The polished floors are actually possibly the best methods to preserve the right floor while in maintaining with' green' observance simply because concrete flooring doesn't require inclusion of other raw materials or maybe substances, which would otherwise put a strain on the environment. Alternatively, concrete pulls the heat coming from the sun at the winter season, therefore your flooring stays warm.

Here are Images about Concrete Floor Slab Section

Concrete Floor Slab Section

Sealants, such as a polymer flooring seal, offer advantages that are numerous to interior and exterior flooring surfaces and are a very good addition to a concrete floors maintenance system. Caring for the decorative concrete floors of yours is not much different than the normal upkeep you do in just about any aspect of the home of yours.

Building Guidelines Drawings. Section B: Concrete Construction

When it comes to floor surfaces, polished concrete floors are materials which are great, which are much more ordinarily used. The fact is: concrete comes pre-installed in many homes, because the majority of houses are built on concrete slabs. The time it takes to complete the installation of a concrete floor is depending on how big and small the floor area is actually.

Images Related to Concrete Floor Slab Section

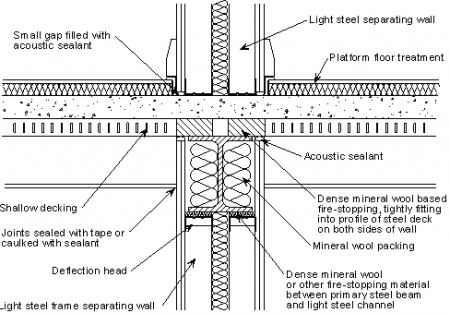

Floor systems – SteelConstruction.info

PDH Quiz – Guide for Concrete Floor and Slab Construction

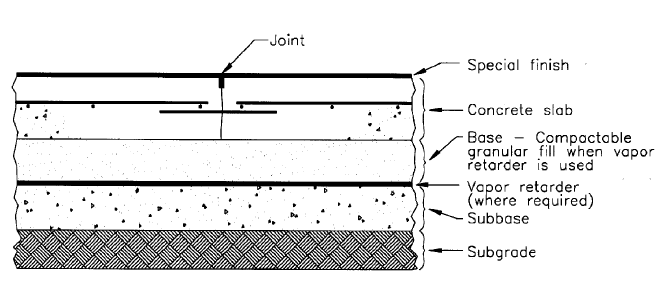

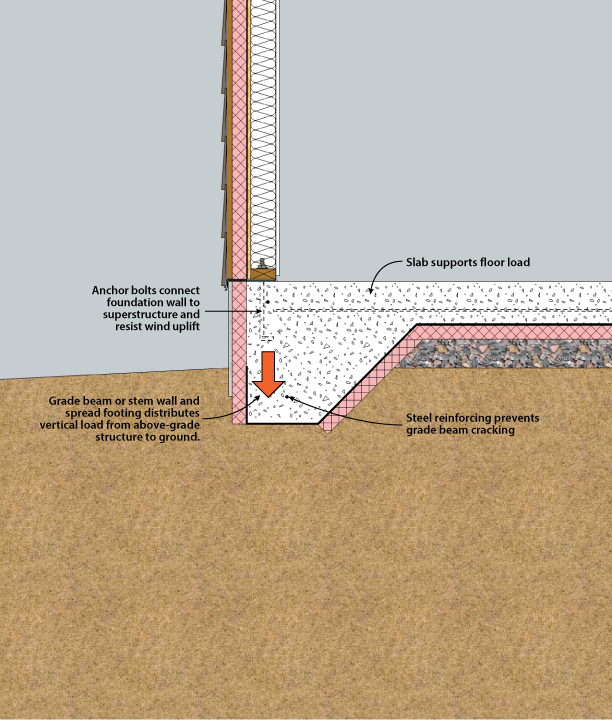

Figure B-10. Figure B-10: Alternative Floor Slab Detail. The

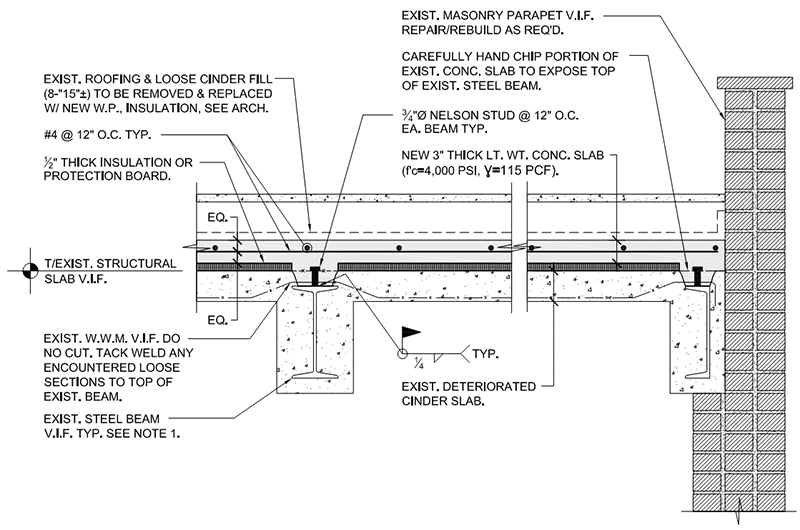

Second Floor Concrete Slab Wall Section Detail: Wall section

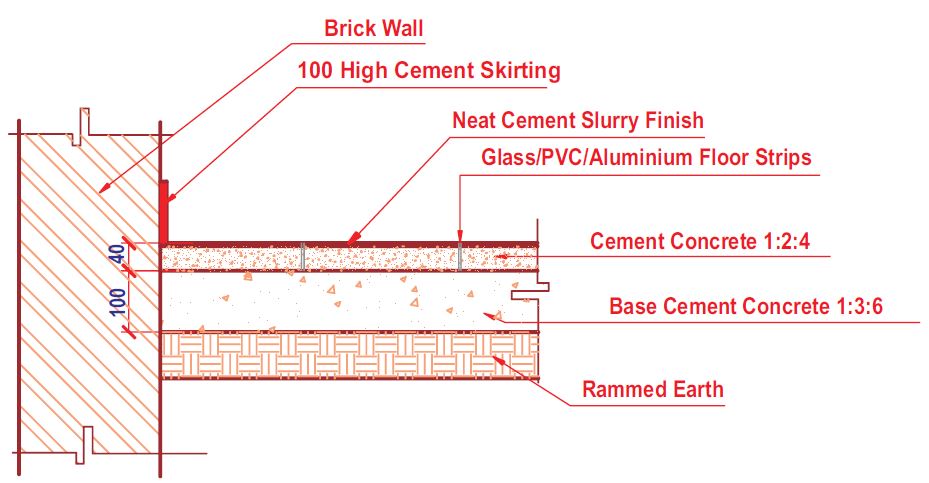

HOW TO CONSTRUCT CEMENT CONCRETE FLOOR? – CivilBlog.Org

Installing a Concrete Slab the Right Way – GreenBuildingAdvisor

Best Flooring for Concrete Slabs 50 Floor

DOE Building Foundations Section 4-1

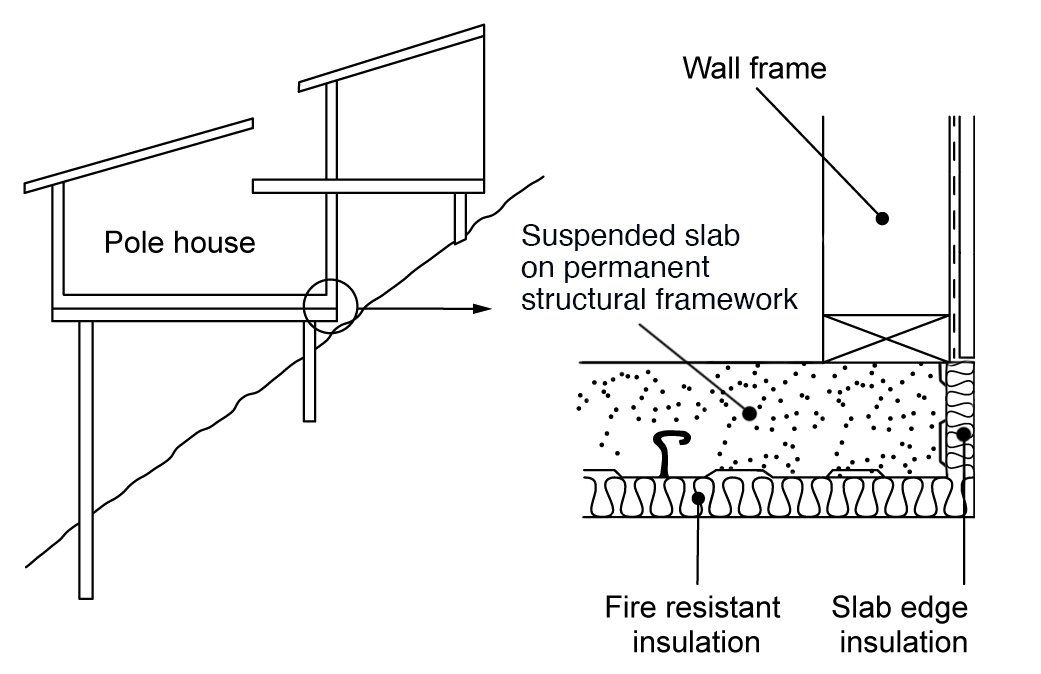

11-Construction detail of the concrete slab-on-ground floored case

STRUCTURE magazine Cinder Concrete Slab Construction

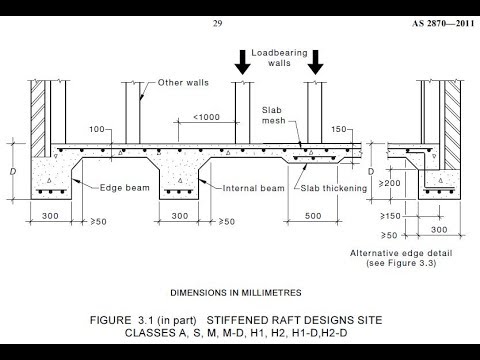

Concrete slab floors YourHome

Basic u0026 Easy How to draw a concrete slab section detail in AutoCAD Tutorial

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

A concrete floor slab section is a critical component of any building structure, providing a solid foundation for the rest of the construction. This section serves as the base upon which the entire building rests, supporting the weight of walls, floors, and occupants. In this article, we will explore the various aspects of a concrete floor slab section, including its components, construction process, maintenance requirements, and common issues.

