bamboo Flooring

How To Glue Down Bamboo Flooring

Bamboo isn’t actually a tree but a kind of grass. However, there are many explanations why some bamboo hardwood flooring is actually softer compared to others. Substantial export-quality bamboo flooring from a lot of the higher makers exhibits hardness, brightness, and freshness. Bamboo flooring is a unique and wonderful feature which has completely revolutionized the flooring community.

Glue Down Installation – Bamboo u0026 Hardwood Floor – Over Concrete

I am adding some of the popular brands to the names I have above. Ensure that the floor of yours is dry and clean before all of installations. As increasingly more homeowners go light green, bamboo begins to seep into their environmental interactions. This’s because the all-natural high sugar contained in the bamboo caramelizes, giving the bamboo this warm color.

Images Related to How To Glue Down Bamboo Flooring

Gluing Down Bamboo Flooring – Tips u0026 Tricks

Bamboo Flooring Installation, Installing Bamboo Floors, Wholesale

How to Install Bamboo Flooring (Tongue u0026 Groove – Over Underlay)

Which Method Should I Use to Install My Engineered Wood Floor

Nail vs Glue vs Float – Which Flooring Installation Method is Best?

Bamboo Flooring Cost 2024 Material and Installation Prices

Nail vs Glue vs Float – Which Flooring Installation Method is Best?

How to Install Uniclic Bamboo Flooring (over underlay)

Related articles:

- Bamboo Natural Flooring

- How To Clean Bamboo Floors With Vinegar

- Compressed Bamboo Flooring

- Scraped Bamboo Flooring

- Bamboo Flooring Glue Vs Floating

- Dark Mahogany Bamboo Flooring

- Natural Floors Brushed Spice Bamboo

- How To Glue Bamboo Flooring

- Bamboo Floor Repair Kit Scratches

- Bamboo Flooring Installation Problems

How To Glue Down Bamboo Flooring

Bamboo flooring has become increasingly popular in recent years due to its durability, sustainability, and aesthetic appeal. Gluing down bamboo flooring is a common installation method that ensures a secure and long-lasting bond between the bamboo planks and the subfloor. In this article, we will guide you through the step-by-step process of gluing down bamboo flooring, providing detailed instructions along with answers to frequently asked questions.

1. Preparing the Subfloor

Before you begin gluing down your bamboo flooring, it is crucial to ensure that the subfloor is clean, dry, level, and free from any debris or imperfections. Follow these steps to prepare the subfloor properly:

a) Clean the subfloor: Remove any dirt, dust, or residue from the subfloor using a broom or vacuum cleaner. Make sure there are no loose materials that could interfere with the adhesive bond.

b) Check for moisture: Bamboo flooring is sensitive to moisture, so it is essential to test the subfloor’s moisture levels before installation. Use a moisture meter to ensure that the subfloor’s moisture content is within an acceptable range (usually 12% or less). If necessary, take measures such as installing a moisture barrier or addressing any moisture issues before proceeding.

c) Level the subfloor: Inspect the subfloor for any uneven areas or low spots. Fill in gaps or holes with a suitable floor leveling compound and use a long straightedge to check for levelness. Sand down any high spots to achieve a smooth and even surface.

