Polished concrete flooring can be the first step toward establishing an allergy free setting. Polished concrete is becoming a favorite office floor choice due to its durability, simple upkeep, and sizable selection of colors and decorative options. You can further mop it using hot, soapy water, but only using a light detergent.

Here are Images about Concrete Floor Polishing Process

Concrete Floor Polishing Process

Working together with polished concrete floors is something that most men and women may not be well clued all about. Do you have polished concrete floors, or perhaps perhaps terrazzo floors? This makes knowing what sort of paint to go with rather easy. Dust, dust and dander mites can all be stopped by using this sort of flooring.

Polished Concrete Guide

The mantra is to cover the current concrete floor with a thin cement-based overlay to create a fresh brand new picture to concentrate on. Once they've cured, new concrete installations are inexpensively and easily brought to a shine. When putting in polished concrete flooring surfaces, the concrete is actually sanded with a diamond surfaced polishing machine.

Images Related to Concrete Floor Polishing Process

Polished Concrete Floors (Benefits, Applications u0026 Maintenance)

The Preferred Polishing Process Preferred Concrete Polishing

Which Concrete Polishing Process is Right for Your Job – Concrete

Polished Concrete Process – Steps for Polishing Floors – Concrete

The Concrete Polishing Process, How to Polish Concrete

How To Polish Concrete – A Comprehensive Guide

How To Diamond Grind A Concrete Floor

Mechanical vs. Topical Polished Concrete, How to Polish Concrete

Concrete Floor Grinder For Sale Concrete grinder, Concrete

Polished concrete – Wikipedia

K u0026 J Concrete Polishing, Inc.

How to polish concrete floors – Quora

Related articles:

- Concrete Floor Joist System

- Best Concrete Floor Leveler

- Concrete Floor With Wood Inlay

- How To Lay Porcelain Tiles On A Concrete Floor

- Faux Stained Concrete Floors

- 1 Part Epoxy Concrete Floor Paint

- How To Paint Or Stain Concrete Floors

- Concrete Floor Sanding Pads

- Removing Mold From Concrete Floor

- Laying A Concrete Floor Slab

Concrete floor polishing is a popular method used to enhance the appearance and durability of concrete surfaces. Whether in residential, commercial, or industrial settings, polished concrete floors offer a sleek and modern look that is easy to maintain and long-lasting. In this article, we will delve into the concrete floor polishing process, outlining each step in detail to help you understand how this transformative technique can elevate your space.

1. Surface Preparation:

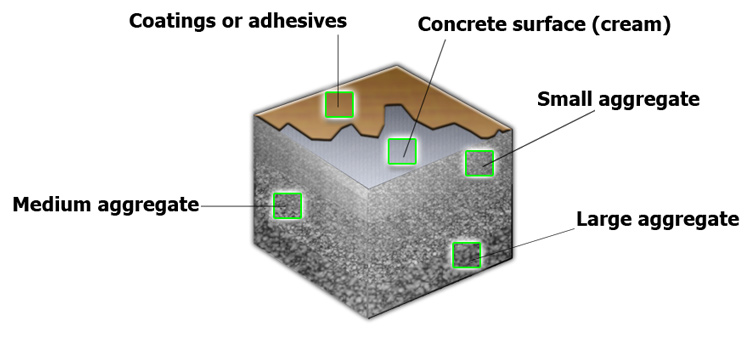

The first step in the concrete floor polishing process is surface preparation. This involves removing any existing coatings, adhesives, or contaminants from the concrete surface to ensure a clean and smooth substrate for polishing. Diamond grinding or shot blasting are commonly used methods to achieve this. Diamond grinding involves using diamond-tipped tools to grind away the top layer of concrete, while shot blasting uses small metal beads to blast away surface imperfections.

FAQs:

Q: Why is surface preparation important before polishing a concrete floor?

A: Surface preparation is essential to ensure proper adhesion of the polishing materials to the concrete surface. It also helps to remove any imperfections that could affect the final result of the polishing process.

