In the past, concrete floors had been principally used in factories, showrooms, schools and offices but due to the effects that could be achieved using stains and dyes, it is starting to be very popular in modern houses. The best way to clean your concrete floor with a vacuum which has been outfitted with a head that is suited for floorboards.

Here are Images about Concrete Floor Topping Mix Ratio

Concrete Floor Topping Mix Ratio

Some advantages of polished concrete flooring are the long life of its, along with the virtually endless style alternatives offered. Concrete flooring is excellent for warm climates as it stays cool even in the hottest weather. If you're planning the floor of your office or home to be concreted, you'll find a handful of things you have to check.

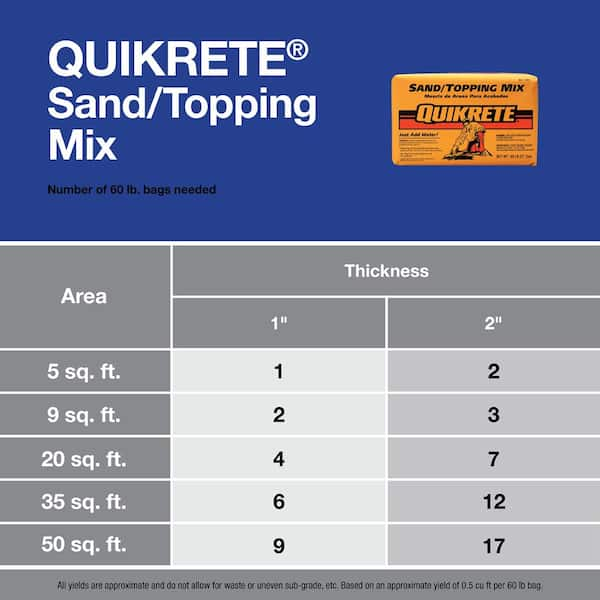

Quikrete 60 lb. Sand/Topping Mix 110360 – The Home Depot

Hiring professional concreters or concrete contractors may cost a little though you are assured of an even better outcome. Concrete floors are significantly recommended through the American Lung Association for people with asthma and allergies. All of the above forms of polished concrete floors can be finished in huge appearance and styles.

Images Related to Concrete Floor Topping Mix Ratio

FLOOR-TOP STG – Concrete Floor Topping – W. R. Meadows

Topping Concrete – Work Procedure, Types and Advantages – The

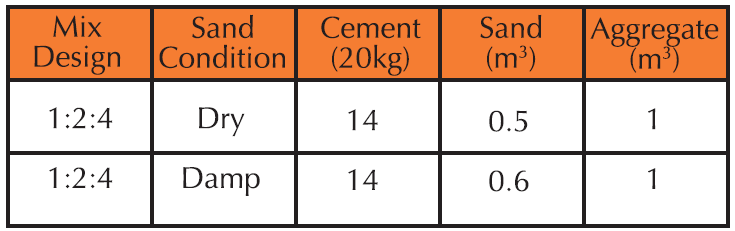

Mix Ratio of Sand-Cement Screed for Floors – The Constructor

Mix Design Fundamentals: Considerations for concrete for slabs-on

Preparing for a Topping Concrete Construction Magazine

Mix Design Fundamentals: Considerations for concrete for slabs-on

How To Make and Mix Floor Screed

What Is Concrete Topping Topping Slab Definition Types of

Mix Design Fundamentals: Considerations for concrete for slabs-on

Concrete Screed Ratio Mix How to calculate Volume Cement Aggregates Water mix

Dealing with Ambient Conditions When Placing Concrete Toppings

Concrete vs Floor Screeds: What is The Difference? All Things

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Concrete Floor Topping Mix Ratio: A Comprehensive Guide

Introduction:

Concrete floor toppings are a popular choice for enhancing the durability, aesthetics, and functionality of floors in various settings, including commercial and residential spaces. The mix ratio plays a crucial role in achieving the desired strength and appearance of the concrete topping. In this article, we will delve into the details of the concrete floor topping mix ratio, discussing its significance, components, and the factors that influence it. Additionally, we will address common FAQs to provide a comprehensive understanding of this important aspect of concrete floor construction.

1. Understanding the Mix Ratio:

The mix ratio refers to the proportion of different materials used in the concrete mixture. When it comes to concrete floor toppings, the mix ratio determines the strength, workability, and finishing properties of the final product. It consists of three main components: cement, aggregate (sand or fine aggregates), and water. The ratio in which these components are mixed depends on several factors like intended use, curing conditions, and specific requirements.

