The polished concrete is a fast printer becoming a common problem in many places across the environment and this's mainly because a lot of people are appreciative of the beauty of its and also since many places only are not able to stand having other kind of floor. Sealed concrete has an extremely low environmental impact.

Here are Images about Concrete Floor Sealing Systems

Concrete Floor Sealing Systems

Staining is probably the most common method applied to concrete flooring, acid stains are directly applied to the floor to develop strong rich colours. Polished concrete flooring comes with a slew of advantages to home builders and renovators. You are able to make several geometric shapes and designs to form essentially a patent that you want. The natural color proficiency of concrete will accentuate any color scheme.

Garage Floor Sealers Guide From Densifiers to Epoxy Coatings

Remember concrete flooring can be discussed with several substances like epoxy, a beautiful durable finish which can be used anywhere in the home. Concrete office flooring is a green choice that frequently outlasts various other floor varieties as carpet, tile, wood, and linoleum.

Images Related to Concrete Floor Sealing Systems

concrete floor coating systems Archives – CoverTec Products

Concrete Floor Coating Maintenance and Sustainability Basement

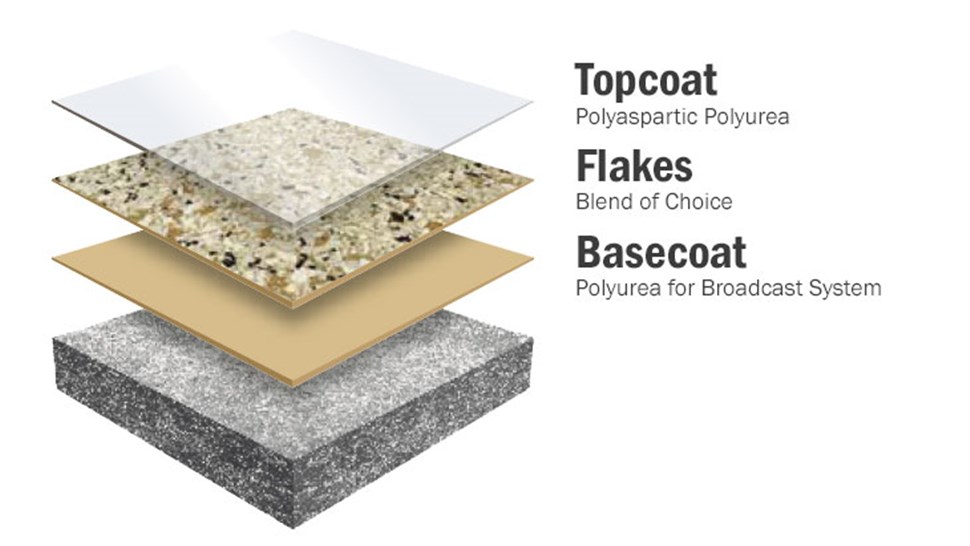

Chip Systems Garage Floor Coating Rasmusen

All About Full-Flake Concrete Coating Systems – Schilling Group

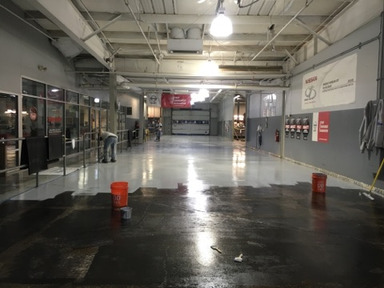

sealing concrete floor of shop

Introducing StoneTuff™ Concrete Floor Coating Systems

Concrete Floor Sealer – How to Seal Concrete Floors – Concrete Network

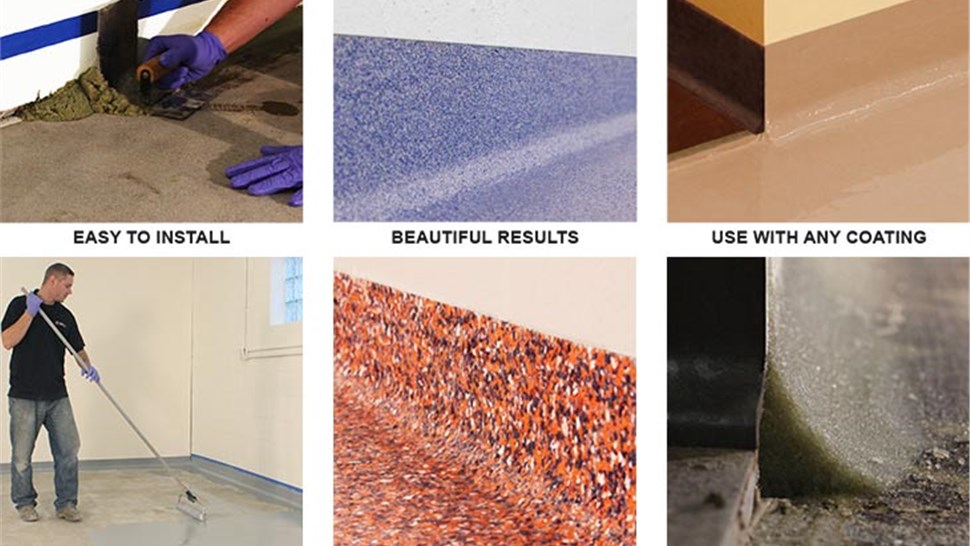

Formcove System Garage Floor Coating Rasmusen

Learn about the benefits of epoxy flooring, urethane topcoats

One Day Garage Floor Coating 24 hour Garage Concrete Coating

Expert Epoxy Floor Coating Installers in Indianapolis u0026 Beyond

Is Your Floor in Need of Concrete Floor Sealant?

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Concrete floor sealing systems are the perfect way to protect, strengthen, and extend the life of your concrete floors. Sealing concrete is an important step in maintaining the appearance and integrity of your flooring, however there are many different types of sealers available to choose from. This article will discuss the types of sealers available, their advantages and disadvantages, as well as some tips for proper application and maintenance.

