Many people cover their concrete floor with carpets but one can't argue with spotless ability and the durability of concrete. Water based paints are generally not a great idea with regards to concrete flooring, as they typically do not adhere to the surface area very nicely.

Here are Images about Domestic Concrete Floor Construction

Domestic Concrete Floor Construction

Sealants, like a polymer flooring seal, provide many advantages to interior and exterior floors and are a very good addition to a concrete floor maintenance program. Caring for your decorative concrete floors isn't very different compared to the normal maintenance you perform in just about any aspect of the home of yours.

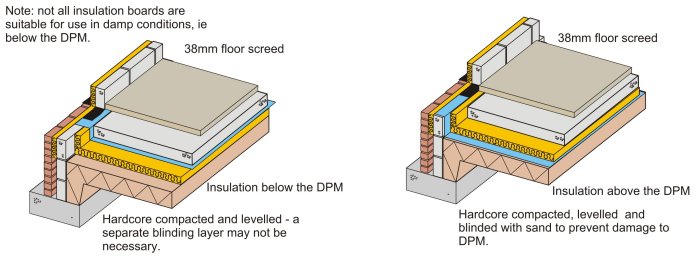

How to build an extension: part 3 concrete floor slab

The mantra is covering the current concrete floor with a slim cement-based overlay to create a fresh brand new photo to work on. As soon as they have cured, latest concrete installations are easily and inexpensively brought to a shine. When putting in polished concrete flooring surfaces, the concrete is sanded with a diamond surfaced polishing machine.

Images Related to Domestic Concrete Floor Construction

Insulated Concrete Flooring Thermabeam™ GB FP McCann

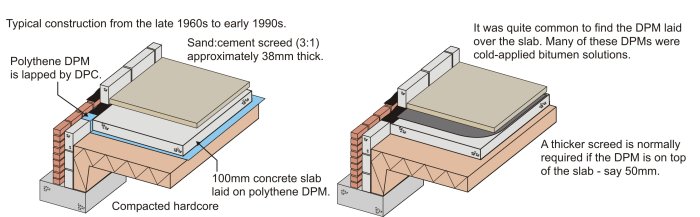

Evolution of Building Elements

Evolution of Building Elements

Floor Structure Guide

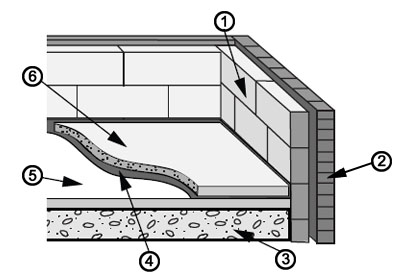

underfloor heating supplied and installed in the UK by Borders

Concrete Floor Slab Construction Process – The Constructor

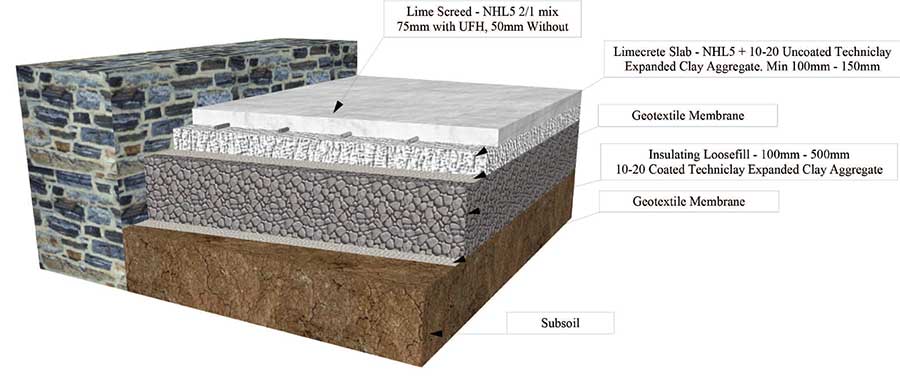

Green Building Design: Materials u0026 Techniques

6. Ground Floors – Construction Studies

How to construct a floating floor Insulation Kingspan Great

What Is Floating Slab Floating Slab Construction How to Build a

Concrete Floor Slabs Concrete Construction Magazine

Evolution of Building Elements

Related articles:

- Concrete Floor Inside House

- Leveling Old Concrete Floor

- Smooth Concrete Floor Finish

- Concrete Floor Heating Installation

- Polished Concrete Floor Over Wood Subfloor

- How To Pour A Concrete Floor Over A Basement

- Concrete Floor Cleaning Machines For Rent

- Best Epoxy Concrete Floor Paint

- Concrete Floor Interior House

- Concrete Flooring Pretoria

Domestic Concrete Floor Construction: A Comprehensive Guide

Introduction:

A well-constructed concrete floor is the foundation of a sturdy and durable home. Whether you are building a new house or renovating an existing one, understanding the process of domestic concrete floor construction is essential. This article provides a detailed guide, outlining the steps involved in constructing a concrete floor, along with frequently asked questions to address common concerns.

