Throughout the winter, it is going to be much colder and definitely the environment in the house is a lot drier than the summer months which in turn leads to very small spaces developing in between the separate planks because the wood contracts. Forests are a renewable resource we can utilize for a very long time to come. These specification are discussed in more detail at our internet site.

Images Related to Engineered Wood Flooring Maple

Engineered Wood Flooring Maple

Reclaimed woods are steeped inside historical past. With hardwood floors not a good deal has altered since the 70s to improve it's tolerance of regular living circumstances. With ease of maintenance and also a wide array of shopping venues, owning an engineered wood flooring has never been easier. Darker colors are additionally perfect for bedrooms as well as office rooms, although the wood should be stronger since these rooms have significant furniture that is likely to be moved frequently.

BuildDirect® – Flooring, Decking, Siding, Roofing, and More

The choices of wood species is also incredible, hence it may be a difficult choice, however, it is going to be a decision the homeowner is going to be thrilled to enjoy for decades to come. Growing your wood floor lacquered will protect it and make it go longer although some people want to have an even more organic look to their wood floors and as such choose not to lacquer the floors of theirs.

Lifeproof Virgin River Maple 6.5 in. W x Varying Length Engineered

Lifeproof Carlsbad Maple 7 mm T x 6.5 in. W x Varying Length

1/2″ x 3-1/4″ Natural Maple Prefinished Engineered Wood Floor

Discount 5″ x 5/8″ Maple 4mm Wear Layer Prefinished Engineered Hardwood Flooring by Hurst Hardwoods Hurst Hardwoods

Hard Maple Engineered Flooring 5/8″ x 5″ Select Grade

Engineered Hardwood Maple Natural 6″ Click in Engineered Wood

Maple Prefinished Engineered Smooth u201cNaturalu201d Hardwood Flooring

Canadian Maple Toffee

Maple Engineered Click Lock Hardwood Flooring $1.99/SQFT Made In USA eBay

Hennepin Maple Engineered Hardwood Flooring – WoodHouse Flooring

Malibu Wide Plank Maple Cardiff 1/2 in. Thick x 7-1/2 in. Wide x

SMARTCORE (Sample) Naturals Prefinished Blugrass Trail Maple Smooth/Traditional Engineered Hardwood Flooring Sample

Related articles:

- Natural Wood Floor Stain

- Oak Wood Flooring

- Birch Wood Flooring Reviews

- Wood Floor Damage Repair

- Dove Grey Wood Flooring

- Engineered Wood Floor Bathroom

- What Is Composite Wood Flooring

- Wood Floor Covering Options

- Black Solid Wood Flooring

- Best Wood Floor Filler

Engineered Wood Flooring Maple: The Perfect Blend of Beauty and Durability

Introduction:

When it comes to choosing the flooring for our homes, we want something that not only looks beautiful but also stands the test of time. Engineered wood flooring maple is an excellent choice that combines the natural beauty of maple wood with the durability and stability of engineered construction. In this article, we will explore the features and benefits of engineered wood flooring maple, along with some commonly asked questions to help you make an informed decision.

