The polished floors are among the best techniques to maintain a suitable floors while in trying to keep with' green' observance simply because concrete flooring does not require inclusion of other raw materials or substances, which would usually put a force on the planet. Alternatively, concrete pulls the heating coming from the sun in the winter months, therefore your flooring remains warm.

Here are Images about Concrete Floor Insulation Products

Concrete Floor Insulation Products

Working together with polished concrete floors is something which nearly all folks might not be well clued about. Do you have polished concrete floors, or maybe maybe terrazzo floors? This will make knowing what kind of paint to go with much easier. Dust, dust and dander mites can all be prevented by making use of this kind of flooring.

Lowe 4FSFB/SE400-T Under Concrete Foil Insulation Slab Radiant

A polished concrete floor doesn't need to have frequent cleaning, which means that you can clean them whenever or alternatively you are free. Concrete is very long-lasting and never has to be replaced though you could need to touch up the finish that's an inexpensive and easy pretty task. With all these advantages, one of the main advantages of concrete floors is the pricing of its.

Images Related to Concrete Floor Insulation Products

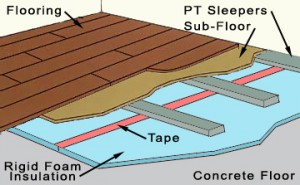

Installing Rigid Foam Above a Concrete Slab – GreenBuildingAdvisor

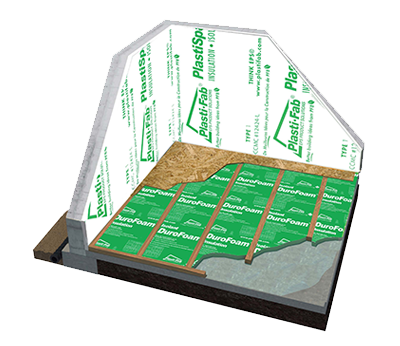

Under Concrete Insulation Application ESP Low-E Northeast

Ground floor – insulation below concrete slab – Polyfoam XPS

Advantage (ICFs) Insulating Concrete Forms u2013 Other Insulation

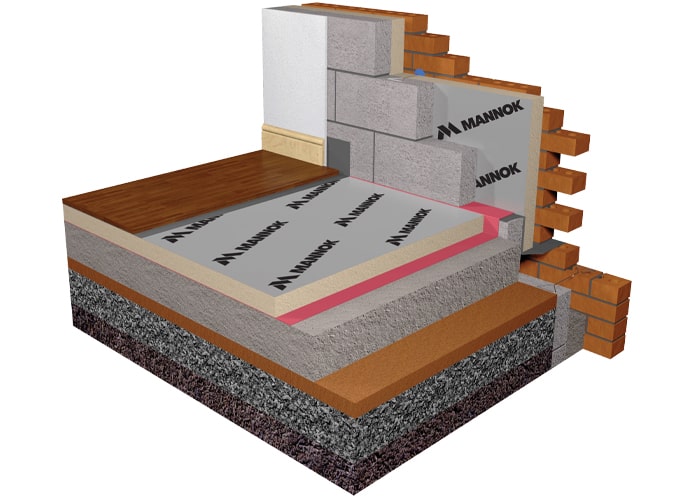

Floor Insulation – Mannok

Concrete Slab Insulation

5 Best Insulation Over Concrete Floor – Warm u0027Em Up! ToolzPick

Garage Retrofit with Insulated Concrete Floor

Insulating Over a Structural Slab JLC Online

In floor Heating Insulation-Under Floor Heating Insulation-Radiant

How (and Why) to Insulate a Concrete Floor BuildDirectLearning

The Best Moisture Barrier for Protecting Concrete Slabs and Floors

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Concrete Floor Insulation Products: Enhancing Energy Efficiency and Comfort

Introduction:

Insulating concrete floors is a crucial step in creating an energy-efficient and comfortable living or working space. Concrete floors are known for their durability and strength, but without proper insulation, they can become cold and uncomfortable, leading to higher energy bills. Thankfully, there are a variety of concrete floor insulation products available in the market today that can help improve thermal efficiency and provide a more comfortable environment. In this article, we will explore some of the most popular concrete floor insulation products, their benefits, and how they can be installed effectively.

1. Expanded Polystyrene (EPS) Insulation:

Expanded Polystyrene (EPS) insulation is one of the most commonly used products for insulating concrete floors. EPS insulation boards are lightweight yet strong, making them easy to handle and install. These boards have excellent thermal properties, providing an efficient barrier against heat loss. They are also resistant to moisture and do not degrade over time. EPS insulation boards are available in various thicknesses to suit different insulation requirements.

FAQs:

Q: How is EPS insulation installed under concrete floors?

A: EPS insulation boards are typically laid directly on top of the existing subfloor before pouring the concrete slab. The boards should be tightly fitted together, leaving no gaps for heat transfer.

Q: Can EPS insulation be used in both residential and commercial buildings?