2. Grinding and Leveling:

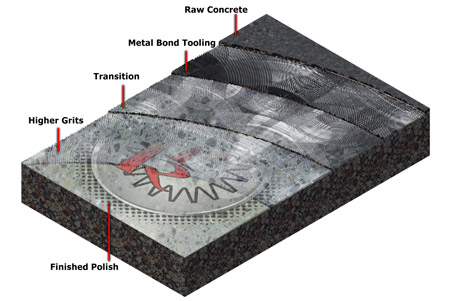

Once the surface is prepared, the next step is grinding and leveling the concrete floor. This involves using progressively finer grits of diamond tools to grind down the surface and level any uneven areas. The grinding process creates a smooth and uniform surface ready for polishing.

FAQs:

Q: How long does the grinding and leveling process take?

A: The time it takes to grind and level a concrete floor depends on the size of the area and the condition of the surface. It can range from a few hours to several days for larger projects.

3. Polishing:

After grinding and leveling the concrete floor, the polishing process begins. This step involves using progressively finer grits of diamond abrasives to achieve a high-gloss finish. The diamonds are embedded in resin pads that are attached to a polishing machine which rotates at high speeds to create friction and polish the surface.

FAQs:

Q: How many grit levels are typically used in the polishing process?

A: The polishing process typically starts with 100 grit diamond abrasives and progresses up to 3000 grit for a high-gloss finish. Some projects may require additional levels of grit depending on the desired outcome.

4. Densifying and Sealing:

Once the desired level of polish is achieved, densifying and sealing the concrete floor is essential to enhance its durability and longevity. Densifiers are chemical solutions that penetrate into the concrete pores, reacting with calcium hydroxide to create a denser surface that resists staining and wear. Sealing helps protect the polished surface from spills, scratches, and UV damage.

FAQs:

Q: How often should a polished concrete floor be resealed?

A: It is recommended to reseal a polished concrete floor every 1-3 years depending on foot traffic and wear. Regular maintenance such as cleaning with pH-neutral cleaners can also help prolong the life of the sealer.

5. Maintenance:

Proper maintenance is key to preserving the beauty and functionality of polished concrete floors. Regular cleaning with a damp mop or neutral pH cleaner can help remove dirt and debris that can dull the shine over time. Avoid using harsh chemicals or abrasive cleaners that can damage the sealer and polish.

FAQs:

Q: Can polished concrete floors be waxed for additional shine?

A: Waxing is not recommended for polished concrete floors as it can create a Buildup that may detract from the natural shine of the surface. Instead, regular cleaning and resealing as needed is sufficient to maintain the polished finish.

6. Cost:

Q: How much does it cost to polish a concrete floor?

A: The cost of polishing a concrete floor can vary depending on factors such as the size of the area, the condition of the concrete, and the level of gloss desired. On average, the cost can range from $3 to $12 per square foot. It is best to get a quote from a professional contractor to determine the exact cost for your project.

7. Eco-Friendly Option:

Q: Is polished concrete a sustainable flooring option?

A: Yes, polished concrete is considered a sustainable flooring option as it utilizes an existing material (concrete) without the need for additional resources. It also reduces the need for harsh chemicals for cleaning and maintenance, making it an eco-friendly choice for commercial and residential spaces.

8. Customization:

Q: Can polished concrete floors be customized with colors or designs?

A: Yes, polished concrete floors can be customized with a variety of options such as integral color dyes, decorative saw cuts, or stenciled patterns. These customization options can add a unique touch to your space and create a one-of-a-kind look that reflects your style and personality.

In conclusion, polished concrete floors are a durable, low-maintenance, and aesthetically pleasing flooring option for both residential and commercial spaces. By following proper installation and maintenance techniques, you can enjoy the benefits of polished concrete floors for years to come. If you have any additional questions or require further information, feel free to consult with a professional contractor who specializes in polished concrete flooring. Overall, polished concrete floors are a great choice for anyone looking for a modern and sustainable flooring option. With proper care and maintenance, they can last for many years while maintaining their shine and durability. If you are considering polished concrete floors for your space, be sure to consult with a professional contractor to discuss your options and get an accurate quote for your project. Whether you choose to customize your floors with unique designs or keep them simple and sleek, polished concrete floors are sure to add style and sophistication to any room.