They're not toxic when dried out and hence, could be put to use safely even in residential assignments as well as kids play parts. In addition, epoxy floor coatings are durable enough to resist abrasives, acid, and chemicals that could be present in the factory of yours. Epoxy floors are extremely long lasting (anywhere between 15 to 20 years) and hence generate good returns on the expense made.

Here are Images about Epoxy Floor Thickness

Epoxy Floor Thickness

In a factory created where flooring is subject to a lot of wear and tear, option of the right flooring is essential, since it's an element of the initial investment and it is usually dispersed throughout a huge spot. You ought to absolutely consider an epoxy flooring coating when you are considering changing your sports surfaces.

How Thick Should an Epoxy Floor Coating Be? – Florock

Epoxy floors coatings are inexpensive compared with some other floor coatings. While concrete is seen as practically indestructible, it's not impervious to specific damage types, including cosmetic, including scuffing, staining as well as cracking. Nonetheless, if the area affected is significant large, color mismatch will be apparent. Hence, it is not designed for epoxy covering.

Images Related to Epoxy Floor Thickness

Industrial Floorings FAQs PSC Flooring Ltd. Epoxy Flooring

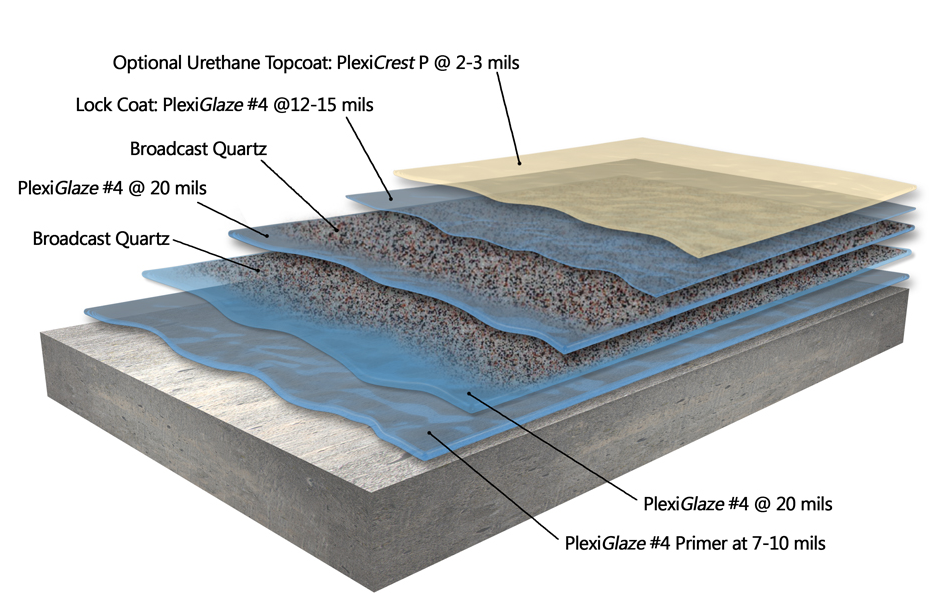

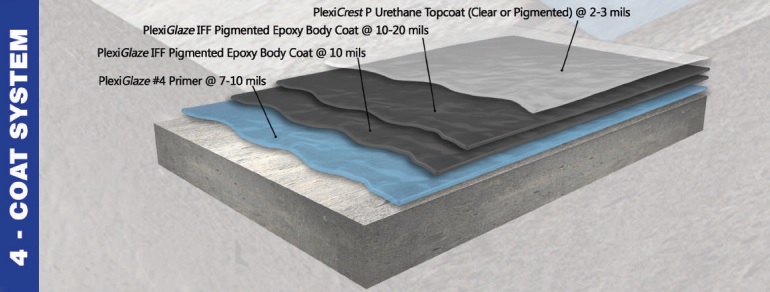

Unlocking the Mystery of Mils u2013 Plexi-Chemie, Inc.

