As soon as the concrete floor is clean and ready for the coating of its, it all comes down to timing. The floor at the medical center or maybe supermarket might look glossy, attractive and very unique; this is only since it is a polished concrete floor. Polished concrete flooring offers an excellent visual sight while maintaining a feeling of uniqueness and style about it.

Here are Images about Concrete Floor Fasteners

Concrete Floor Fasteners

But, it's critical for each home owner who's using the polished concrete floors to know the way the polished flooring is achieved when everything has been said and done. Acid Stain concrete floorings have a bit of time and once again proven the reliability of theirs in terms of cost efficiency, durability and the strength of the flooring.

The Best Concrete Anchors for Various Building Projects in 2022

If necessary, consider re-applying the sealant as this is going to go quite a distance to improving the longevity as well as appearance of the concrete floor. The initial step before considering some tips as well as tricks is figuring out what type of concrete you have. The latest technology to create the boring of yours and lackluster concrete flooring into a polished and shiny mirror.

Images Related to Concrete Floor Fasteners

A Beginneru0027s Guide to Attaching Things to Concrete and Brick

Best Cinder Block Fasteners – Concrete Fastening Systems, Inc.

How to Install Concrete Wedge Anchors

Concrete Fasteners

Drilling Concrete and Installing Fasteners Family Handyman

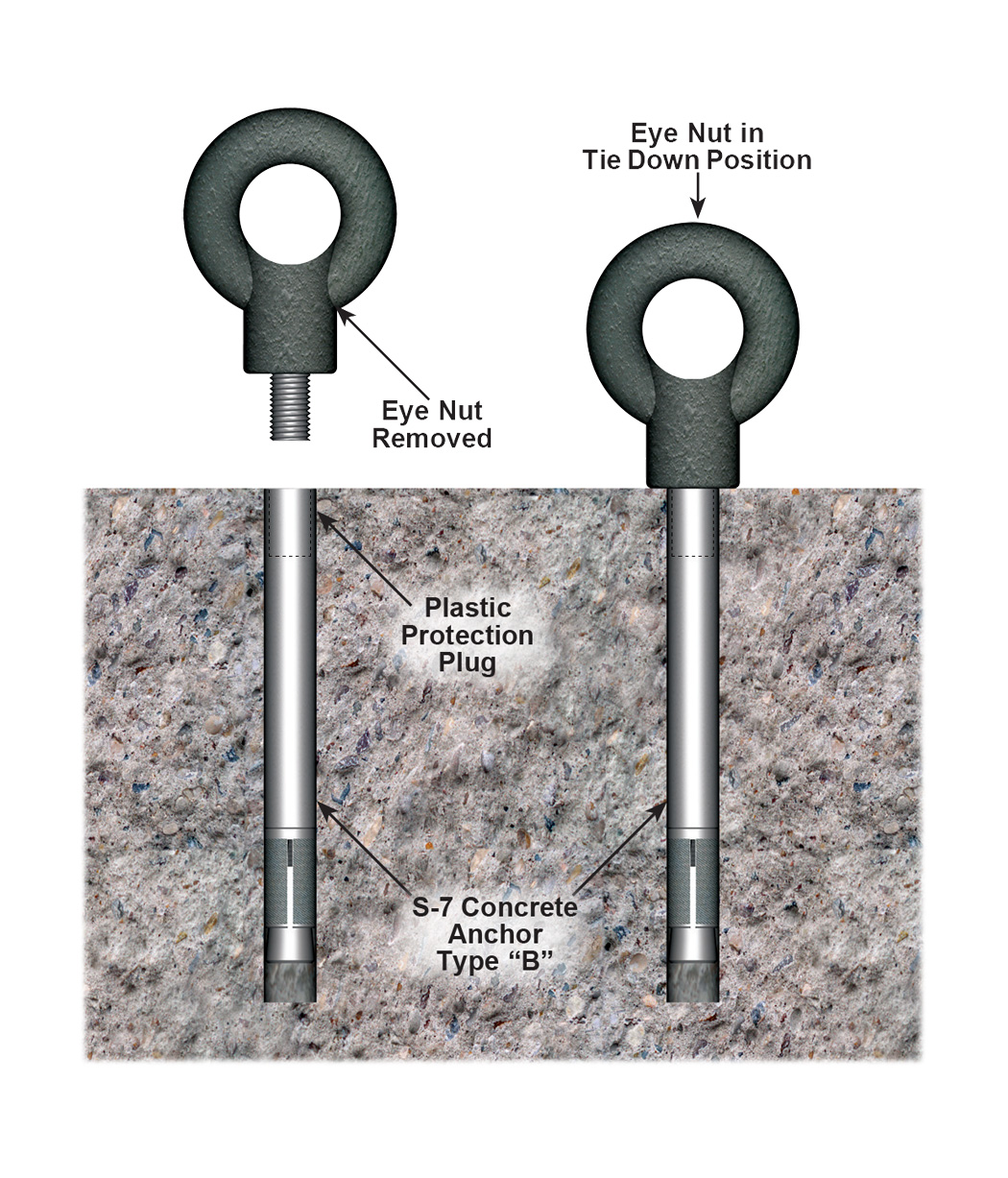

S-7 Reusable Concrete Anchor u2013 Williams Form Engineering Corp.

The 7 Most Common Types of Concrete Anchors Zoro.com

Concrete Screws for Projects – How to Fasten Anything to Concrete

Drilling Concrete and Installing Fasteners Family Handyman

How to Install Masonry u0026 Concrete Anchors Fasteners 101

How to Remove Concrete Anchors: The Complete Guide

Concrete Screws for Projects – How to Fasten Anything to Concrete

Related articles:

- How To Seal Concrete Floor In Garage

- Concrete Floor Thickness Industrial

- Acid Stain Basement Concrete Floor

- Concrete Floor Hole Repair

- How To Seal Concrete Floor Before Painting

- Concrete Floor Epoxy Filler

- Wood Flooring Over Concrete Floor

- Pex Concrete Floor Heating

- Acid Stain Concrete Floors Yourself

- Stained Concrete Floor Color Charts

Concrete Floor Fasteners: Secure Your Flooring with Confidence

