But, seamless epoxy flooring gives you many advantages in a cost highly effective way. Concrete is porous which enables it to soak up dirt, salt, chemicals and oils, making it tough to wash the concrete floors correctly. It remains to end up being probably the most sought after coatings systems that meet any type of coatings application demands. There's no difficulties with concrete dust, and also cleaning is also easy.

Here are Images about Euclid Epoxy Floor Coating

Euclid Epoxy Floor Coating

Manufacturing epoxy floors covering merchandise is often the top choice for floor maintenance and repair. It is then terrific for places where heavy equipment and foot traffic comes into contact with the floors. Epoxy flooring coating provides a sanitary and skid-proof surface sometimes when damp. It offers strong adhesion, exceptional chemic resistance and toughness.

Euclid Chemical Launches New Solvent-Free Epoxy Coatings for

Aside from the durability of epoxy flooring, it is in a position to withstand damage that is actually brought on by various chemic solutions. No matter whether you want the garage of yours to seem even more enticing or maybe your studio to appear more inviting, you're likely to find the color you would like to make some floor stand out or even delicately blend in with the rest of the decor.

Images Related to Euclid Epoxy Floor Coating

High Performance Floor Coatings

UAC Epoxy Flooring Euclid – Euclid Epoxy Floor

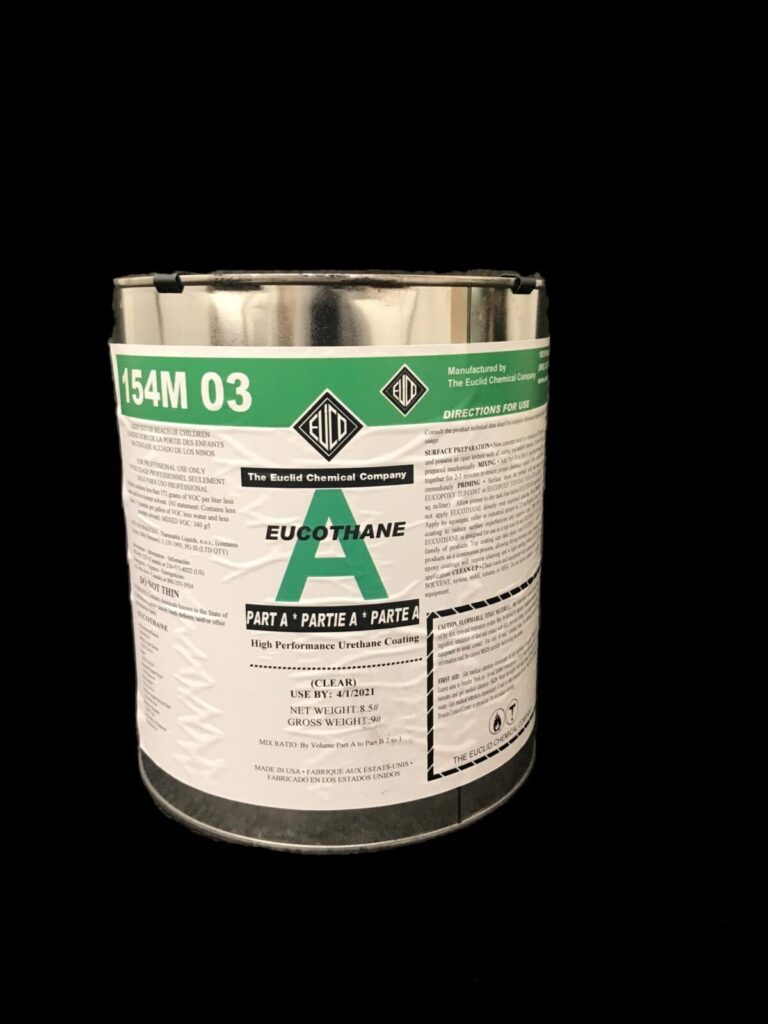

Euclid Eucothane 3G : Polyurethane Coating for Concrete

Epoxy Flooring Euclid Product

The Dural Aquatight 100 Plus Solvent-Free Epoxy Coating From: The

UAC Epoxy Flooring Euclid – Euclid Epoxy Floor

E5015 Epoxy Primer WB Coating Concrete Wood Masonry 20 Colors

UAC Epoxy Flooring Euclid – Euclid Epoxy Floor

Euclid Chemical

The Dural 50 LM FS Solvent-Free Epoxy Coating From: The Euclid

Euco 700 Industrial Joint Filler, 2 gallon unit

Euclid DURALTEX 1705/1707 (100% Epoxy) Coatings Hub

Related articles:

- Metallic Epoxy Floor Designs

- Epoxy Flooring Contractors

- Epoxy Floor Coating Material

- Epoxy Floor Coating With Flakes

- Epoxy Floor Finishes Concrete

- Epoxy Flooring Design

- DIY Epoxy Flooring Systems

- Epoxy Floor Coating Designs

- Epoxy Flooring Basement

- Artistic Epoxy Flooring

Euclid Epoxy Floor Coating: Enhanced Durability and Aesthetic Appeal

When it comes to flooring solutions, durability and aesthetic appeal are two essential factors to consider. One popular option that fulfills both these requirements is Euclid epoxy floor coating. This innovative flooring solution has gained significant popularity in recent years due to its exceptional durability, versatility, and aesthetic possibilities. In this article, we will delve into the various aspects of Euclid epoxy floor coating, exploring its benefits, applications, installation process, and maintenance requirements.

I. Introduction to Euclid Epoxy Floor Coating

Euclid epoxy floor coating is a high-performance flooring system that combines epoxy resins and hardeners to form a strong, chemical-resistant surface. It is typically applied as a multi-layered system consisting of a primer, base coat, colored quartz or decorative flakes (if desired), and a clear topcoat. This seamless flooring solution provides a smooth, glossy finish that not only enhances the aesthetics of any space but also offers unmatched durability.

A. Benefits of Euclid Epoxy Floor Coating

Euclid epoxy floor coating offers numerous benefits that make it an excellent choice for various commercial, industrial, and residential applications.

1. Durability: One of the primary advantages of Euclid epoxy floor coating is its exceptional durability. It can withstand heavy foot traffic, impacts from dropped objects, and even chemical spills without showing signs of wear or damage.

2. Chemical Resistance: Euclid epoxy floor coating is highly resistant to various chemicals such as oils, solvents, acids, alkalis, and cleaners. This makes it an ideal choice for industries that deal with potentially corrosive substances.

3. Easy Maintenance: The seamless nature of Euclid epoxy floor coating eliminates the presence of grout lines or seams where dirt and bacteria can accumulate. This makes cleaning a breeze – simply sweep or mop the surface regularly to maintain its pristine appearance.

4. Aesthetic Versatility: Euclid epoxy floor coating offers a wide range of aesthetic possibilities. With options like colored quartz, decorative flakes, and custom designs, you can create a unique flooring solution that complements the overall design scheme of your space.

B. Applications of Euclid Epoxy Floor Coating

Euclid epoxy floor coating is suitable for a variety of applications, ranging from industrial warehouses to residential garages. Here are some common areas where this flooring system excels:

1. Industrial Facilities: Due to its exceptional durability and chemical resistance, Euclid epoxy floor coating is often used in warehouses, manufacturing plants, and other industrial facilities. It can withstand heavy machinery, forklift traffic, and chemical spills without deteriorating or becoming damaged.

2. Commercial Spaces: Retail stores, restaurants, showrooms, and other commercial spaces benefit greatly from the aesthetic versatility of Euclid epoxy floor coating. Its seamless finish and glossy appearance create an inviting atmosphere for customers while withstanding the demands of a high-traffic environment.

3. Residential Garages: Euclid epoxy floor coating is an ideal choice for residential garages due to its ability to resist oil stains, tire marks, and other common garage hazards. Its easy maintenance requirements make it a practical and visually appealing option for homeowners.

4. Healthcare Facilities: The chemical resistance of Euclid epoxy floor coating makes it suitable for healthcare facilities such as hospitals, clinics, and laboratories. It can withstand frequent cleaning with disinfectants without deteriorating or harboring bacteria.