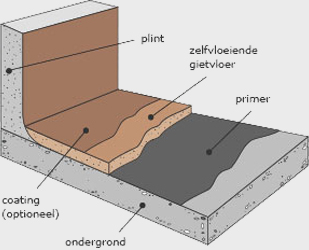

Construction of industrial self-leveling epoxy flooring – ISOMAT

Epoxy Terrazzo National Terrazzo and Mosaic Association

Epoxy Flooring Orlando: What is Epoxy Flooring? Our Team Explains

GARAGE FLOOR EPOXY PAINTING, GARAGE FLOOR EPOXY FLOORING, FLAKE

Epoxy Flooring Systems wsmepoxyfloors

Construction of industrial self-leveling epoxy flooring – ISOMAT

How thick is a garage floor mat (really) – GarageFlooringLLC.com

Modified epoxy floor? All the benefits of PU and Epoxy – HIM

How Thick Should My Epoxy Flooring Be?

The Right Choice: Plexi-Chemie Offers Two, Three and Four Coat

Related articles:

- DIY Epoxy Floor Garage

- Epoxy Flooring Systems Grand Forks

- Epoxy Flooring Nashville Tn

- Metallic Epoxy Flooring In Bangalore

- Affordable Epoxy Flooring Installers

- Epoxy Floor Paint Quality

- Epoxy Floor Paint Philippines

- Epoxy Flooring Windsor Ontario

- Epoxy Flooring Rockford Il

- Epoxy Floor Nj

Epoxy Floor Thickness: The Key to a Durable and Long-lasting Flooring Solution

When it comes to choosing the right flooring solution for industrial, commercial, or residential spaces, epoxy floors have gained immense popularity in recent years. With their durability, versatility, and aesthetic appeal, epoxy floors have become a preferred choice for many property owners. However, one crucial aspect that often gets overlooked is the thickness of the epoxy floor coating. In this article, we will delve into the importance of epoxy floor thickness and explore its various implications.

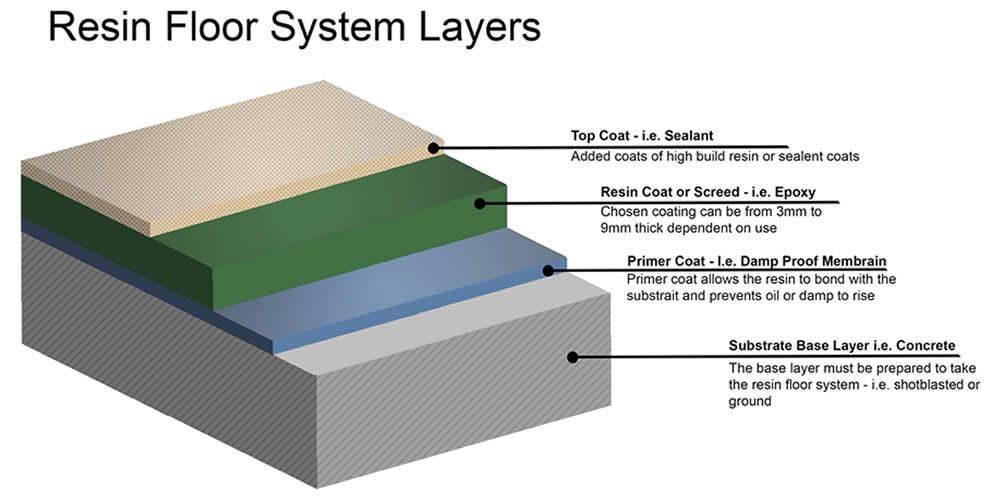

1. Understanding Epoxy Floor Thickness

The thickness of an epoxy floor refers to the depth of the epoxy coating applied onto the substrate. It plays a vital role in determining the overall performance and longevity of the flooring system. Epoxy floors are typically applied in multiple layers, with each layer contributing to the final thickness. The thickness can vary depending on the specific requirements of the space and the type of traffic it will encounter.

2. Importance of Adequate Epoxy Floor Thickness

Having an adequate epoxy floor thickness is crucial for several reasons:

a) Durability: A thicker epoxy coating provides enhanced durability and resistance to wear and tear. It ensures that the flooring can withstand heavy foot traffic, vehicle movement, and other impacts without getting damaged easily.

b) Chemical Resistance: Epoxy floors are known for their exceptional chemical resistance properties. A thicker coating enhances this resistance, making it more suitable for areas exposed to harsh chemicals or spills.

c) Impact Resistance: Thicker epoxy coatings offer superior impact resistance compared to thinner ones. This is particularly important in environments where heavy machinery or equipment is used, as it helps prevent damage caused by dropped tools or accidental impacts.

d) Moisture Barrier: Epoxy floors can act as a moisture barrier when applied correctly. A thicker coating provides better protection against moisture intrusion, preventing issues such as mold growth, water damage, or substrate deterioration.

e) Longevity: The lifespan of an epoxy floor is directly influenced by its thickness. A thicker coating can significantly extend the lifespan of the flooring system, reducing the need for frequent repairs or replacements.