Introduction:

When it comes to securing flooring installations, concrete floor fasteners play a crucial role. These small but mighty components provide the necessary strength and stability to ensure that your floors stay firmly in place. Whether you’re working on a residential project or a commercial construction venture, understanding the different types of concrete floor fasteners available and how to use them is essential. In this article, we will delve into the world of concrete floor fasteners, exploring their various types, applications, installation methods, and frequently asked questions.

I. Types of Concrete Floor Fasteners:

1. Concrete Screws:

Concrete screws are one of the most popular types of fasteners used for securing flooring to concrete surfaces. These screws feature a unique thread design that allows them to bite into the concrete, providing exceptional holding power. They are often made from hardened steel or stainless steel to withstand the harsh conditions of concrete environments.

FAQs:

Q: Can I use regular screws instead of concrete screws?

A: Regular screws are not suitable for use on concrete surfaces as they lack the necessary thread design and hardness to penetrate and hold in place effectively.

Q: Do I need any special tools to install concrete screws?

A: Yes, to install concrete screws, you will need a hammer drill with a masonry bit for creating pilot holes in the concrete surface.

2. Concrete Anchors:

Concrete anchors are another popular choice for securing flooring onto concrete slabs. These fasteners are typically inserted into pre-drilled holes in the concrete and then expanded or set using specialized tools. Depending on the specific type of anchor used, they can provide excellent holding strength and are available in various configurations such as wedge anchors, sleeve anchors, or drop-in anchors.

FAQs:

Q: How do I choose the right type of concrete anchor for my project?

A: The choice of anchor depends on factors such as load requirements, concrete thickness, and the type of flooring being installed. Consulting with a professional or referring to manufacturer guidelines can help you select the appropriate anchor for your project.

Q: Can I reuse concrete anchors?

A: Reusing concrete anchors is generally not recommended as their holding strength may diminish over time due to wear and tear or damage during removal. It is best to use new anchors for each installation.