Components of a Concrete Floor Slab Section

The concrete floor slab section consists of several key components that work together to create a strong and durable foundation. These components include:

1. Concrete Mix: The primary material used in constructing a concrete floor slab section is the concrete mix itself. This mix typically consists of cement, water, aggregate (such as sand or gravel), and additives (such as admixtures or fibers) to enhance strength and durability.

2. Reinforcement: To further strengthen the concrete slab and prevent cracking, reinforcement materials such as steel rebar or wire mesh are often added to the mix. These materials help distribute loads evenly across the slab and provide additional support.

3. Vapor Barrier: A vapor barrier is a crucial component of a concrete floor slab section, as it helps prevent moisture from seeping up through the slab. This barrier typically consists of a plastic sheeting material that is placed between the subgrade and the concrete mix.

4. Subgrade: The subgrade refers to the compacted soil or gravel layer on which the concrete slab is poured. It plays a vital role in providing a stable base for the slab and preventing settling or shifting over time.

Construction Process of a Concrete Floor Slab Section

The construction process of a concrete floor slab section involves several steps to ensure proper installation and long-term durability. These steps typically include:

1. Site Preparation: Before pouring the concrete mix, the site must be properly prepared by clearing debris, leveling the subgrade, and compacting it to prevent settling. Any necessary forms or molds are also set up at this stage.

2. Installation of Vapor Barrier: Once the site is prepared, a vapor barrier is laid down to prevent moisture penetration into the concrete slab. This barrier is essential for maintaining the integrity of the slab over time.

3. Reinforcement Placement: If reinforcement materials such as rebar or wire mesh are required, they are placed within the formwork before pouring the concrete mix. These materials help strengthen the slab and minimize cracking.

4. Pouring and Leveling Concrete Mix: The next step involves pouring the prepared concrete mix into the formwork and leveling it to create a smooth and even surface. Care must be taken to ensure proper thickness and consistency throughout.