3. Factors Influencing Epoxy Floor Thickness

Several factors need to be considered when determining the appropriate epoxy floor thickness for a specific application:

a) Type of Space: The type of space and its purpose play a crucial role in deciding the epoxy floor thickness. For instance, industrial settings with heavy machinery and high foot traffic will require a thicker coating compared to a residential garage.

b) Traffic Load: The expected traffic load on the flooring system is an essential consideration. Areas with heavy vehicular traffic or frequent movement of heavy machinery will require a thicker epoxy coating to withstand the stress and prevent premature wear.

c) Chemical Exposure: If the space is prone to chemical spills or exposure, selecting a thicker epoxy coating becomes imperative. This ensures that the flooring can withstand potential chemical damage without deteriorating.

d) Substrate Condition: The condition of the substrate also affects the required thickness. Uneven or damaged substrates may necessitate additional layers to ensure a smooth and level surface.

4. Determining the Right Epoxy Floor Thickness

Determining the ideal epoxy floor thickness involves careful evaluation of various factors and considerations. Here are some steps you can follow to determine the appropriate thickness:

a) Consultation with Professionals: Seek advice from experienced professionals who specialize in epoxy flooring. Their expertise will help in assessing your specific requirements and recommending suitable options.

b) Understanding Industry Standards : Familiarize yourself with industry standards and guidelines for epoxy floor thickness. These standards can provide a baseline for determining the appropriate thickness for your specific application.

c) Assessing Space and Usage: Evaluate the type of space, its purpose, and the expected traffic load. Consider factors such as heavy machinery usage, foot traffic, and potential chemical exposure. This will help determine the level of protection and durability required.

d) Consulting Product Data Sheets: Review product data sheets provided by epoxy manufacturers. These sheets often provide recommendations for the ideal thickness based on the specific product’s properties and intended use.

e) Conducting Site Inspections: Perform thorough site inspections to assess the condition of the substrate. Identify any uneven or damaged areas that may require additional layers of epoxy to ensure a smooth and level surface.

f) Considering Budget Constraints: Take into account budget constraints when determining the epoxy floor thickness. Thicker coatings may offer enhanced properties but can also be more expensive. Strike a balance between desired performance and cost-effectiveness.

g) Testing and Sampling: Consider conducting tests or obtaining samples to evaluate the performance of different epoxy thicknesses in your specific environment. This can help validate your decision before committing to a full installation.

By carefully considering these factors and following these steps, you can determine the appropriate epoxy floor thickness that best meets your needs and ensures long-lasting durability. 1. Evaluate the specific requirements and potential chemical exposure of the space.

2. Seek advice from experienced professionals who specialize in epoxy flooring.

3. Familiarize yourself with industry standards and guidelines for epoxy floor thickness.

4. Assess the condition of the substrate, identifying any uneven or damaged areas.

5. Review product data sheets provided by epoxy manufacturers for recommended thicknesses.

6. Consider budget constraints when determining the epoxy floor thickness.

7. Conduct tests or obtain samples to evaluate different epoxy thicknesses in your specific environment.

8. Make a decision that strikes a balance between desired performance and cost-effectiveness.

9. Ensure long-lasting durability by following these steps and considering all relevant factors. In summary, the steps to determine the appropriate epoxy floor thickness include:

1. Evaluate the specific requirements and potential chemical exposure of the space.

2. Seek advice from experienced professionals who specialize in epoxy flooring.

3. Familiarize yourself with industry standards and guidelines for epoxy floor thickness.

4. Assess the condition of the substrate, identifying any uneven or damaged areas.

5. Review product data sheets provided by epoxy manufacturers for recommended thicknesses.

6. Consider budget constraints when determining the epoxy floor thickness.

7. Conduct tests or obtain samples to evaluate different epoxy thicknesses in your specific environment.

8. Make a decision that strikes a balance between desired performance and cost-effectiveness.

9. Ensure long-lasting durability by following these steps and considering all relevant factors.