2. Acclimate the Bamboo Flooring

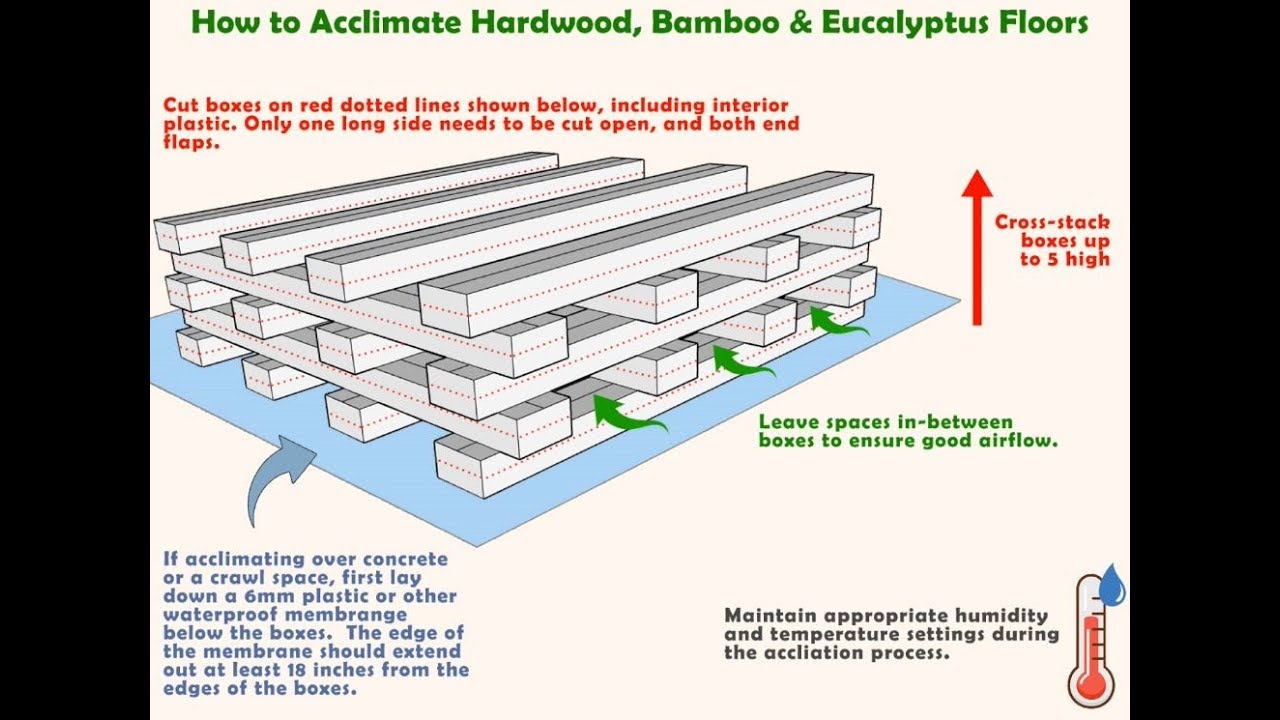

Proper acclimation of bamboo flooring is crucial to prevent any future problems such as warping or buckling. Follow these guidelines for acclimating your bamboo flooring:

a) Unbox and unwrap: Remove all packaging materials from the bamboo flooring boxes and unwrap each individual plank. Allow them to sit in the room where they will be installed for at least 72 hours. This acclimation period allows the planks to adjust to the temperature and humidity conditions of the space.

b) Maintain optimal conditions: During the acclimation period, maintain the room’s temperature and humidity levels within the range specified by the manufacturer. This typically ranges from 60°F to 80°F (15°C to 27°C) and a relative humidity of 40% to 60%.

c) Stack the planks: Stack the bamboo planks loosely, with spacers between each layer for proper air circulation. This stacking method ensures that all sides of the planks acclimate evenly.

3. Apply the Adhesive

Once your subfloor is prepared and the bamboo flooring has acclimated, it’s time to apply the adhesive and install the planks. Follow these steps for a successful glue-down installation:

a) Choose the right adhesive: Select a high-quality adhesive specifically designed for bamboo flooring installations. Consult with your flooring supplier or manufacturer for their recommended adhesive product.

b) Start in a corner: Begin in one corner of the room, preferably opposite from the main entrance. Apply a small amount of adhesive directly onto the subfloor using a trowel or notched spreader. Start with a manageable area that you can complete within 15-20 minutes.

c) Spread the adhesive: Use the flat side of your trowel to spread the adhesive evenly over an area that corresponds to one or two bamboo planks. Then, use the notched side of your Trowel to create grooves in the adhesive. This helps to ensure a strong bond between the subfloor and the bamboo planks.

d) Lay the planks: Carefully place the bamboo planks onto the adhesive, pressing them firmly into place. Use a rubber mallet or tapping block to gently tap the planks together if needed. Make sure to leave a small gap (usually around 1/4 inch) between the planks and any walls or obstacles to allow for expansion.

e) Continue the process: Repeat steps b-d, working your way across the room until all of the bamboo flooring is installed. Be sure to check periodically for any adhesive that may have squeezed up between the planks and clean it off before it dries.

4. Allow for proper drying time

After completing the glue-down installation, it’s important to allow sufficient drying time before subjecting the bamboo flooring to heavy foot traffic or furniture placement. Follow these guidelines:

a) Follow manufacturer recommendations: Consult with your flooring manufacturer for their recommended drying time. This can vary depending on factors such as humidity levels and adhesive used.

b) Avoid excessive moisture: During the drying period, avoid excessive moisture on the newly installed bamboo flooring. This includes avoiding wet mopping or any spills that could seep into the seams between planks.

c) Protect the floor: Place protective coverings over the newly installed bamboo flooring to prevent damage from heavy objects or furniture being moved across it.

By following these steps, you can ensure a successful glue-down installation of your bamboo flooring. It is important to carefully read and follow all manufacturer instructions to ensure proper installation and avoid any potential issues or damage. Additionally, it is recommended to hire a professional installer or consult with a flooring specialist for guidance and assistance during the installation process. They can provide valuable expertise and ensure that the bamboo flooring is installed correctly and efficiently. The main entrance. Apply a small amount of adhesive directly onto the subfloor using a trowel or notched spreader. Start with a manageable area that you can complete within 15-20 minutes. Spread the adhesive evenly over an area that corresponds to one or two bamboo planks using the flat side of the trowel. Use the notched side of the trowel to create grooves in the adhesive for a strong bond with the subfloor. Carefully place the bamboo planks onto the adhesive, pressing them firmly into place. Use a rubber mallet or tapping block to gently tap the planks together if needed. Leave a small gap between the planks and walls or obstacles for expansion. Repeat these steps across the room until all bamboo flooring is installed, checking for and cleaning off any excess adhesive before it dries. Allow sufficient drying time following manufacturer recommendations, avoiding excessive moisture and protecting the floor from heavy objects or furniture during this period. It is important to read and follow all manufacturer instructions and consider hiring a professional installer for guidance and assistance.