They're highly resistant to physical impact, water, chemicals, and oil from physical plenty and pedestrian traffic. And, if you've painted floors, the best choice for you is removing the old paint before using any sort of epoxy. Additionally, the self leveling feature of epoxy combination offers consistent surface in spite of flooring with splits and bumps.

Here are Images about Epoxy Floor Paint Problems

Epoxy Floor Paint Problems

Even if you spill a number of viscous solution that is a chemical agent, you are going to be in the position to get rid of the solution in a jiffy. Epoxy is made out of a combination of liquid hardening chemicals as well as liquid polymer resin. It is going to make your dull and sedentary concrete floor look stylish and damage free. Epoxy flooring comes with powerful adhesive characteristics that make it durable, dirt & dust resistant and inflammable.

Why Garage Floor Epoxy Peels Up and How to Prevent It All Garage

With good area preparation, manufacturing epoxy floor coating applications work with a high possibility of success. It lays nicely on countless kinds of surfaces like metal, concrete, tile and wood and is unwilling to most harsh chemicals making for a durable and some style and long-lasting surface might possibly be extra to the epoxy for a little bit of flare. Epoxy concrete paints are highly durable and can withstand pressure that is high.

Images Related to Epoxy Floor Paint Problems

How to Fix a Peeling Epoxy Floor – LearnCoatings

Why Garage Floor Epoxy Peels Up and How to Prevent It All Garage

Top 5 Causes of Epoxy Floor Damage Smith u0026 Co Painting

How to repair epoxy coating failure? Duraamen

DIY Epoxy Garage Floor Coating Repair – Casper, WY

6 Reasons Why You Should Never Use Epoxy On Your Garage Floor

How to Recoat New Epoxy Over an Old Garage Floor Coating All

Garage Floor Paint Does Not Have To Peel

Garage Floor Coating u2013 Everything You Need to Know (2021

7 Factors that cause Epoxy Floors to FAIL

5 Common Epoxy Flooring Problems and How to Avoid Them

DIY Epoxy Garage Floor Coating Repair – Casper, WY

Related articles:

- Epoxy Flooring Repair

- Is Epoxy Flooring Safe

- Epoxy Flooring On Concrete

- Epoxy Flooring Cost Per Square Metre

- 3D Epoxy Flooring Cost

- Red Rhino Epoxy Flooring

- Epoxy Flooring New Jersey

- Epoxy Flooring Austin Tx

- Fosroc Self Leveling Epoxy Flooring

- Epoxy Flooring On Plywood

Epoxy Floor Paint Problems: A Comprehensive Guide

Introduction:

Epoxy floor paint has gained immense popularity in recent years due to its durability, versatility, and aesthetic appeal. It is commonly used in residential, commercial, and industrial settings. However, like any other product, epoxy floor paint is not without its share of problems. In this comprehensive guide, we will explore some of the most common issues that users may encounter when using epoxy floor paint and provide detailed explanations and solutions for each problem.

1. Peeling and Delamination:

One of the most frustrating problems with epoxy floor paint is peeling or delamination. This occurs when the bond between the concrete surface and the epoxy coating weakens or breaks, resulting in the detachment of the paint layer from the substrate. Several factors can contribute to this problem:

– Moisture: Excessive moisture in the concrete can prevent proper adhesion of the epoxy coating, leading to peeling. Moisture can come from various sources such as high humidity levels, water leaks, or insufficient curing time for new concrete.

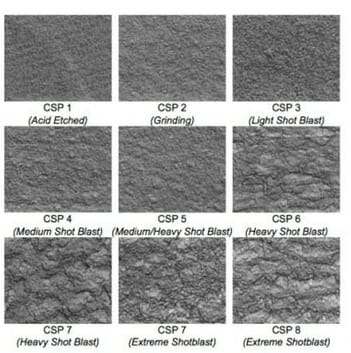

– Poor Surface Preparation: Inadequate surface preparation is a common cause of peeling. Proper cleaning, etching, and profiling of the concrete surface are essential to ensure optimal adhesion.

– Incompatible Substrates: Epoxy floor paint may not adhere well to certain substrates that have been previously coated with incompatible materials. It is crucial to remove any existing coatings or contaminants before applying epoxy.

– Improper Mixing: Incorrect mixing ratios or inadequate blending of epoxy components can compromise its integrity and lead to adhesion issues.

FAQs:

Q: How can I prevent peeling and delamination of epoxy floor paint?

