The main concern for most customers for the substandard aesthetics, but presently polished concrete flooring truly stands out from the competitors for various reasons. These polishing compounds are actually sold in a great many shops as well as stores where similar items are sold and one may employ them to re instate the gleam on the polished concrete floors.

Here are Images about Concrete Floor On Ground

Concrete Floor On Ground

Polished concrete floors are now being noticed when the best subject matter which is both highly functional as well as decorative for public structures. You are able to blend it in other surfaces to compliment the flooring option of yours. Buyers usually have different preferences. The concept of a lifeless grey colored concrete flooring has been replaced with delightful surfaces that may look like granite, marble, and even tile.

Image result for concrete column to concrete ground floor

Remember concrete flooring may be discussed with several materials including epoxy, a lovely sturdy finish that can be used just about anywhere in the home. Concrete office flooring is a green colored option that usually outlasts other floor kinds like linoleum, wood, tile, and carpet.

Images Related to Concrete Floor On Ground

How is a ground floor slab constructed?

Ground level concrete slab subfloor BUILD

Concrete slab – Wikipedia

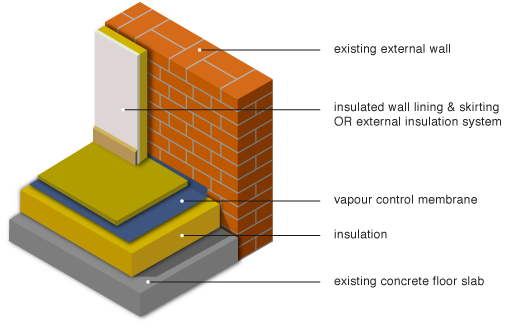

GreenSpec: Housing Retrofit: Ground Floor Insulation

How to Insulate a Concrete Floor Kingspan MEA u0026 India

Concrete slab floor construction BRANZ Renovate

What is the minimum depth for a concrete slab? – Quora

Concrete Ground Floor Slab Construction Steel Rebar, Power Floating, Floor Hardener by Power Trowel

Mix Design Fundamentals: Considerations for concrete for slabs-on

11-Construction detail of the concrete slab-on-ground floored case

Building Guidelines Concrete Floors, Slabs

Construction of Slabs on Ground -Design Considerations ACI and ASTM

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Concrete floors on the ground can provide a number of advantages for homeowners, from increased durability to cost savings. Installing these floors can be a relatively straightforward process with the right preparation and materials. Here is a comprehensive guide to help you get started.

Preparing for Installation

Before you begin installing concrete floors, there are several steps you must take to ensure that the job goes smoothly. First, you must prepare the area by clearing away any debris and removing any existing flooring material. Next, you will need to level the area with a concrete screed or other leveling material. Finally, you will need to install a vapor barrier underneath the new concrete floor to protect it from moisture.

Choosing Materials

When it comes to selecting materials for your concrete floor installation, there are several options available. For the most part, you will need some type of concrete mix, as well as tools and supplies like trowels, wheelbarrows, and vibrators. Additionally, you might consider using admixtures like plasticizers and water reducers to improve the performance of the concrete mix.

Laying the Slab

Once everything is set up and ready to go, it’s time to start laying down your concrete slab. First, mark out the area of your slab so that you can accurately measure and pour the concrete mix into place. Next, use a shovel or trowel to spread the concrete evenly over the surface and make sure it is level. Finally, use a vibrator to compact the concrete and remove any air pockets.

Curing Process

Once the concrete has been poured and leveled, it’s important to allow it to cure properly before using it. This curing process can take anywhere from two days to two weeks depending on temperature and humidity levels. During this time, ensure that the surface remains covered with a plastic sheet or tarp to protect it from rain or other environmental conditions. Additionally, keep in mind that if temperatures are too hot or cold during this process, they can affect how well the concrete cures.

Finishing Touches

Once your concrete floor has cured properly, it’s time to finish up with some finishing touches like sealing or staining. Sealing your concrete floor is important as it helps protect it from moisture damage over time. Additionally, staining your concrete is an easy way to add some visual appeal to your space while still maintaining its durability.

Common Questions & Answers

Q: What is the best way to prepare an area for a concrete floor installation?

A: The best way to prepare an area for a concrete floor installation is by clearing away any debris and removing any existing flooring material, leveling the area with a concrete screed or other leveling material, and installing a vapor barrier underneath the new concrete floor.

Q: How long does it take for a concrete floor to cure properly?

A: The curing process for a concrete floor can take anywhere from two days to two weeks depending on temperature and humidity levels. It is important to keep in mind that if temperatures are too hot or cold during this process, they can affect how well the concrete cures.

Q: What are some finishing touches I can add to my concrete floor?

A: Finishing touches such as sealing or staining your concrete floor can add some visual appeal while still maintaining its durability. Sealing helps protect it from moisture damage over time while staining adds color and texture variation.