3. Concrete Wedge Inserts:

Concrete wedge inserts, also known as threaded inserts, are specifically designed for attaching objects to concrete floors. These fasteners consist of two main components: the threaded insert itself and a corresponding bolt. The threaded insert is embedded into the concrete surface using epoxy adhesive or by drilling a hole and screwing it in. Once in place, the bolt is inserted into the threaded insert, allowing for easy attachment and removal of objects.

FAQs:

Q: Can I install concrete wedge inserts without using epoxy adhesive?

A: While epoxy adhesive provides additional strength and stability, it is possible to install concrete wedge inserts without it. However, the holding capacity may be reduced compared to using adhesive.

Q: Are there any weight limitations when using concrete wedge inserts?

A: The weight capacity of concrete wedge inserts depends on factors such as the size and depth of the insert, as well as the quality of the concrete. It is crucial to consult product specifications or seek professional advice to determine weight limitations.

II. Applications of Concrete Floor Fasteners:

1. Residential Flooring:

Concrete floor fasteners play a vital role in securing various types of flooring in residential settings. Whether You are installing tiles, hardwood, or laminate flooring on a concrete slab, using the right fasteners ensures a secure and long-lasting installation. Concrete screws, anchors, and wedge inserts can all be used for residential flooring applications.

2. Commercial Flooring:

In commercial buildings such as offices, retail stores, or warehouses, concrete floor fasteners are essential for securing heavy-duty flooring materials. These fasteners provide the necessary strength and stability to handle high foot traffic and heavy loads. Common applications include installing vinyl or carpet tiles, epoxy coatings, or industrial-grade flooring.

3. Outdoor Flooring:

Concrete floor fasteners are also used for outdoor flooring projects. Whether it’s a patio, driveway, or walkway, these fasteners ensure that the outdoor flooring material stays in place even under harsh weather conditions. In addition to anchoring the flooring material to the concrete surface, they also provide resistance against shifting or movement caused by natural elements.

4. Industrial Flooring:

Industrial facilities such as factories, warehouses, or manufacturing plants require durable and secure flooring solutions. Concrete floor fasteners are commonly used to install heavy-duty flooring materials such as epoxy coatings, polished concrete, or specialized industrial tiles. These fasteners can withstand the demands of heavy machinery, chemical spills, and high impact loads.

In conclusion, concrete floor fasteners are essential tools for securely attaching various types of flooring to concrete surfaces. Depending on the specific application and requirements of your project, you may choose to use concrete screws, anchors, or wedge inserts. It is important to select the appropriate type of fastener and follow proper installation techniques to ensure a reliable and long-lasting result. Concrete floor fasteners are crucial for securing different types of flooring in various settings, including residential, commercial, outdoor, and industrial applications. They provide strength, stability, and durability to ensure a secure and long-lasting installation.

In residential flooring, concrete floor fasteners are used to secure tiles, hardwood, or laminate flooring on a concrete slab. The right fasteners ensure that the flooring material stays in place and can withstand regular use.

For commercial buildings like offices, retail stores, or warehouses, concrete floor fasteners are essential for securing heavy-duty flooring materials. These fasteners can handle high foot traffic and heavy loads, making them suitable for applications such as vinyl or carpet tiles, epoxy coatings, or industrial-grade flooring.

Concrete floor fasteners are also used for outdoor flooring projects such as patios, driveways, or walkways. They ensure that the outdoor flooring material remains stable even under harsh weather conditions and provide resistance against shifting or movement caused by natural elements.

In industrial facilities like factories, warehouses, or manufacturing plants, durable and secure flooring solutions are necessary. Concrete floor fasteners are commonly used to install heavy-duty flooring materials such as epoxy coatings, polished concrete, or specialized industrial tiles. These fasteners can withstand the demands of heavy machinery, chemical spills, and high impact loads.

In conclusion, concrete floor fasteners are essential tools for securely attaching various types of flooring to concrete surfaces. It is important to select the appropriate type of fastener and follow proper installation techniques to ensure a reliable and long-lasting result.