C. Installation Process of Euclid Epoxy Floor Coating

The installation process of Euclid epoxy floor coating involves the following steps:

1. Surface Preparation: The first step is to prepare the surface by removing any existing coatings, dirt, grease, or debris. This can be done through methods such as grinding, shot blasting, or chemical cleaning.

2. Patching and Repairs: Any cracks, holes, or damaged areas in the concrete substrate are repaired using appropriate patching materials. This ensures a smooth and even surface for the epoxy coating.

3. Primer Application: A primer is applied to the prepared surface to enhance adhesion between the concrete and the epoxy coating. It helps create a strong bond and prevents any potential issues such as delamination or peeling.

4. Epoxy Coating Application: The Euclid epoxy floor coating is mixed according to the manufacturer’s instructions and applied to the primed surface using a roller or squeegee. Multiple coats may be required depending on the desired thickness and durability.

5. Optional Decorative Elements: If desired, decorative elements like colored quartz or decorative flakes can be broadcasted onto the wet epoxy surface to create a customized design.

6. Top Coat Application: Once the base coat has cured, a clear top coat is applied to provide additional protection and enhance the glossiness of the floor. This top coat also helps improve chemical resistance and durability.

7. Curing and Drying: The epoxy coating requires a specific curing time before it can be subjected to foot traffic or other activities. This curing time varies depending on factors such as temperature and humidity.

Overall, Euclid epoxy floor coating offers numerous advantages and applications across various industries. Its durability, chemical resistance, easy maintenance, and aesthetic versatility make it a popular choice for both commercial and residential spaces. Euclid epoxy floor coating is a popular choice for various industries due to its durability, chemical resistance, easy maintenance, and aesthetic versatility. It can be applied in a variety of settings, including industrial facilities, commercial spaces, residential garages, and healthcare facilities.

In industrial facilities, Euclid epoxy floor coating provides a durable and long-lasting solution that can withstand heavy machinery, high foot traffic, and potential spills or chemicals. It offers excellent resistance to abrasion, impact, and wear, making it suitable for manufacturing plants, warehouses, and distribution centers.

Commercial spaces such as retail stores, restaurants, and offices can benefit from Euclid epoxy floor coating as well. Its seamless and smooth surface is visually appealing and easy to clean. It can also withstand the daily wear and tear of foot traffic, furniture movement, and potential spills.

Residential garages also benefit from Euclid epoxy floor coating. Its resistance to tire marks and other common garage hazards makes it a practical choice for homeowners. Additionally, its easy maintenance requirements make it an attractive option for keeping the garage clean and visually appealing.

In healthcare facilities such as hospitals, clinics, and laboratories, the chemical resistance of Euclid epoxy floor coating makes it suitable. It can withstand frequent cleaning with disinfectants without deteriorating or harboring bacteria. This ensures a hygienic environment that is essential in healthcare settings.

The installation process of Euclid epoxy floor coating involves several steps. First, the surface needs to be prepared by removing any existing coatings, dirt, grease, or debris. This can be done through methods such as grinding, shot blasting, or chemical cleaning.

Next, any cracks, holes, or damaged areas in the concrete substrate are repaired using appropriate patching materials. This ensures a smooth and even surface for the epoxy coating.

A primer is then applied to enhance adhesion between the concrete and the epoxy coating. This helps create a strong bond and prevents issues such as delamination or peeling.

The Euclid epoxy floor coating is mixed according to the manufacturer’s instructions and applied to the primed surface using a roller or squeegee. Multiple coats may be required depending on the desired thickness and durability.

If desired, decorative elements like colored quartz or decorative flakes can be broadcasted onto the wet epoxy surface to create a customized design.

Once the base coat has cured, a clear top coat is applied to provide additional protection and enhance the glossiness of the floor. This top coat also improves chemical resistance and durability.

The epoxy coating requires a specific curing time before it can be subjected to foot traffic or other activities. This curing time varies depending on factors such as temperature and humidity.

Overall, Euclid epoxy floor coating offers numerous advantages and applications across various industries. Its durability, chemical resistance, easy maintenance, and aesthetic versatility make it a popular choice for both commercial and residential spaces.