This can help you save the future hassles. Less permeable stone floor variations such as flagstones, granite and slate can make for an ideal basement floor. Basements may be fantastic. Talk to flooring professionals regarding the best choices for the specific basement of yours and the possible obstacles that you've with flooring. Basement floor covering does not have to be bland to be purposeful.

Here are Images about Epoxy Basement Floor Rustoleum

Epoxy Basement Floor Rustoleum

To start with, it is one spot in your home which usually experiences leaks. Before selecting just beginning with the basement flooring preparation of yours, there are some things that you need to check. You can furthermore look for some engineered hardwood flooring or laminate which has been created to better handle humidity changes.

HOW TO apply rustoleum to basement floor. (includes instructions

The best part is the fact that there are several choices about how you are able to have a wonderful, worth it flooring. The flooring type you select for the basement of yours will depend on individual preference and possible environmental factors. Basement flooring has several types out in the market, that makes the choice truly difficult.

Images Related to Epoxy Basement Floor Rustoleum

EPOXYSHIELD® Basement Floor Tint Base Kit Product Page

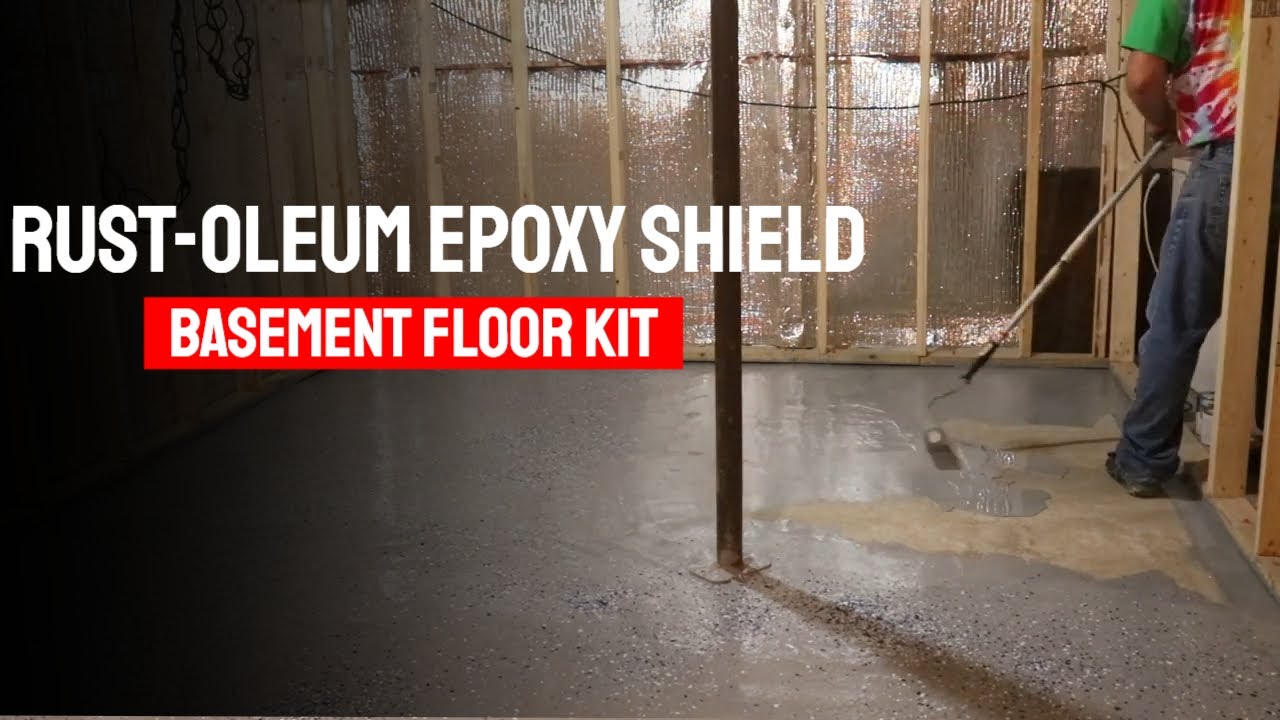

Rust-Oleum Epoxy Shield Basement Floor Kit

EPOXYSHIELD® Basement Floor Coating Kit Product Page

rustoleum epoxy shield for basement

EPOXYSHIELD® Semi-Gloss Professional Floor Coating Kit – 256 oz

Rust-Oleum EpoxyShield 1 gal. Gray Satin Basement Floor Coating

Buy Rust-Oleum EpoxyShield Basement Floor Coating Kit 120 Oz., Tan

Paint your basement floor

Concrete and Garage Floor Paint Brand Page

Rust-Oleum EpoxyShield 1 gal. Gray Satin Basement Floor Coating

Rust-Oleum EpoxyShield

Basement floor done with Rust-Oleum Rocksolid Epoxy Marble kit

Related articles:

- Basement Floor Remodel

- How To Repair Concrete Cracks In Basement Floor

- Basement Floor Epoxy Colors

- Holmes On Homes Basement Floor

- Basement Wood Flooring Options

- Water Seepage Basement Floor

- Concrete Basement Floor Paint Colors

- Basement Remodeling Flooring Ideas

- Ranch Style Floor Plans With Finished Basement

- Basement Floor Drain Float Plug

Epoxy Basement Floor Rustoleum: A Comprehensive Guide

Basements can be one of the most difficult spaces to improve in a home. Not only is it often damp and cold, but it’s also usually dark and cramped. One way to remedy these issues is to install an epoxy basement floor Rustoleum. This type of flooring provides a durable and attractive finish that will last for years. It’s also easy to maintain and clean, making it an ideal choice for those looking to make the most out of their basement areas. In this comprehensive guide, we’ll discuss all you need to know about epoxy basement floor Rustoleum, including the benefits, installation process, and maintenance tips.

