They are highly-resistant to oil, chemicals, water, and physical impact from pedestrian traffic and physical lots. And, in case you've painted floors, the finest option for you is removing the old paint before making use of any form of epoxy. Furthermore, the self-leveling feature of epoxy compound gives consistent surface in spite of flooring with splits as well as bumps.

Here are Images about Flex Epoxy Flooring

Flex Epoxy Flooring

They're created to conquer every obstacle ranging from probably the toughest stains which are tough to get rid of as well as to endure probably the toughest environmental situations. You just clean and prep your floor and then start applying the brand new epoxy flooring surface area with a roller. This makes the floor look neater as well as cleaner. The surface is actually drinking water and stain resistant.

Flex Epoxy Flooring Inc added a – Flex Epoxy Flooring Inc

Epoxy adheres very well to surfaces made from concrete, metal, tiles, wood, and other things. Epoxy provides floors a glossy, glassy appearance which can make the entire region vibrantly stand out in terms of high end visual appearance and appeal. It need to have an epoxy resin, a clear or amber viscous liquid. Your floors will usually be in great shape. Anti-slip flecks are actually made of acrylic and offer a decorative touch to an epoxy floor.

Images Related to Flex Epoxy Flooring

Flex Epoxy Flooring Solution for California Dispensary – Westcoat

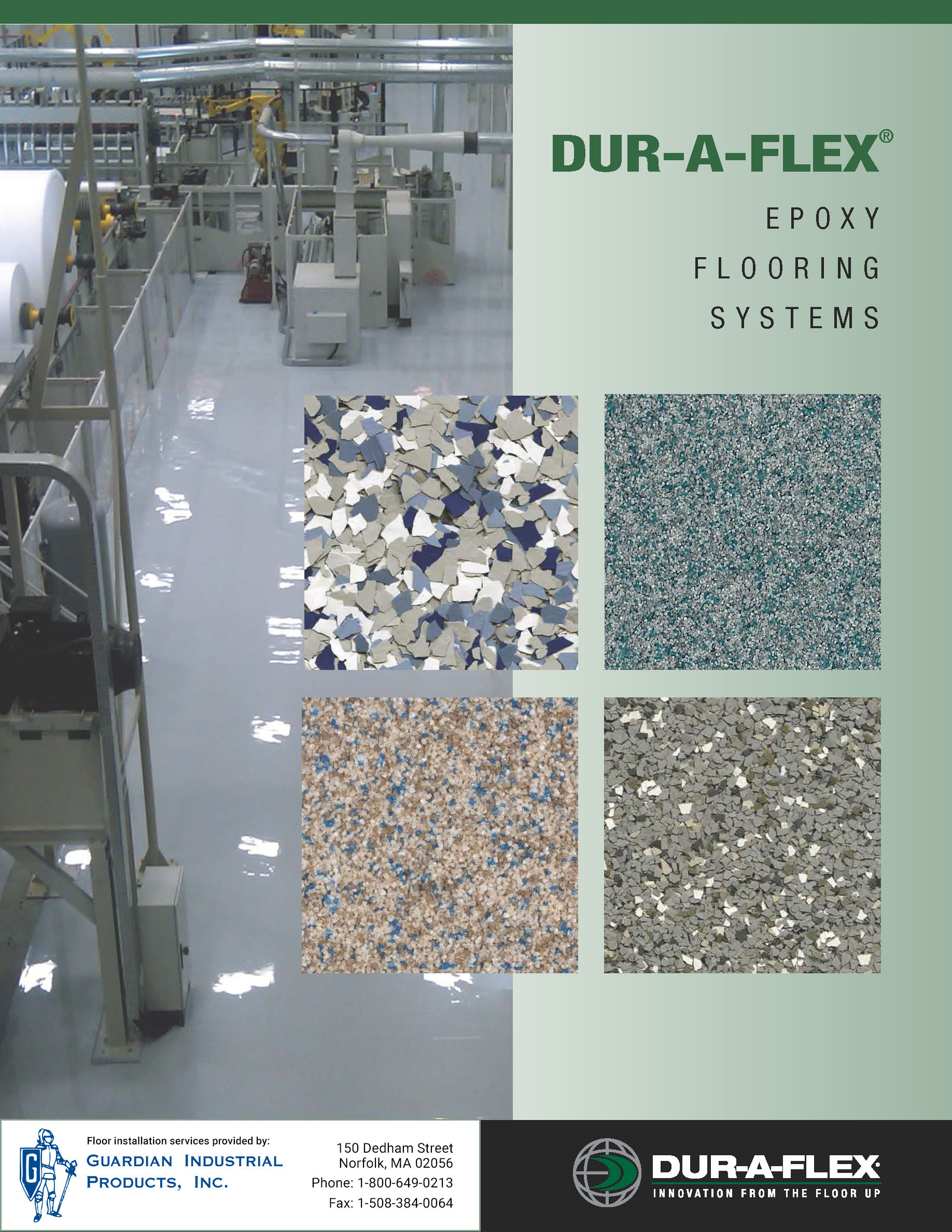

Dur-A-Chip Vinyl Chip Flooring Dur-A-Flex

Epoxy Vinyl Chip Industrial Flooring Systems -Surface Solutions, Inc.

Dur-a-Flex Epoxy Systems – Flooring Concepts Inc.

Flex Epoxy Flooring Solution for California Dispensary – Westcoat

Flex Epoxy Flooring Inc – Home Facebook

Dur-A-Crete – Dur-A-Flex

Metallic Epoxy Flooring System – Dur-a-Flex Flooring contractor

Industrial Flooring Colors and Materials ME NH CT RI

Flex-Coat – 98% Solids Polyurea – Seal-Krete High Performance Coatings

Flex Epoxy System – Westcoat Specialty Coating Systems

Epoxy Flooring Installation, Flooring Contractor Buffalo, NY

Related articles:

- Metallic Epoxy Floor Designs

- Epoxy Flooring Contractors

- Epoxy Floor Coating Material

- Epoxy Floor Coating With Flakes

- Epoxy Floor Finishes Concrete

- Epoxy Flooring Design

- DIY Epoxy Flooring Systems

- Epoxy Floor Coating Designs

- Epoxy Flooring Basement

- Artistic Epoxy Flooring

Flex epoxy flooring is a revolutionary type of flooring material that has been gaining popularity in both residential and commercial spaces. It is an attractive, durable, and easy to maintain option for floors that require a high level of protection. Not only does flex epoxy flooring offer exceptional protection against wear, it also has excellent resistance to chemicals, moisture, and extreme temperatures. This article will provide an introduction to flex epoxy flooring, its benefits, and application.