1. What is Engineered Wood Flooring Maple?

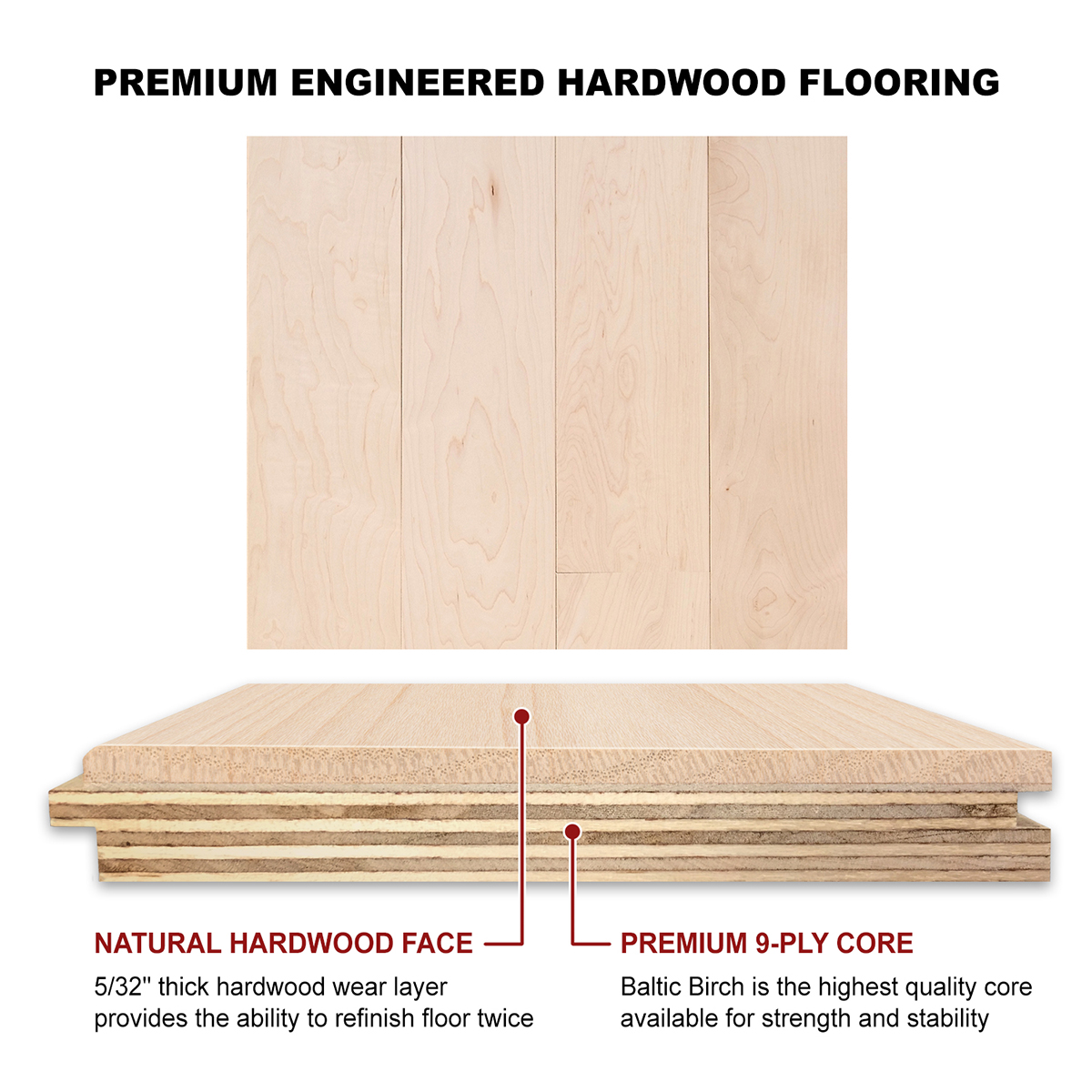

Engineered wood flooring maple is a type of hardwood flooring that is constructed using layers of real maple wood veneer on top of a high-quality plywood or fiberboard core. Each layer is placed perpendicular to the adjacent layer, creating a cross-grain structure that enhances stability and reduces the risk of warping or shrinking. The top layer, also known as the wear layer, is made from solid maple wood, providing the authentic beauty and texture of natural wood.

2. Why Choose Engineered Wood Flooring Maple?

a) Durability and Stability:

One of the primary reasons to choose engineered wood flooring maple is its exceptional durability and stability. The cross-grain construction prevents the planks from expanding or contracting due to changes in humidity or temperature, making it suitable for any room in your home, including areas with higher moisture levels such as bathrooms and basements. Additionally, the multi-layered composition adds strength to the flooring, making it resistant to dents, scratches, and wear.

b) Natural Beauty:

Maple wood is highly sought after for its stunning appearance and unique grain patterns. Engineered wood flooring maple captures the essence of this natural beauty, showcasing its rich tones ranging from creamy whites to warm reddish-browns. The smooth surface of the maple veneer adds elegance and sophistication to any space, enhancing its overall aesthetic appeal.

c) Versatility:

Engineered wood flooring maple is available in various styles, finishes, and plank sizes, allowing you to find the perfect fit for your home’s décor. Whether you prefer a traditional or contemporary look, there is a wide range of options to choose from. Additionally, engineered wood flooring maple can be installed using different methods, including glue-down, nail-down, or floating installation, providing flexibility based on your specific requirements.

