A polished concrete floor does not have to have regular cleaning, meaning that you are able to cleanse them alternatively or whenever you are absolutely free. Concrete is extremely long lasting and hardly ever has to be replaced though you could have to touch up the finish that is a pretty easy and inexpensive job. With all these advantages, one of the main benefits of concrete floors is its pricing.

Here are Images about Concrete Floor Epoxy Crack Filler

Concrete Floor Epoxy Crack Filler

On top of this, one of the best characteristics of concrete flooring is its trouble free cleaning characteristic in which the particles of dust can be easily mopped. While many do not think about a concrete floor in the home of theirs for the worry of it being very cold, the opposite is actually correct. For daily regime, a soft broom or even dust mop is effective.

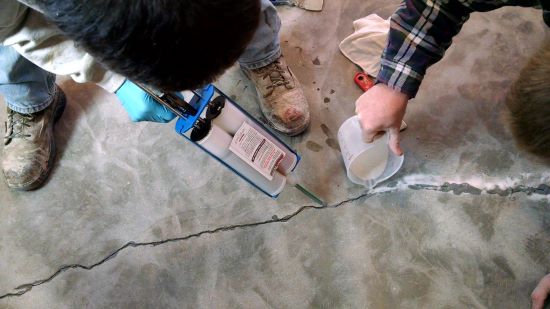

DIY Epoxy Concrete Crack Repair – What I use – How I Repair Concrete

Developing with concrete countertops out of doors is also attractive because of their easy maintenance and huge design flexibility. Concrete polishing is actually the finish of choice for most owners of new and present concrete floors. Polished concrete is actually seamless, leaving no place for dust mites to assemble and expose the bacteria which could be caught between floorboards and tiles.

Images Related to Concrete Floor Epoxy Crack Filler

Epoxy Concrete Repair Crack Treatment and Concrete Crack Filler

How to Repair Garage Floor Cracks and Pitting All Garage Floors

High strength anchored epoxy paste epoxy repair concrete cracks

Concrete crack repair and filler 100% Solid Epoxy Filler

E443 Quick Fix Concrete Repair Epoxy Urethane Cartridge Kit Low Temp 0°F

Foundation Crack Repair in 8 Steps – This Old House

/cdn.vox-cdn.com/uploads/chorus_asset/file/19495119/00_concrete_xl.jpg)

When to call a professional to repair cracked concrete

Foundation Floor Crack Repair CrackX

How To Apply Concrete Floor Crack Filler Before Epoxy? – Ultimate

Repairing Common Concrete Slab Problems – Concrete Network

Introducing Sika Injectokit TH Concrete Crack Repair System

How to Repair Cracks in Concrete Floors

/GettyImages-147217539-584b09cb3df78c491e1ab228.jpg)

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Epoxy crack filler is an effective and efficient way to repair cracks in concrete floors. It is a strong, durable, and flexible material that can be used to repair a wide variety of cracks in both residential and commercial concrete floor surfaces. This type of repair is typically less expensive than replacing the entire floor and can be done quickly, making it an ideal solution for those looking to restore their floor’s appearance. In this article, we’ll discuss the various types of epoxy crack fillers, the benefits of using them, and how to select the right one for your project.

Types of Epoxy Crack Fillers

When it comes to epoxy crack fillers, there are two main types: self-leveling and non-self-leveling. Self-leveling epoxy crack fillers are designed to spread out evenly across the surface of the crack and form a smooth, seamless seal. Non-self-leveling epoxy crack fillers are thicker in consistency and require a bit more work to apply. They form a stronger bond with the concrete and are better at filling deep cracks or those with large surface areas.

Benefits of Using Epoxy Crack Fillers

Epoxy crack fillers offer numerous benefits when compared to other materials. They are strong, durable, and easy to apply. They form a tight bond with the concrete surface that prevents water from seeping in, which helps keep your concrete floor intact for longer. Epoxy crack fillers also provide an aesthetically pleasing finish that can help improve the overall look of your space. Additionally, they are available in a variety of colors so you can match the color of your existing floor or create a new design element.

How to Select an Epoxy Crack Filler

When choosing an epoxy crack filler for your project, there are several factors you should consider. First, determine which type of epoxy is best suited for your particular situation: self-leveling or non-self-leveling. Next, decide on the color you’d like to use. You can either choose one that matches your existing floor color or find one that complements the design elements in your space. Finally, consider whether you’d like a glossy or matte finish.

FAQs

Q: How long does it take for an epoxy crack filler to dry?

A: It depends on the type of product you’re using and the temperature and humidity levels in your area. Generally speaking, most epoxy crack fillers will take at least 24 hours to completely dry.

Q: How do I apply an epoxy crack filler?

A: First, make sure the area is clean and free from debris. Then, follow the instructions on the product packaging to mix the two parts of the epoxy together. Once mixed, apply it to the cracked area with either a brush or roller (depending on the type of product you’re using). Allow it to dry for at least 24 hours before walking on it or applying any additional coatings.

Q: Is epoxy crack filler waterproof?

A: Yes, epoxy crack filler forms a strong bond with concrete surfaces that prevents water from seeping through, making it highly resistant to moisture damage.

Conclusion

Epoxy crack filler is an effective and efficient way to repair cracks in concrete floors while providing numerous benefits such as strength, durability, and waterproofing properties. When selecting an epoxy crack filler for your project, be sure to consider which type is best suited for your particular situation as well as factors such as color and finish type.