1. Planning and Preparation:

Before beginning any construction project, thorough planning and preparation are crucial. This stage involves several important considerations, such as determining the purpose of the concrete floor, its load-bearing capacity, and the type of finish desired.

FAQ 1: What factors should I consider when planning a domestic concrete floor?

Answer: When planning a domestic concrete floor, you should consider factors such as the intended use of the space (e.g., garage, basement), expected foot traffic, potential weight loads (e.g., vehicles), desired finish (e.g., polished or textured), and any specific requirements for insulation or waterproofing.

2. Site Preparation:

The next step in domestic concrete floor construction involves site preparation. This includes clearing the area of any vegetation or debris, ensuring proper drainage, and leveling the ground to create a firm base for the concrete slab.

FAQ 2: How do I ensure proper drainage for my domestic concrete floor?

Answer: To ensure proper drainage for your concrete floor, it is essential to slope the surrounding area away from the house or structure. This can be achieved by grading the land or installing French drains to divert water away from the foundation.

3. Formwork Installation:

Formwork serves as a mold for pouring and shaping the concrete slab. It consists of temporary structures made from wood or metal that define the dimensions and shape of the floor. The formwork must be accurately aligned and securely fastened to prevent any movement during pouring.

FAQ 3: What materials are commonly used for formwork?

Answer: Plywood, timber, and metal are commonly used materials for formwork. Plywood provides flexibility and ease of installation, while timber is cost-effective and can be easily customized. Metal formwork offers durability and is often used for large-scale projects.

4. Reinforcement Placement:

To enhance the strength and durability of the concrete floor, reinforcement is added before pouring the concrete. This typically involves installing a mesh of steel bars or using fiber-reinforced concrete to provide structural support.

FAQ 4: Do all domestic concrete floors require reinforcement?

Answer: The need for reinforcement depends on factors such as the size of the floor, expected loads, and local building codes. While smaller residential floors may not require extensive reinforcement, larger areas or those subjected to heavy loads should incorporate reinforcement for added strength.

5. Pouring and Compacting Concrete:

Once the formwork and reinforcement are in place, it is time to pour and compact the concrete. The concrete mixture should be carefully prepared according to the required specifications, ensuring an optimal balance of cement, aggregates, water, and any additives.

FAQ 5: How can I ensure proper compaction of the concrete?

Answer: Proper compaction of the concrete is crucial to eliminate air voids and achieve a dense, solid floor. This can be achieved using mechanical vibrators or by employing hand tools such as trowels or screeds. The compaction process should be carried out evenly to avoid any inconsistencies in thickness or density.

6. Finishing Techniques:

After pouring and compacting the concrete, various finishing techniques can Be applied to enhance the appearance and functionality of the floor. This can include techniques such as smoothing the surface with a trowel, creating texture with brooms or stamps, or applying decorative coatings or finishes.

FAQ 6: What are some popular finishing options for concrete floors?

Answer: Popular finishing options for concrete floors include polishing, staining, and sealing. Polishing creates a glossy and smooth surface, while staining adds color and depth. Sealing provides protection against stains, moisture, and wear and tear.

7. Curing and Maintenance:

Once the concrete is poured and finished, it is important to properly cure it to ensure maximum strength and durability. Curing involves keeping the concrete moist and at the appropriate temperature for a specified period of time. Regular maintenance should also be carried out to keep the floor clean and free from damage.

FAQ 7: How long does concrete take to cure?

Answer: The curing time for concrete can vary depending on factors such as temperature, humidity, and the type of cement used. In general, concrete reaches its maximum strength after 28 days of curing. However, it is important to follow specific guidelines provided by the manufacturer or contractor.

By following these steps and considering the frequently asked questions, you can ensure a successful installation of a domestic concrete floor that is strong, functional, and visually appealing. Remember to always consult with professionals and adhere to local building codes to ensure proper installation and compliance. Additionally, it is important to consider the load requirements and intended use of the floor when designing and installing a domestic concrete floor. This will help determine the necessary thickness and reinforcement needed to support heavy loads. Consulting with professionals and adhering to local building codes will also ensure that the installation is done correctly and meets all safety standards.

In summary, the key steps for installing a domestic concrete floor include preparing the subgrade, constructing formwork, reinforcing the concrete, pouring and compacting the concrete, applying finishing techniques, curing the concrete, and maintaining the floor. By following these steps and considering the frequently asked questions, you can achieve a strong, functional, and visually appealing concrete floor for your home.