Epoxy flooring coatings are cheap compared with some other flooring coatings. While concrete is regarded as virtually indestructible, it is not impervious to particular damage types, such as cosmetic, including scuffing, staining and cracking. But, if the area affected is considerable large, color mismatch is going to be evident. Hence, it's not intended for epoxy covering.

Here are Images about Epoxy Floor Coating Specifications

Epoxy Floor Coating Specifications

But there are various types of epoxy, and your choice must be based on how much traffic goes by on the flooring of yours from every day, just how frequently you will need to touch up, and of course, the price of every feature. If you use epoxy flooring for those tough places, you can rest assured that not simply will the surface look great for a long time, but will take use and tear like absolutely no other flooring material.

E707HB High Build 100% Solids Epoxy Floor Coating 20 Colors

By applying an epoxy covering on the concrete, the concrete is actually protecting. Marble is beautiful, but far more costly than decorated concrete. Epoxy floors coatings, particularly, are widely used in floor apps. Epoxies are used to produce sparkling, clean and durable flooring. Also, you mustn't apply epoxy layer if your flooring was used with concrete sealer. Epoxy floor color makes areas look more professional.

Images Related to Epoxy Floor Coating Specifications

Industrial Floorings FAQs PSC Flooring Ltd. Epoxy Flooring

What is Epoxy Flooring? Read our Ultimate Guide Thermal-Chem

For the Architect: Epoxy Floor Specs for Your Project

6009 Epoxy Floor Coating Industrial u0026 Commercial Low Temp 35°F 100% Solids Quick Cure

Epoxy Flooring: What You Must Know u0026 Should Avoid

E183HB Epoxy Floor Coating High Build Quick Back In-Service Abrasion u0026 Chemical Resistant 19 Colors

What is Epoxy Flooring? Read our Ultimate Guide Thermal-Chem

Your Epoxy u0026 Floor Coating Questions Answered – FAQs – Florock

Industrial Flooring Epoxy Coatings ArmorGarage

Epoxy Floor Coatings vs. Epoxy Paint: Just How Different Are They

HyperREZ UV Low Temp 40°F High Build Epoxy Concrete Floor Coating 100% Solids

ESD Epoxy Floor Paint

Related articles:

- Epoxy Floor Coating Tips

- Metallic Epoxy Floor Designs

- Epoxy Flooring Contractors

- Epoxy Floor Coating Material

- Epoxy Floor Coating With Flakes

- Epoxy Floor Finishes Concrete

- Epoxy Flooring Design

- DIY Epoxy Flooring Systems

- Epoxy Floor Coating Designs

- Epoxy Flooring Basement

Epoxy floor coatings are a popular choice for industrial, commercial, and residential spaces due to their durability, resistance to chemicals and stains, and easy maintenance. When considering an epoxy floor coating for your space, it is essential to understand the specifications that will ensure a successful installation and long-lasting performance.

Types of Epoxy Floor Coatings:

There are several types of epoxy floor coatings available in the market, each with its unique characteristics and applications. The most common types include solvent-based epoxy, water-based epoxy, 100% solids epoxy, and metallic epoxy. Solvent-based epoxies are known for their high durability and resistance to chemicals but may emit strong fumes during installation. Water-based epoxies are environmentally friendly options that have low odor but may require more coats for adequate protection. 100% solids epoxies are the most durable option with no volatile organic compounds (VOCs) but can be more challenging to apply. Metallic epoxies create a luxurious, marbled effect and are often used in decorative settings.

FAQs:

Q: What is the difference between solvent-based and water-based epoxy floor coatings?

A: Solvent-based epoxies contain solvents that evaporate during the curing process, while water-based epoxies use water as a carrier instead of solvents. Solvent-based epoxies tend to be more durable but may emit strong odors during installation, while water-based epoxies are eco-friendly with low odor.

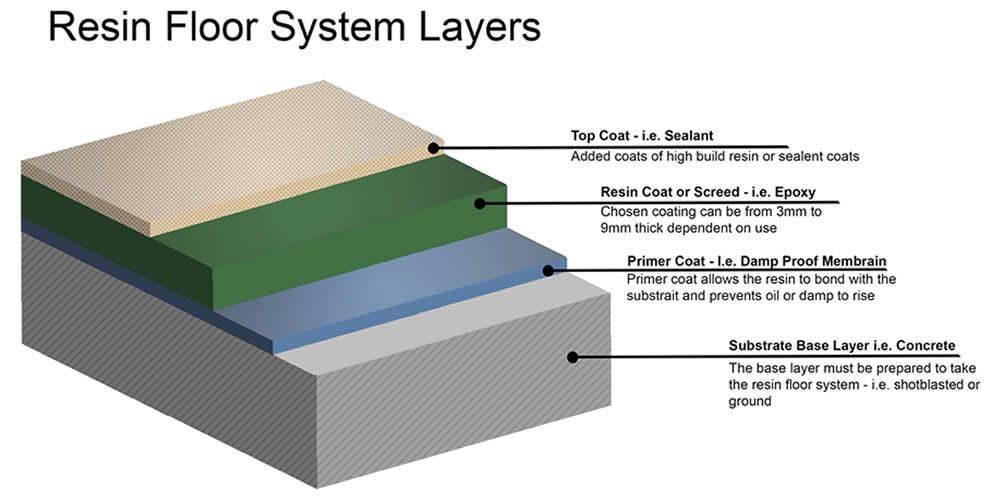

Preparation of Substrate:

Proper preparation of the substrate is crucial for the success of an epoxy floor coating installation. The substrate must be clean, dry, and free of any contaminants such as oil, grease, dust, or previous coatings. Any cracks or imperfections in the substrate should be repaired before applying the epoxy coating to ensure a smooth and even finish.

FAQs:

Q: Can I apply an epoxy floor coating over existing tiles?

A: Yes, you can apply an epoxy floor coating over existing tiles as long as they are in good condition and properly prepared. It is essential to thoroughly clean and etch the tiles before applying the epoxy coating to ensure proper adhesion.

Application Thickness:

The thickness of the epoxy floor coating plays a significant role in its durability and performance. Most standard epoxy coatings range from 1-3 millimeters in thickness, while high-build or self-leveling epoxies can be applied up to 5 millimeters thick for additional protection.

FAQs:

Q: How thick should an epoxy floor coating be for industrial applications?

A: For industrial applications where heavy machinery or equipment will be used, it is recommended to apply an epoxy floor coating with a thickness of at least 3-5 millimeters for maximum durability and impact resistance.

Curing Time:

The curing time of an epoxy floor coating refers to the time it takes for the coating to fully harden and cure. Curing times can vary depending on factors such as temperature, humidity levels, and the type of epoxy used. Typically, epoxy coatings can take anywhere from 24 hours to 7 days to cure completely.

FAQs:

Q: How long do I need to wait before walking or placing heavy objects on my newly installed epoxy floor coating?

A: It is recommended to wait at least 24-48 hours before walking on an epoxy floor coating and up to 7 days before placing heavy objects or machinery on the surface to allow for proper curing and adhesion.

Topcoat Options:

To enhance The durability and longevity of an epoxy floor coating, a topcoat is often applied after the base coat has cured. Topcoats can provide additional protection against abrasion, UV rays, and chemical spills, as well as improve the aesthetics of the floor. Common topcoat options include clear epoxy, polyurethane, or polyaspartic coatings.

FAQs:

Q: Do I need to apply a topcoat over my epoxy floor coating?

A: While not always necessary, applying a topcoat over an epoxy floor coating can enhance its durability and performance, especially in high-traffic or industrial settings. A topcoat can also provide additional protection against wear and tear, UV rays, and chemical exposure.

Maintenance and Care:

Proper maintenance and care are essential for prolonging the lifespan of an epoxy floor coating. Regular cleaning with a mild detergent and water can help prevent dirt and grime buildup, while avoiding harsh chemicals or abrasive cleaners can protect the integrity of the coating. Periodic resealing or recoating may also be necessary to maintain the appearance and performance of the epoxy floor.

FAQs:

Q: How often should I reseal or recoat my epoxy floor?

A: The frequency of resealing or recoating an epoxy floor depends on factors such as traffic levels, exposure to chemicals or UV rays, and overall wear and tear. In general, it is recommended to reseal or recoat an epoxy floor every 2-5 years to maintain its appearance and performance.

In conclusion, metallic epoxies offer a luxurious marbled effect for decorative settings, proper substrate preparation is crucial for successful installation, thickness and curing time play key roles in durability, topcoat options can enhance protection and aesthetics, and regular maintenance is essential for prolonging the lifespan of an epoxy floor coating. Remember to follow manufacturer guidelines and consult with professionals for best results when installing and caring for an epoxy floor coating. If you have any further questions or need assistance with your epoxy floor coating project, feel free to reach out to professionals in the field for guidance and support. With proper installation, care, and maintenance, your epoxy floor coating can provide a beautiful and durable flooring solution for many years to come. Overall, metallic epoxy floor coatings offer a unique and stylish flooring option that can enhance the aesthetic appeal of any space. By following proper installation techniques, including substrate preparation, thickness considerations, and curing times, you can ensure a durable and long-lasting finish. Additionally, applying a topcoat can further protect the epoxy coating and enhance its performance in high-traffic areas.

Regular maintenance, such as cleaning with mild detergents and avoiding harsh chemicals, is essential for preserving the appearance and integrity of the epoxy floor coating. Periodic resealing or recoating every 2-5 years can help maintain its longevity and performance over time.

If you have any questions or need assistance with your epoxy floor coating project, don’t hesitate to reach out to professionals for guidance. With proper care and maintenance, your metallic epoxy floor coating can continue to impress for years to come.