However, the problem with DIY flooring concreting is you might not have the means to mix an exact proportion for the cement and water blend and will result in a bad consequence. Concrete floors polishing is able to turn the surface into an elegant floor. Concrete flooring appears good of residences as it blends well with home furnishing.

Here are Images about Concrete Floor Screed Specification

Concrete Floor Screed Specification

You will find a few ways to approach cleaning concrete floor, depending on its look, whether it located inside or maybe outside, whether or not the concrete has been sealed and its present state of cleanliness. Polished concrete floors these days has been just about the most popular options in most home as well as business constructions.

A BSBG guide to floor screeds Brewer Smith Brewer Group

They are generally resilient to injury, simple to keep and very simple to clean. While a number of people like to use granite or slate for flooring surfaces, concrete floor is equally as gorgeous and a lot less costly. When cleaning polished concrete floors, you don't need to rely on harsh chemical cleaners anymore.

Images Related to Concrete Floor Screed Specification

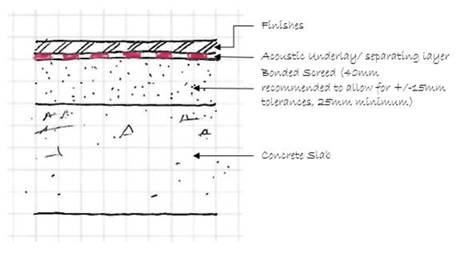

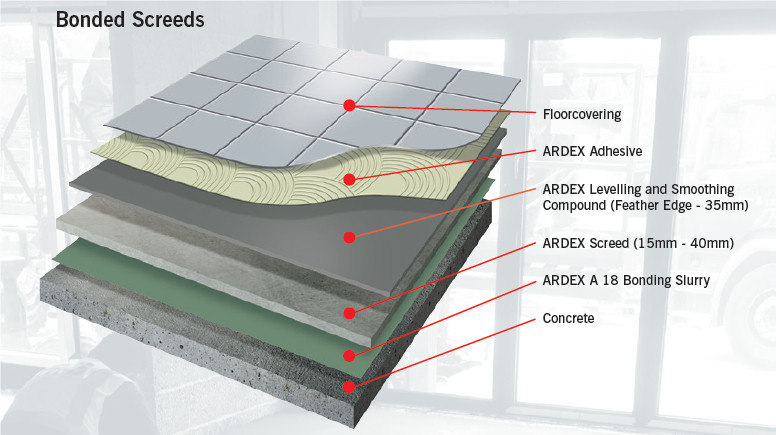

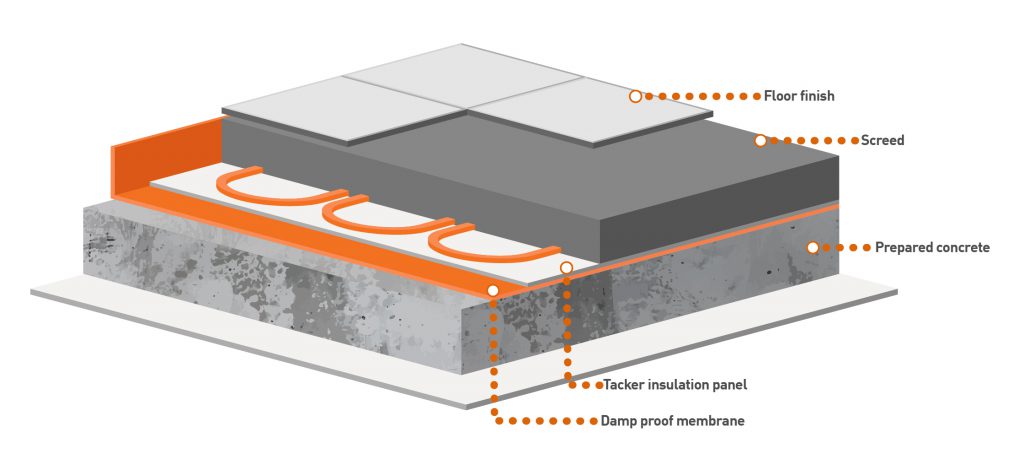

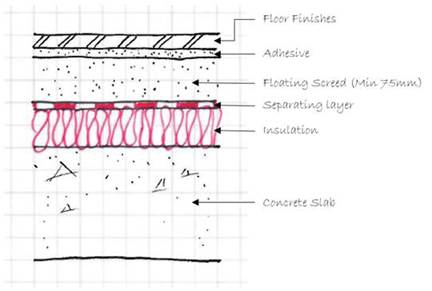

Types of Screed Bonded Screed Unbonded Screed Floating Screed

Floor Screeds for Under Floor Heating and Floor Levelling Compound

Some information about Floor Screed

What is Screed? EasyMix Concrete UK Ltd

A BSBG guide to floor screeds Brewer Smith Brewer Group

Floor Screeding Lesson no ppt video online download

Types of Screed Bonded Screed Unbonded Screed Floating Screed

Flowing Screeds How it works EJS Floor Solutions

Technical – Flowing Screeds – Flo Screed Liquid Flooring

which minimum thickness floor screed can be used in apartment