3. How to Install Engineered Wood Flooring Maple?

Installing engineered wood flooring maple can be a DIY project if you have some experience with basic carpentry skills. However, it is recommended to hire a professional installer for optimal results. Here are the general steps involved in the installation process:

a) Preparation:

Start by preparing the subfloor. Ensure it is clean, dry, and level. Remove any existing flooring and fix any imperfections in the subfloor. It is important to acclimate the engineered wood planks by storing them in the room where they will be installed for at least 48 hours before installation.

b) Underlayment:

Depending on the type of subfloor and installation method chosen, an underlayment may be required. The underlayment provides cushioning and helps reduce noise.

c) Layout:

Plan the layout of the flooring by measuring the room’s dimensions and determining the best starting point. It is generally recommended to start from a wall that runs parallel to the floor joists.

d) Installation:

Begin by laying down the first row of planks, ensuring it is straight and tightly fitted together. Use spacers along the edges To maintain the proper expansion gap. Install the subsequent rows by interlocking the tongue and groove edges of the planks. Use a tapping block and mallet to ensure a secure fit. Cut the planks as needed to fit around obstacles like doorways or vents.

e) Finishing touches:

Once all the planks are installed, remove the spacers and install baseboards or trim to cover the expansion gap along the edges of the room. Clean any adhesive or debris from the surface of the flooring.

f) Maintenance:

To keep your engineered wood flooring maple looking its best, it is important to follow proper maintenance practices. Regularly sweep or vacuum to remove dirt and dust. Wipe up spills immediately to prevent moisture damage. Use a damp mop with a mild cleaner specifically formulated for wood floors to clean any stains or sticky residue.

In conclusion, engineered wood flooring maple offers durability, natural beauty, and versatility. When installed correctly and maintained properly, it can be a long-lasting and attractive addition to any home. It is important to note that the specific installation process may vary depending on the manufacturer’s instructions and the specific type of engineered wood flooring maple being used. It is always recommended to consult the manufacturer’s guidelines for the best installation practices.

In addition to the steps mentioned above, it is also important to consider factors such as acclimating the flooring to the room’s temperature and humidity levels, as well as using appropriate tools and techniques for cutting and fitting the planks.

Overall, installing engineered wood flooring maple can be a rewarding project that adds beauty and value to your home. Whether you choose to do it yourself or hire a professional installer, proper preparation, layout planning, and attention to detail are key to achieving a successful installation. To summarize, here are the key steps for installing engineered wood flooring maple:

1. Acclimate the flooring by storing it in the room where it will be installed for at least 48 hours before installation.

2. Determine if an underlayment is required based on the subfloor and installation method chosen.

3. Plan the layout of the flooring by measuring the room’s dimensions and determining the best starting point.

4. Begin installation by laying down the first row of planks, ensuring they are straight and tightly fitted together.

5. Use spacers along the edges to maintain the proper expansion gap between planks.

6. Install subsequent rows by interlocking the tongue and groove edges of the planks.

7. Use a tapping block and mallet to ensure a secure fit.

8. Cut planks as needed to fit around obstacles like doorways or vents.

9. Once all planks are installed, remove spacers and install baseboards or trim to cover the expansion gap along the edges of the room.

10. Clean any adhesive or debris from the surface of the flooring.

11. Regularly sweep or vacuum to remove dirt and dust.

12. Wipe up spills immediately to prevent moisture damage.

13. Use a damp mop with a mild cleaner specifically formulated for wood floors to clean any stains or sticky residue.

It is important to consult the manufacturer’s guidelines for specific installation instructions and consider factors such as acclimation and proper tools and techniques for cutting and fitting planks. Whether you choose to DIY or hire a professional installer, proper preparation, layout planning, and attention to detail are crucial for a successful installation of engineered wood flooring maple.