2. Components of Concrete Floor Topping Mix Ratio:

a) Cement: Cement is a binding material that holds the concrete together. It provides strength and stability to the mixture. The type of cement used can vary depending on project requirements. Common types include Portland cement, blended cements (such as Portland pozzolana cement), and specialty cements (such as sulfate-resistant cement).

b) Aggregate: Aggregates are inert granular materials that occupy most of the volume in a concrete mixture. They provide bulk and stability to the topping mix. Fine aggregates, such as sand or crushed stone dust, are commonly used in concrete floor toppings.

c) Water: Water is an essential component in any concrete mixture as it reacts with cement to form a strong bond. The amount of water added affects the workability and strength of the topping mix. It is crucial to strike a balance between adding enough water for proper hydration and avoiding excessive water content that could compromise the strength.

3. Factors Influencing the Mix Ratio:

a) Strength Requirements: The intended use of the concrete floor topping determines its strength requirements. For example, industrial floors may require higher compressive strength than residential floors. The mix ratio is adjusted accordingly to achieve the desired strength.

b) Workability: Workability refers to the ease with which a fresh concrete mixture can be placed, compacted, and finished. It depends on factors like aggregate size, shape, and grading, as well as the water-cement ratio. Achieving the right workability is crucial for proper placement and finishing of the concrete floor topping.

c) Curing Conditions: The curing conditions also influence the mix ratio. The curing process involves providing adequate moisture and temperature conditions to ensure proper hydration of cement and development of desired strength. In situations where curing conditions are less than ideal, adjustments in the mix ratio may be necessary to compensate for potential loss of strength during curing.

4. FAQs:

a) What is the recommended water-cement ratio for concrete floor toppings?

The water-cement ratio typically ranges from 0.40 to 0.50 for concrete floor toppings. However, it may vary depending on factors like desired workability and strength requirements. It is always best to consult with a structural engineer or a concrete specialist to determine the precise water-cement ratio for your specific project.

b) Can additives be used in concrete floor toppings?

Yes, additives can be incorporated into the concrete mixture to enhance certain properties. For example, Retarders can be used to slow down the setting time of the concrete, allowing for better workability and finishing. Additionally, admixtures such as air entraining agents can be added to improve freeze-thaw resistance. It is important to consult with a concrete specialist or manufacturer to determine the appropriate additives for your specific project.

c) How long does it take for a concrete floor topping to cure?

The curing time for a concrete floor topping can vary depending on factors such as mix design, ambient conditions, and desired strength. Generally, it is recommended to allow at least 7 days for curing before subjecting the topping to heavy loads or traffic. However, full strength development can take up to 28 days or longer. It is important to follow proper curing practices, including keeping the topping moist and protected from extreme temperatures, to ensure optimal strength development.

d) Can colored pigments be added to concrete floor toppings?

Yes, colored pigments can be added to concrete floor toppings to achieve desired aesthetics. Pigments are available in various forms, including powders and liquid dispersions. They are typically added during the mixing process to evenly distribute the color throughout the topping. It is important to use pigments specifically designed for use in concrete and follow manufacturer’s guidelines for proper dosage and mixing procedures. E) What are the factors to consider when choosing the shape of a concrete floor topping?

When choosing the shape of a concrete floor topping, several factors should be considered. These include the intended use of the space, aesthetic preferences, maintenance requirements, and any functional or practical considerations. For example, a curved shape may be more visually appealing but could be more challenging to install and maintain compared to a simple rectangular shape. It is important to consult with design professionals or concrete specialists to determine the most suitable shape for your specific project.

f) How is the grading of aggregates important in concrete floor toppings?

The grading of aggregates used in concrete floor toppings plays a crucial role in achieving the desired characteristics of strength, workability, and durability. Properly graded aggregates ensure that voids between particles are minimized, resulting in a dense and cohesive mixture. This improves the strength and durability of the topping. Additionally, well-graded aggregates provide better workability by allowing for better distribution of water and cement throughout the mixture. It is important to select aggregates with appropriate gradation for optimal performance of the concrete floor topping.

g) What are some common methods for finishing concrete floor toppings?

There are several common methods for finishing concrete floor toppings, depending on the desired appearance and functionality. These include troweling, brooming, stamping, and polishing. Troweling involves using a steel or power trowel to create a smooth surface. Brooming creates a textured finish using a broom or brush. Stamping can mimic the appearance of other materials such as brick or stone by using patterned stamps. Polishing involves grinding and polishing the surface to achieve a glossy finish. The choice of finishing method will depend on factors such as aesthetics, slip resistance, and maintenance requirements.