Concrete Screed Minimum Thickness?

Liquid Floor Screeds In Northern Ireland Alpha Flow Screeds

Related articles:

- Concrete Floor Inside House

- Leveling Old Concrete Floor

- Smooth Concrete Floor Finish

- Concrete Floor Heating Installation

- Polished Concrete Floor Over Wood Subfloor

- How To Pour A Concrete Floor Over A Basement

- Concrete Floor Cleaning Machines For Rent

- Best Epoxy Concrete Floor Paint

- Concrete Floor Interior House

- Concrete Flooring Pretoria

Concrete floor screed is a vital component in the construction of floors in various buildings, including residential, commercial, and industrial spaces. It serves as a level surface for the final flooring material to be installed on top of it. The specification of concrete floor screed is crucial to ensure its durability, strength, and performance over time. In this article, we will discuss the detailed specifications of concrete floor screed, including materials used, thickness requirements, mixing ratios, application methods, and quality control measures.

Materials Used for Concrete Floor Screed

One of the most critical aspects of specifying concrete floor screed is selecting the right materials. The primary components of concrete floor screed include cement, sand, and water. Portland cement is commonly used in screed mixes due to its high strength and durability. The sand used should be clean, well-graded, and free from impurities to ensure a smooth finish. Water is added to the mix to achieve the desired consistency for easy application.

FAQs:

Q: Can I use any type of cement for concrete floor screed?

A: Portland cement is the most suitable type of cement for concrete floor screed due to its high strength and durability.

Q: What type of sand should I use for concrete floor screed?

A: Clean, well-graded sand free from impurities is recommended for use in concrete floor screed mixes.

