The reasons for this differ from the point that the polished concrete floors require a great deal of technical information to the reality that many men and women prefer to imagine the whole process of improving the concrete floor as a procedure that's not suited to the daily woman. Combine this with concrete etching and also you can have a very artful look on your floors.

Here are Images about Concrete Floor Thickness Industrial

Concrete Floor Thickness Industrial

The main cause is that these floors are high efficiency flooring options and can last for many years. The toughest thing is waiting: Once the entire concrete floor is done, you still must hold off auto parking the automobile on it for another 72 hours. But there are concrete floors which seem plain and gray just love those present in factories and garages.

Concrete Floor Slabs Concrete Construction Magazine

In addition to this, among the best qualities of concrete flooring is its trouble free cleaning feature in which the particles of dust can be mopped. Even though many don't think about a concrete floor in their home for the fear of it being very cold, the opposite is in fact correct. For daily regimen, a soft broom or dust mop is effective.

Images Related to Concrete Floor Thickness Industrial

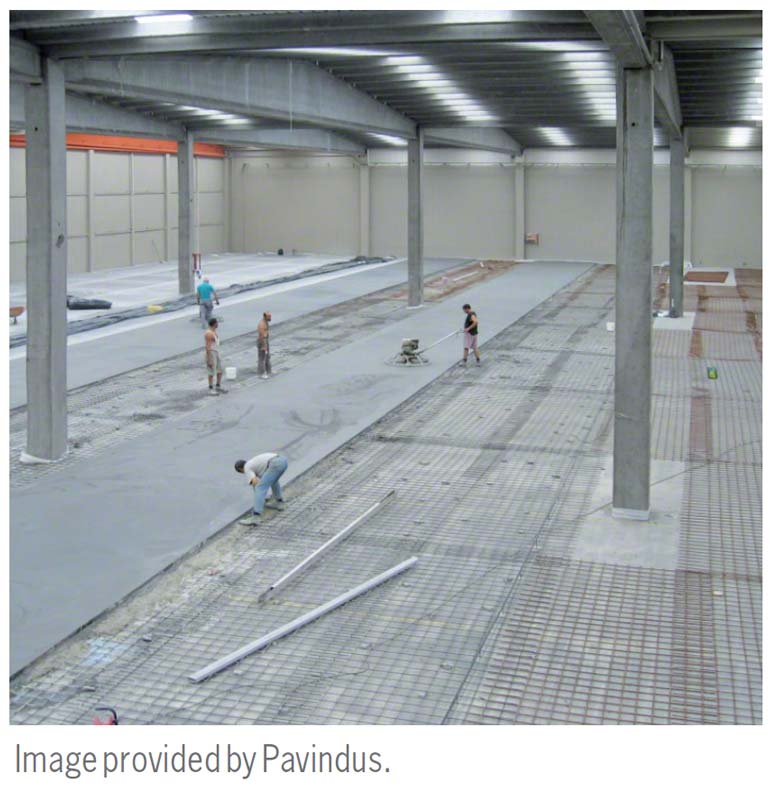

How to Design an Ideal Floor for Warehouse and Logistics Facilities

Concrete Floor Thickness for Heavy Equipment – Hansen Buildings

How are concrete slabs of varying degrees of thickness used in

Lightweight Concrete Floor Systems – Thickness, Uses – The Constructor

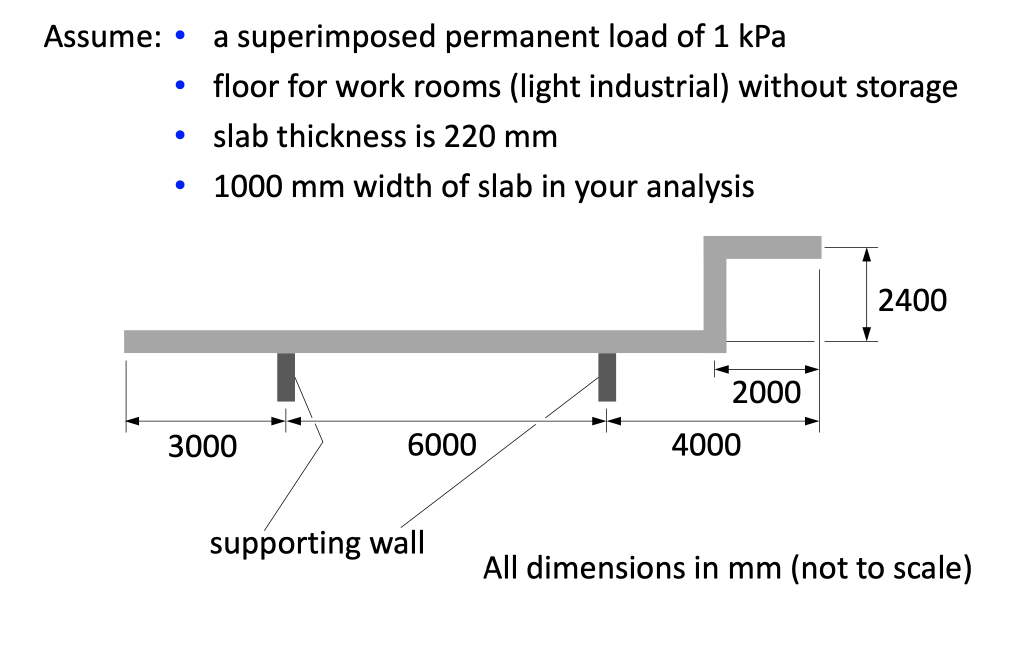

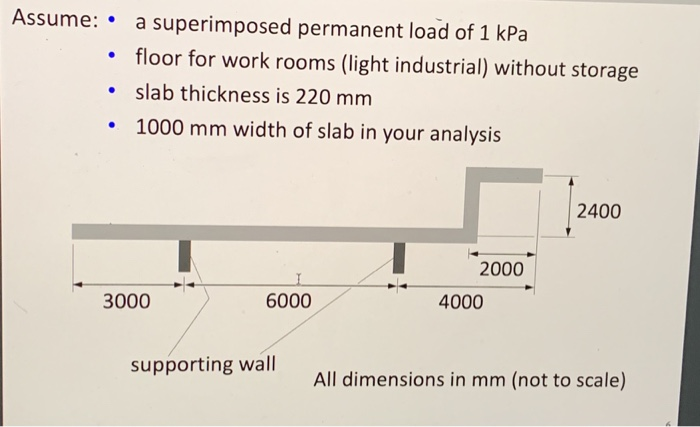

Consider the stepped concrete floor structure shown Chegg.com

Concrete Slab on Grade Analysis Calculator (for Post or Wheel Loading)

