To have an epoxy coating applied to the floors of theirs a household can invest in a system from home improvement stores. Epoxy flooring is an extremely long-lasting flooring surface area for most shops & garages. They are okay to be used on all categories of surfaces including concrete along with other floor materials and frequently, even on damaged floors.

Here are Images about Epoxy Floor Patch

Epoxy Floor Patch

It is a versatile coating that can suit both the color of yours as well as thickness must have. that is why before buying it, see to it that you know the way to do it or much better one should ask for guidance. One of the main benefits of choosing epoxy flooring is that most tasks can be done by you.

Epoxy Floor Patch (AP-100) – USANNEX

This option revolves around the facts which epoxy flooring is extremely durable, involves minimum maintenance and is eco friendly. This tends to diminish any wastage and help save you dollars. The professionals understand every single aspect of the surfacing plus they could utilize the most up technology for using the epoxy coloring over your floors.

Images Related to Epoxy Floor Patch

Self Leveling Epoxy Floor Patch Clear

Epoxy Concrete Patch Repair Damaged Plant Floors u0026 Expansion Joints

Watco Flowpatch – self levelling concrete patch repair

Rust-Oleum 24 oz. Concrete Patch and Repair Kit 301012 – The Home Depot

Repairing Epoxy Floor-Atlas Coating-Sydney

Epoxy Floor Patch FULL KIT

Chips and Cracking: How to Repair Your Epoxy Floors – Epoxy Floors LLC

Concrete Floor Crack u0026 Joint Repair Services in Michigan

FAST SET EPOXY PATCH KIT, 1 u0026 2 GAL

Fast-Patch Concrete Patching Kit

epoxy-floor-patch-1 u003e MSC Floors

Easily Repair Your Pitted or Spalled Garage Floor All Garage Floors

Related articles:

- Metallic Epoxy Floor Designs

- Epoxy Flooring Contractors

- Epoxy Floor Coating Material

- Epoxy Floor Coating With Flakes

- Epoxy Floor Finishes Concrete

- Epoxy Flooring Design

- DIY Epoxy Flooring Systems

- Epoxy Floor Coating Designs

- Epoxy Flooring Basement

- Artistic Epoxy Flooring

Epoxy Floor Patch: A Comprehensive Guide to Repairing and Restoring Your Floors

Introduction:

When it comes to maintaining the beauty and functionality of your flooring, it’s essential to address any damages or imperfections promptly. One effective solution for repairing and restoring damaged floors is using an epoxy floor patch. This versatile material not only fixes cracks, holes, and other surface irregularities but also provides a durable and long-lasting finish. In this comprehensive guide, we will delve into the world of epoxy floor patches, exploring their benefits, application techniques, FAQs, and more.

I. Understanding Epoxy Floor Patch:

Epoxy floor patch is a specialized compound designed to repair and restore damaged concrete floors. It is composed of an epoxy resin and a hardener that are mixed together to form a strong adhesive substance. This mixture creates a bond that effectively fills in cracks, divots, and other types of surface imperfections. Once applied, the epoxy floor patch dries to create a smooth and durable surface that can withstand heavy foot traffic and other stresses.

II. Benefits of Using Epoxy Floor Patch:

1. Versatility: Epoxy floor patches can be used on various types of flooring surfaces, including concrete, wood, tile, and even metal. This versatility makes them an excellent choice for both residential and commercial applications.

2. Durability: The epoxy resin used in floor patches creates a robust and resilient surface that can withstand heavy wear and tear. It forms a protective barrier that helps prevent further damage to the flooring.

3. Seamless Finish: When properly applied, an epoxy floor patch seamlessly integrates with the existing flooring surface, creating a uniform appearance that enhances the overall aesthetics of the space.

4. Cost-Effective Solution: Repairing damaged floors can be expensive, especially if replacement is necessary. Epoxy floor patches offer a cost-effective alternative by providing a reliable method for fixing minor issues without the need for extensive repairs or replacements.

5. Resistance to Chemicals and Stains: Epoxy floor patches are highly resistant to chemicals, oils, solvents, and stains. This makes them an ideal choice for areas where spills or exposure to harsh substances are common, such as garages, workshops, and industrial facilities.