Types of Concrete Floor Sealing Systems

There are several types of concrete floor sealing systems available. The most popular are epoxy, acrylic, and polyurethane sealants. Each one offers different levels of protection and durability, so it is important to choose the right one for your needs.

Epoxy Sealant

Epoxy sealant is a two-part liquid material that is mixed together and applied to the concrete in a thin layer. It is highly resistant to chemicals, UV radiation, and water damage. It is also very durable, making it ideal for high traffic areas such as garages or warehouses.

Acrylic Sealant

Acrylic sealant is a single-component liquid material that can be applied in a thin layer. It is highly resistant to abrasion, chemicals, and UV radiation. However, it is not as durable as epoxy sealants and may require more frequent reapplication.

Polyurethane Sealant

Polyurethane sealant is a two-part liquid material that is applied in a very thin layer. It is highly resistant to chemical deterioration, moisture, and UV radiation, making it ideal for outdoor applications. It can also provide a glossy finish that will enhance the look of any concrete surface.

Advantages & Disadvantages

Each type of sealer has its own advantages and disadvantages. Epoxy sealants offer the highest level of protection but can be difficult to apply correctly. Acrylic sealants are easier to apply but may require more frequent reapplication. Polyurethane sealants offer excellent protection and a glossy finish but can be more expensive than other options.

Application & Maintenance Tips

To ensure the best performance from your concrete floor sealing system, it is important to follow these tips:

• Always use the correct type of sealer for your application

• Prepare the surface properly before applying the sealer

• Follow directions carefully when mixing and applying the sealer

• Allow adequate drying time between coats

• Clean up spills immediately to prevent staining or discoloration

• Avoid using harsh chemicals or abrasive cleaners on sealed surfaces

• Reapply the sealer regularly according to manufacturer’s instructions

• Inspect the surface regularly for signs of wear or damage

Conclusion

Concrete floor sealing systems offer an effective way to protect and maintain your floors for years to come. By choosing the right type of sealer for your needs, following application instructions carefully, and performing regular maintenance, you can ensure that your floors will remain looking their best for years to come.