What is Epoxy Basement Floor Rustoleum?

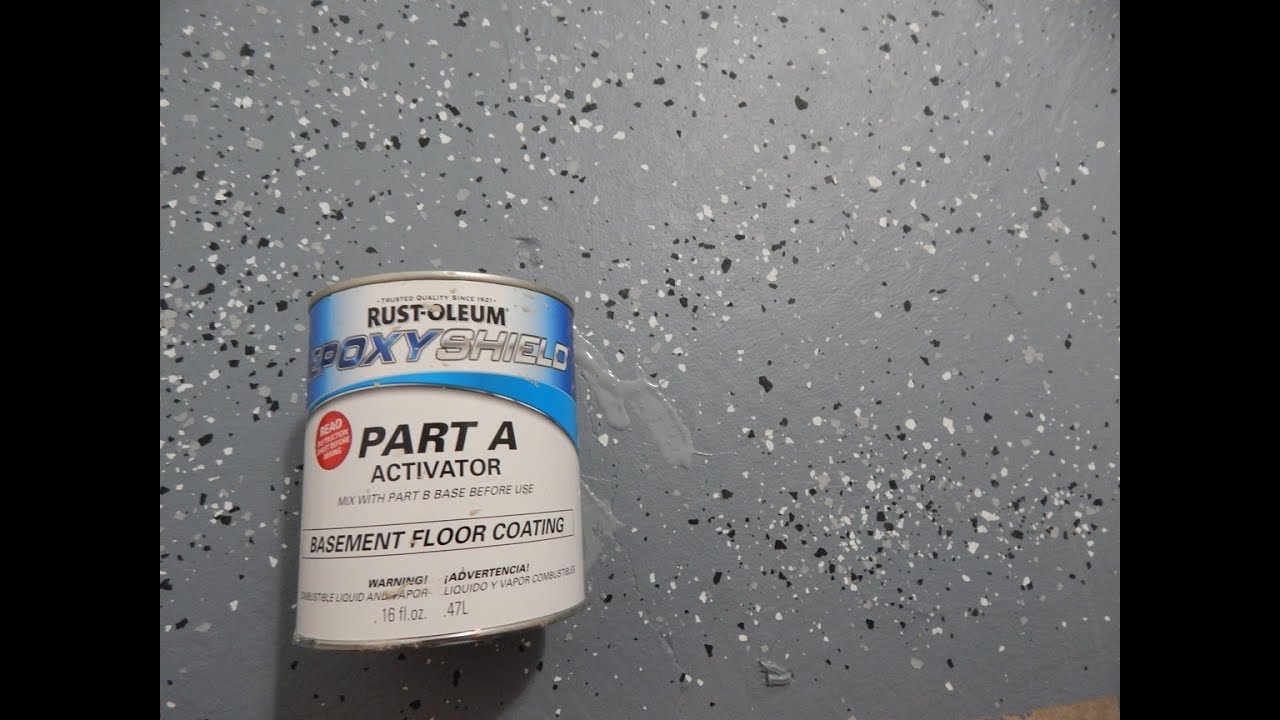

Epoxy basement floor Rustoleum is a combination of two components: epoxy resin and hardener. When mixed together, these two components form a strong bond that cures into an impermeable layer on your concrete surface. This layer provides protection against moisture, stains, abrasion, and other damages that can occur in your basement area. It also creates a waterproof barrier that helps prevent mold and mildew growth. Additionally, epoxy basement floor Rustoleum offers superior adhesion over traditional paints or stains and can be customized with decorative chips or flakes for a unique look.

Benefits of Installing Epoxy Basement Floor Rustoleum

Installing epoxy basement floor Rustoleum brings several advantages to homeowners. First and foremost, it increases the value of any home as it creates a more attractive space with improved aesthetics. The impermeable layer also offers superior protection against water damage, which can occur due to flooding or high humidity levels. Additionally, this type of flooring is incredibly easy to maintain; it requires only occasional mopping or sweeping to keep it looking its best. Epoxy basement floor Rustoleum is also highly durable; when properly installed and cared for, this type of flooring can last for years without needing replacement.

Installation Process

Installing epoxy basement floor Rustoleum requires some preparation before starting the project. First, any existing paint or coatings must be removed from the concrete surface using a power washer or chemical stripper. Once the surface has been cleaned thoroughly, it must be allowed to dry completely before applying the epoxy mixture. Once ready, spread the resin/hardener mix evenly over the concrete surface using a roller brush; make sure to cover any cracks or holes in order to ensure proper adhesion. Once applied, allow the mixture to cure completely before adding decorative chips or flakes if desired.

Maintenance Tips

Properly caring for your epoxy basement floor Rustoleum is key in ensuring its longevity for years to come. Start by sweeping away dirt and debris regularly as this will help protect against scratches caused by large particles in traffic areas. To clean spills or stains, use warm water mixed with detergent; avoid using abrasive cleaners as they may damage the surface of your epoxy basement flooring over time. Finally, avoid dragging heavy furniture across your floors; instead use wide mats or felt pads underneath furniture legs in order to prevent scratches or dents from occurring.

FAQs

Q: How Long does epoxy basement floor Rustoleum last?

A: When properly installed and cared for, epoxy basement floor Rustoleum can last for up to 10 years.