What is Flex Epoxy Flooring?

Flex epoxy flooring is a two-component system made of a resin and hardener that are mixed together and applied to the floor. Flex epoxy is a hybrid floor system, combining the best features of epoxies and polyurethanes. It offers unparalleled protection, flexibility, and durability compared to traditional floor coatings.

Benefits of Flex Epoxy Flooring

Flex epoxy offers superior resistance to wear, chemicals, and extreme temperatures. It forms a seamless bond with the existing concrete surface which eliminates dirt traps, water infiltration, and mold growth. Its non-porous surface also makes it easy to clean and maintain. Additionally, flex epoxy has superior resistance to abrasion, impact, thermal shock, heavy traffic, and UV light exposure. Furthermore, it provides an aesthetically pleasing finish that can be customized with decorative flakes or chips to match any color scheme or design.

Application of Flex Epoxy Flooring

Flex epoxy floors can be installed in both residential and commercial areas such as garages, warehouses, workshops, auto shops, factories and more. The installation process involves preparation of the concrete surface which includes cleaning, etching and priming the area. After the surface is properly prepared and all the necessary materials are gathered the installation process can begin. The installation process typically involves applying multiple coats of flex epoxy followed by a clear topcoat for additional protection.

FAQs

Q: How long does flex epoxy flooring last?

A: Flex epoxy flooring can last up to 10 years with proper maintenance.

Q: Is flex epoxy flooring slip resistant?

A: Yes, flex epoxy is slip resistant when installed with a textured finish or anti-slip additives.

Q: Does flex epoxy require special maintenance?

A: No special maintenance is required for flex epoxy floors; they can be cleaned using warm water and a mild detergent.

Conclusion

Flex epoxy flooring is an excellent choice for residential and commercial spaces that require superior protection from wear and tear as well as chemical exposure. It provides an attractive finish that can be customized with decorative chips or flakes to match any color scheme or design. Additionally, it is easy to clean and maintain requiring only warm water and mild detergent for regular cleaning. If you are looking for an attractive yet durable floor solution then flex epoxy may be the perfect choice for you.