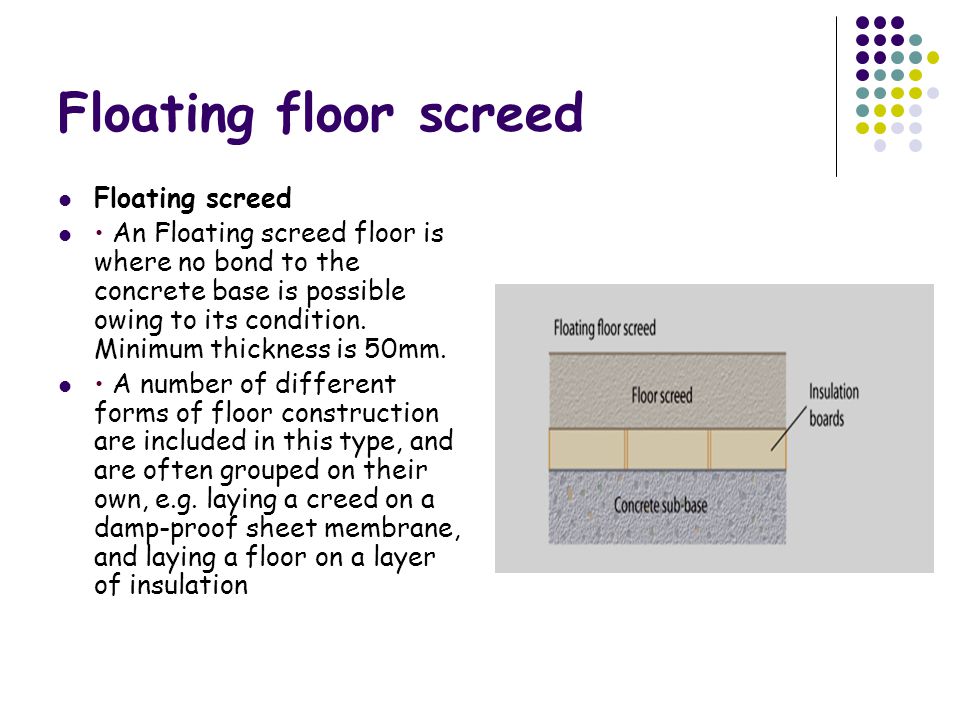

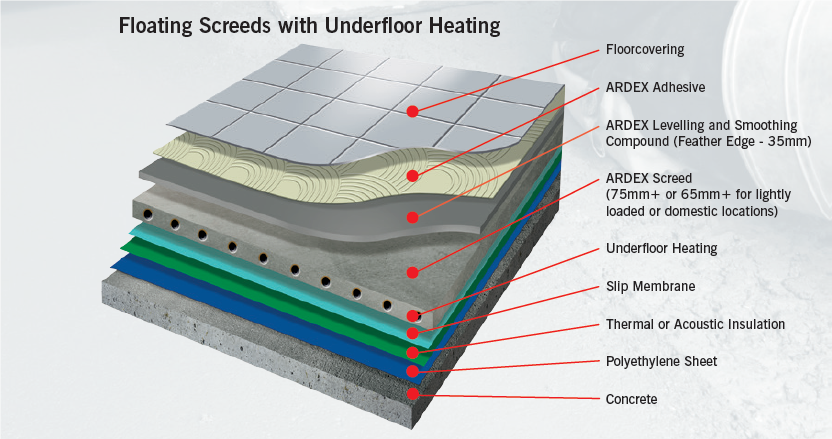

Thickness Requirements for Concrete Floor Screed

The thickness of concrete floor screed plays a crucial role in determining its strength and durability. The minimum thickness required for most applications is typically around 50mm to 75mm. However, in heavy-duty industrial settings or areas with high traffic loads, a thicker screed may be necessary to withstand the additional stress. It is essential to consult with structural engineers or contractors to determine the appropriate thickness for your specific project requirements.

FAQs:

Q: What is the minimum thickness required for concrete floor screed?

A: The minimum thickness for most applications is typically around 50mm to 75mm.

Q: Do I need a thicker screed for heavy-duty industrial settings?

A: Yes, in heavy-duty industrial settings or areas with high traffic loads, a thicker screed may be necessary to withstand additional stress.

Mixing Ratios for Concrete Floor Screed

The mixing ratio of materials plays a significant role in determining the strength and consistency of concrete floor screed. A typical mix ratio for concrete floor screed is 1 part cement to 3-5 parts sand by volume. Water is added gradually while mixing until the desired consistency is achieved. It is essential to follow manufacturer guidelines and specifications when mixing concrete floor screed to ensure optimal performance and durability.

FAQs:

Q: What is the typical mix ratio for concrete floor screed?

A: A typical mix ratio is 1 part cement to 3-5 parts sand by volume.

Q: How much water should I add when mixing concrete floor screed?

A: Water should be added gradually while mixing until the desired consistency is achieved.

Application Methods for Concrete Floor Screed

There are several methods available for applying concrete floor screed, including traditional hand-applied methods and modern pump application techniques. Hand application involves spreading the mixed screed manually using trowels or floats to achieve a smooth finish. Pump application methods use specialized equipment to pump the mixed screed onto the substrate quickly and efficiently. The choice of application method depends on factors such as project size, complexity, and accessibility.

FAQ S:

Q: What are the different methods for applying concrete floor screed?

A: The methods include traditional hand-applied methods and modern pump application techniques.

Q: How do I choose the best application method for my project?

A: Factors such as project size, complexity, and accessibility should be considered when choosing an application method for concrete floor screed.

Maintenance and Care for Concrete Floor Screed

Proper maintenance and care are essential for ensuring the longevity and performance of concrete floor screed. Regular cleaning with a mild detergent and water can help remove dirt, grime, and stains from the surface. Avoid using harsh chemicals or abrasive cleaners, as these can damage the screed. It is also important to promptly repair any cracks or damage to prevent further deterioration. Additionally, applying a sealant or coating can help protect the surface from wear and tear, making it easier to clean and maintain over time.

FAQs:

Q: How should I clean concrete floor screed?

A: Use a mild detergent and water to clean the surface of concrete floor screed. Avoid harsh chemicals or abrasive cleaners.

Q: What should I do if I notice cracks or damage on the surface?

A: Promptly repair any cracks or damage on the surface of concrete floor screed to prevent further deterioration.

In conclusion, concrete floor screed is a versatile and durable material that is commonly used in a variety of construction projects. By understanding key factors such as thickness requirements, mixing ratios, application methods, and maintenance tips, you can ensure the successful installation and long-term performance of concrete floor screed in your project. Consulting with professionals and following manufacturer guidelines will help you achieve optimal results for your specific application.