5. Finishing: After the concrete mix has been poured and leveled, finishing techniques such as troweling or stamping may be used to achieve desired textures or patterns on the surface of the slab.

Maintenance Requirements for a Concrete Floor Slab Section

Proper maintenance is essential for ensuring the longevity and performance of a concrete floor slab section. Some key maintenance requirements include:

1. Regular Cleaning: Keeping the surface of the concrete slab clean by sweeping or mopping regularly helps prevent dirt buildup and staining over time.

2. Sealing: Applying a sealant to the surface of the concrete can help protect it from moisture infiltration, staining, and wear-and-tear caused by foot traffic or vehicles.

3. Repairing Cracks: Cracks in a concrete floor slab should be repaired promptly to prevent water penetration and further deterioration. Epo Xy or concrete patching materials can be used to fill in cracks and prevent them from expanding.

4. Monitoring Drainage: Ensuring proper drainage around the concrete slab is important to prevent water from pooling and causing damage. Clearing debris from drains and gutters regularly can help maintain good drainage.

5. Inspections: Regular inspections of the concrete floor slab section for signs of damage, cracking, or settling can help identify issues early on and prevent costly repairs in the future. If any issues are detected, they should be addressed promptly by a professional.

By following these construction and maintenance guidelines, you can ensure that your concrete floor slab section remains durable and functional for many years to come. Proper installation, maintenance, and repairs as needed will help extend the lifespan of your concrete slab and keep it looking its best. Additionally, it is important to avoid using harsh chemicals or abrasive cleaning tools on the surface of the concrete slab, as these can cause damage and deterioration over time. Using a pH-neutral cleaner and gentle scrubbing tools is recommended for regular maintenance.

Lastly, it is important to address any issues with the concrete slab promptly to prevent further damage and ensure the structural integrity of the floor. Consulting with a professional contractor for any repairs or maintenance needs is advisable to ensure that the work is done correctly and effectively. By following these maintenance requirements, you can help prolong the lifespan of your concrete floor slab section and keep it in optimal condition for years to come.