A: Yes, EPS insulation is suitable for both residential and commercial applications. It is widely used in homes, offices, warehouses, and other structures.

2. Extruded Polystyrene (XPS) Insulation:

Extruded Polystyrene (XPS) insulation is another popular choice for insulating concrete floors. XPS insulation boards have a closed-cell structure, which gives them exceptional moisture resistance properties. They are highly rigid and durable, capable of withstanding heavy loads without compressing or losing their insulating properties. XPS insulation boards are available in various thicknesses, allowing for customization to meet specific insulation requirements.

FAQs:

Q: How does XPS insulation compare to EPS insulation?

A: While both EPS and XPS insulation offer excellent thermal performance, XPS insulation has a higher compressive strength and moisture resistance. This makes it particularly suitable for areas with high foot traffic or potential moisture exposure.

Q: Can XPS insulation be used in below-grade applications?

A: Yes, XPS insulation is commonly used in below-grade applications, such as basement floors, where moisture resistance is crucial.

3. Polyisocyanurate (PIR) Insulation:

Polyisocyanurate (PIR) insulation is a type of rigid foam board that offers exceptional thermal performance. PIR insulation boards have a high R-value per inch, meaning they provide efficient insulation with less material thickness compared to other products. They are lightweight, making them easy to handle during installation. PIR insulation is also resistant to moisture and fire, adding an extra layer of safety to the building.

FAQs:

Q: Is PIR insulation suitable for all types of concrete floors?

A: Yes, PIR insulation can be used in various concrete floor applications, including ground-bearing slabs, suspended floors, and beam and block systems.

Q: Can PIR insulation contribute to energy savings?

A: Absolutely! PIR insulation has excellent thermal properties that significantly reduce heat loss through concrete floors. This leads to lower energy consumption and reduced heating costs.

4. Cork Insulation: Cork insulation is another option for insulating concrete floors. Cork is a natural and sustainable material made from the bark of cork oak trees. Cork insulation boards are lightweight, easy to install, and have excellent thermal insulation properties. They also have good sound insulation capabilities, making them a popular choice for noise reduction in buildings. Cork insulation is resistant to moisture and mold growth, making it suitable for areas with high humidity or potential water exposure.

FAQs:

Q: Can cork insulation be used in both residential and commercial buildings?

A: Yes, cork insulation can be used in both residential and commercial applications. It is commonly used in homes, offices, schools, and other structures.

Q: How is cork insulation installed under concrete floors?

A: Cork insulation boards are typically glued or mechanically fastened to the subfloor before pouring the concrete slab. The boards should be tightly fitted together to ensure there are no gaps for heat transfer.

Overall, there are several options available for insulating concrete floors, including EPS, XPS, PIR, and cork insulation. Each type has its own unique properties and benefits, so it’s important to consider factors such as moisture resistance, compressive strength, thermal performance, and sustainability when choosing the right insulation material for your project. Some other commonly used insulation materials for concrete floors include expanded polystyrene (EPS) and extruded polystyrene (XPS) insulation. EPS insulation is a lightweight and cost-effective option that provides good thermal insulation. It is resistant to moisture and can be used in below-grade applications.

XPS insulation, on the other hand, offers higher compressive strength and better moisture resistance compared to EPS insulation. It is commonly used in below-grade applications, such as basement floors, where moisture resistance is crucial.

Polyisocyanurate (PIR) insulation is another type of rigid foam board that offers exceptional thermal performance. PIR insulation boards have a high R-value per inch, meaning they provide efficient insulation with less material thickness compared to other products. They are lightweight, easy to handle during installation, and resistant to moisture and fire.

Cork insulation is a natural and sustainable option made from the bark of cork oak trees. It is lightweight, easy to install, and has excellent thermal insulation properties. Cork insulation also has good sound insulation capabilities, making it popular for noise reduction in buildings. It is resistant to moisture and mold growth, making it suitable for areas with high humidity or potential water exposure.

When choosing the right insulation material for your project, it’s important to consider factors such as moisture resistance, compressive strength, thermal performance, and sustainability. Each type of insulation material has its own unique properties and benefits, so it’s important to evaluate your specific needs before making a decision. Some commonly used insulation materials for concrete floors include expanded polystyrene (EPS), extruded polystyrene (XPS), polyisocyanurate (PIR), and cork insulation. EPS insulation is lightweight, cost-effective, and resistant to moisture, making it suitable for below-grade applications. XPS insulation offers higher compressive strength and better moisture resistance, making it ideal for basement floors. PIR insulation provides exceptional thermal performance with a high R-value per inch and is resistant to moisture and fire. Cork insulation is a natural and sustainable option that is lightweight, easy to install, and has excellent thermal and sound insulation properties. It is also resistant to moisture and mold growth, making it suitable for areas with high humidity or potential water exposure. When choosing an insulation material, it’s important to consider factors such as moisture resistance, compressive strength, thermal performance, and sustainability to ensure the best fit for your project.