Warehouse flooring – Interlake Mecalux

Concrete: Slab Thickness » Alpha Paving

How are concrete slabs of varying degrees of thickness used in

Solved Consider the stepped concrete floor structure shown Chegg.com

Concrete Slab on Grade Thickness Analysis

Minimum Thickness of Concrete Elements Heaton Manufacturing

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Concrete floors are a common feature in industrial settings due to their durability, strength, and versatility. When it comes to constructing concrete floors for industrial use, one of the key considerations is the thickness of the concrete. The thickness of a concrete floor in an industrial setting plays a crucial role in determining its strength, durability, and ability to withstand heavy loads and high traffic. In this article, we will explore the importance of concrete floor thickness in industrial applications, along with the factors that influence it and the recommended thickness for different types of industrial facilities.

Importance of Concrete Floor Thickness in Industrial Settings

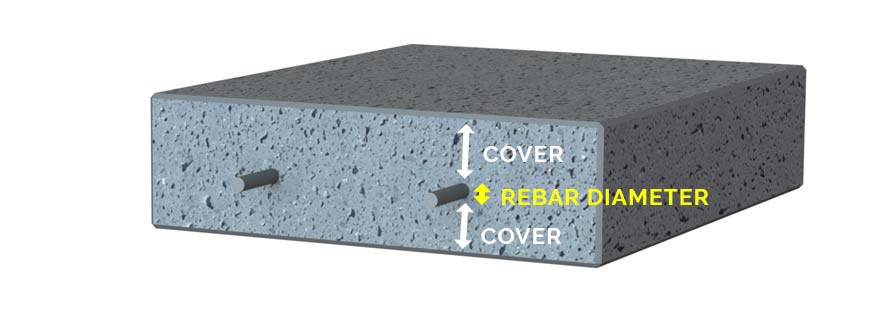

The thickness of a concrete floor in an industrial setting is essential for several reasons. Firstly, it determines the load-bearing capacity of the floor. A thicker concrete floor can support heavier loads without cracking or breaking under pressure. This is particularly important in industrial facilities where heavy machinery, equipment, and vehicles are commonly used.

Additionally, the thickness of a concrete floor affects its durability and resistance to wear and tear. Thicker concrete floors are more resistant to damage from impact, abrasion, and chemical exposure, making them ideal for industrial environments where these factors are prevalent.