III. Application Techniques:

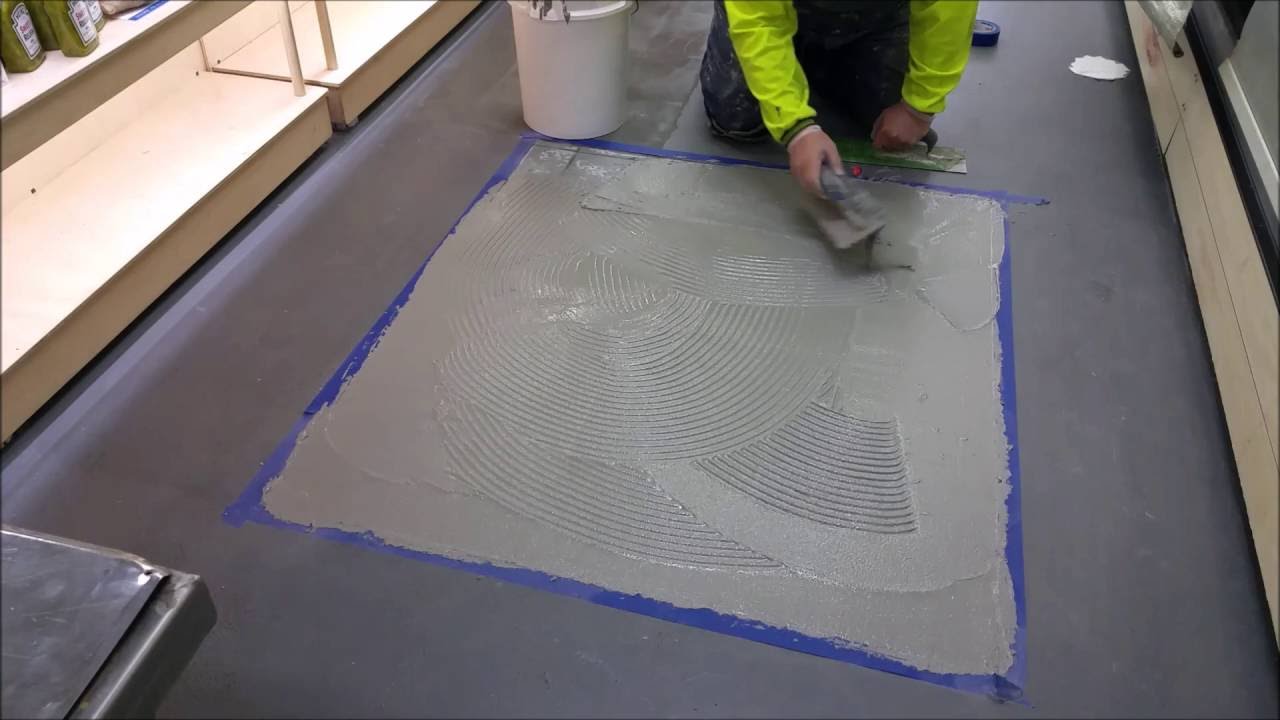

1. Surface Preparation: Before applying an epoxy floor patch, it is crucial to prepare the surface properly. Start by cleaning the damaged area thoroughly, removing any loose debris, dust, or contaminants. For better adhesion, it may be necessary to roughen the surface using a grinder or a diamond cup wheel.

2. Mixing the Epoxy: Follow the manufacturer’s instructions for mixing the epoxy resin and hardener. It is important to achieve a thorough and consistent blend to ensure optimal performance.

3. Applying the Patch: Using a trowel or putty knife, carefully apply the epoxy floor patch to the damaged area. Ensure that it is spread evenly and fills all cracks and holes completely. If necessary, multiple layers can be applied for deeper repairs.

4. Smoothing and Finishing: Once the epoxy floor patch is applied, use a metal trowel or a squeegee to smooth out the surface and remove any excess material. Pay close attention to achieving a level finish that seamlessly merges with the surrounding flooring.

5. Curing Time: Allow the epoxy floor patch to cure according to the manufacturer’s instructions. This typically ranges from a few hours to several days depending on factors such as temperature and Humidity. During this time, it is important to avoid walking on or placing heavy objects on the repaired area to prevent damage to the freshly applied patch.

6. Final Touches: After the epoxy floor patch has fully cured, it can be further enhanced by applying a protective topcoat or sealer. This will provide additional durability and resistance to stains, chemicals, and abrasion.

IV. Maintenance and Care:

1. Regular Cleaning: To maintain the appearance and performance of an epoxy floor patch, it is important to regularly clean the surface. Sweep or vacuum the area to remove loose dirt and debris, and mop with a mild detergent solution as needed.

2. Avoid Harsh Chemicals: While epoxy floor patches are highly resistant to chemicals, it is still advisable to avoid using harsh cleaning agents that may degrade or discolor the surface. Stick to mild cleaners specifically designed for use on epoxy floors.

3. Preventive Measures: To minimize the risk of damage, it is recommended to use mats or rugs in high-traffic areas or places prone to spills. Additionally, avoid dragging heavy objects across the floor to prevent scratches or gouges.

4. Periodic Maintenance: Over time, an epoxy floor patch may experience wear and minor damage. It is important to address these issues promptly by applying touch-up patches or reapplying a protective topcoat as needed.

5. Professional Assistance: For more extensive repairs or if you are unsure about how to properly maintain your epoxy floor patch, it is advisable to seek professional assistance. They can provide expert advice and perform any necessary repairs or maintenance tasks efficiently and effectively. They may also offer additional services such as deep cleaning, polishing, or resealing to keep your epoxy floor patch looking and performing its best. Remember to follow any specific maintenance guidelines provided by the manufacturer of your epoxy floor patch to ensure optimal results and longevity. Overall, maintaining and caring for an epoxy floor patch involves regular cleaning, avoiding harsh chemicals, taking preventive measures, performing periodic maintenance, and seeking professional assistance when needed. By following these guidelines, you can keep your epoxy floor patch looking and performing its best for years to come.