A: To avoid these problems, it is essential to address moisture issues by conducting a thorough moisture test before applying epoxy. Adequate surface preparation, including cleaning and profiling the concrete substrate, is necessary for optimal adhesion. Additionally, following the manufacturer’s guidelines for epoxy mixing and application is crucial.

Q: Can I repair a peeling epoxy floor?

A: Yes, it is possible to repair a peeling epoxy floor. Start by removing the loose or delaminated paint using a scraper or grinder. Then, clean and prepare the surface as if applying a new coat of epoxy. Finally, reapply the epoxy according to the manufacturer’s instructions.

2. Blistering and Bubbling:

Blistering and bubbling are common problems that can occur during or after the application of epoxy floor paint. These issues manifest as raised areas or bubbles on the surface, detracting from the smooth finish and overall aesthetics of the floor. Some causes of blistering and bubbling include:

– Trapped Air or Moisture: When air or moisture becomes trapped underneath the epoxy coating, it can lead to blistering or bubbling. This can happen if the concrete surface contains excessive moisture, or if the coating is applied in humid conditions.

– Inadequate Drying Time: Insufficient drying time between coats or before subjecting the floor to foot traffic can cause solvents or air bubbles to be trapped within the epoxy layer.

– Incorrect Mixing: Improper mixing of epoxy components may result in chemical reactions that produce gas bubbles, leading to blistering.

FAQs:

Q: How can I prevent blistering and bubbling of epoxy floor paint?

A: To prevent these issues, it is crucial to ensure that the concrete substrate is sufficiently dry before applying epoxy. Conduct a moisture test to determine if there Is any excess moisture present. Additionally, allow adequate drying time between coats and before subjecting the floor to foot traffic. Properly mix the epoxy components according to the manufacturer’s instructions to avoid chemical reactions that can cause blistering or bubbling.

Q: Can I fix blistering and bubbling in an epoxy floor?

A: Yes, you can fix blistering and bubbling in an epoxy floor. Start by identifying the cause of the issue, such as trapped moisture or inadequate drying time. Address the underlying problem before attempting to repair the affected areas. This may involve removing the blistered or bubbled epoxy, allowing the surface to dry thoroughly, and then reapplying the epoxy according to the manufacturer’s instructions.

3. Discoloration:

Discoloration is another common problem that can occur with epoxy floor paint. It refers to changes in color or uneven color distribution on the surface of the floor. Some causes of discoloration include:

– UV Exposure: Epoxy coatings that are exposed to direct sunlight or UV radiation can experience color fading or discoloration over time.

– Inadequate UV Resistance: Some epoxy products may not have sufficient UV resistance, leading to discoloration when exposed to sunlight.

– Improper Mixing: Incorrectly mixing epoxy components or using incompatible additives can result in color variations or discoloration.

FAQs:

Q: How can I prevent discoloration of epoxy floor paint?

A: To prevent discoloration, choose an epoxy product that is specifically formulated for UV resistance if your floor will be exposed to sunlight. Follow the manufacturer’s guidelines for proper mixing and application of the epoxy. Additionally, consider using a topcoat or sealer with UV protection to further enhance the durability and color stability of the floor.

Q: Can I fix discoloration in an epoxy floor?

A: It may be challenging to fix discoloration in an epoxy floor once it has occurred. However, you can address the underlying issue, such as UV exposure or inadequate UV resistance, to prevent further discoloration. If the discoloration is minor, you may be able to apply a fresh coat of epoxy or a pigmented topcoat to even out the color. However, for significant discoloration, it may be necessary to remove the existing epoxy and start with a fresh application. Q: How can I prevent blistering and bubbling in an epoxy floor?

A: To prevent blistering and bubbling in an epoxy floor, it is important to follow the proper application procedures. This includes conducting a moisture test to ensure there is no excess moisture present before applying the epoxy. Additionally, allow adequate drying time between coats and before subjecting the floor to foot traffic. Properly mix the epoxy components according to the manufacturer’s instructions to avoid chemical reactions that can cause blistering or bubbling. Q: Can I repair blistering and bubbling in an epoxy floor?

A: Yes, you can repair blistering and bubbling in an epoxy floor. First, identify and address the underlying issue, such as trapped moisture or inadequate drying time. Remove the blistered or bubbled epoxy, allow the surface to dry thoroughly, and then reapply the epoxy according to the manufacturer’s instructions. This should help resolve the issue and prevent further blistering or bubbling.