Furthermore, the thickness of a concrete floor also influences its thermal properties. Thicker concrete floors have better thermal conductivity and can help regulate indoor temperatures in industrial facilities, reducing energy costs associated with heating and cooling.

Factors Influencing Concrete Floor Thickness

Several factors influence the thickness of a concrete floor in an industrial setting. One of the primary considerations is the type of loads that the floor will be subjected to. Heavy machinery, equipment, and vehicles require thicker concrete floors to ensure structural integrity and long-term performance.

The subgrade conditions also play a crucial role in determining the thickness of a concrete floor. Poor soil quality or unstable subgrade may require a thicker concrete slab to distribute loads evenly and prevent settling or cracking over time.

The intended use of the industrial facility is another factor that influences concrete floor thickness. High-traffic areas such as warehouses, distribution centers, and manufacturing plants may require thicker concrete floors to withstand constant wear and tear.

Recommended Concrete Floor Thickness for Different Types of Industrial Facilities

The recommended thickness of a concrete floor in an industrial setting varies depending on the specific requirements of the facility. However, there are some general guidelines that can help determine the appropriate thickness for different types of industrial facilities.

For light-duty industrial facilities such as storage areas or workshops where foot traffic or light vehicle traffic is expected, a minimum thickness of 4 inches is typically sufficient. This thickness provides adequate strength and durability for these types of applications.

For medium-duty industrial facilities such as warehouses or distribution centers where moderate vehicle traffic and heavy loads are common, a minimum thickness of 6 inches is recommended. This thicker slab can withstand heavier loads without compromising structural integrity.

For heavy-duty industrial facilities such as manufacturing plants or loading docks where heavy machinery and vehicles operate regularly, a minimum thickness of 8 inches or more may be required. Thicker slabs provide maximum strength and durability to support heavy loads and high traffic levels.

FAQs about Concrete Floor Thickness in Industrial Settings

Q: How do I determine the appropriate thickness for my industrial facility’s concrete floor?

A: The appropriate thickness for your facility’s concrete floor depends on factors such as the type of loads it will be subjected to, subgrade conditions, and intended use. Consulting with a structural engineer or concrete contractor can help determine the optimal thickness based on these factors.

Q: Can I use a thinner concrete slab to save Costs in my industrial facility?

A: While using a thinner concrete slab may initially save costs, it can lead to structural issues and maintenance problems in the long run. It’s important to choose the appropriate thickness based on the specific requirements of your facility to ensure durability and longevity.

Q: What is the importance of proper subgrade preparation for concrete floor thickness?

A: Proper subgrade preparation is crucial for ensuring the stability and longevity of a concrete floor. A stable subgrade helps distribute loads evenly and prevents settling or cracking, which can impact the performance of the concrete slab over time. Investing in proper subgrade preparation can help avoid costly repairs and maintenance in the future.

Q: How often should I inspect my industrial facility’s concrete floor for signs of wear and tear?

A: It’s recommended to inspect your industrial facility’s concrete floor regularly, at least once a year, to check for any signs of wear and tear such as cracks, spalling, or uneven surfaces. Addressing any issues promptly can help prevent further damage and extend the lifespan of the concrete floor.

Q: Are there any additional factors to consider when determining the thickness of a concrete floor in an industrial setting?

A: Yes, in addition to the type of loads and traffic expected, factors such as temperature fluctuations, exposure to chemicals or abrasives, and the presence of heavy equipment should also be taken into account when determining the appropriate thickness for a concrete floor in an industrial setting. These factors can impact the overall durability and performance of the concrete slab.

Q: What are some common maintenance practices for industrial concrete floors?

A: Some common maintenance practices for industrial concrete floors include regular cleaning to remove debris and contaminants, sealing or coating to protect against stains and wear, and repairing any cracks or damage promptly. Additionally, conducting regular inspections and addressing any issues as they arise can help prolong the lifespan of the concrete floor.

Q: Can I retrofit an existing concrete floor to increase its thickness for heavier loads?

A: In some cases, it may be possible to retrofit an existing concrete floor by adding a topping slab or overlay to increase its thickness and load-bearing capacity. However, this process can be complex and costly, so it’s important to consult with a structural engineer or concrete contractor to determine the feasibility and potential impact on the overall structure.

By considering these factors and consulting with professionals as needed, industrial facility owners can ensure that their concrete floors are properly designed and constructed to meet the specific requirements of their operations. Proper maintenance practices can further extend the lifespan of these floors and minimize the need for costly repairs in the future.