price which is Low, durability and little maintenance make this the perfect flooring option for manufacturing, business as well as other high traffic scenarios. With this specific technology of concrete floors, the floor is kept hot even in the coldest climate and also you can hike on the floor even without the need for footwear.

Here are Images about Concrete Floor Construction With Insulation

Concrete Floor Construction With Insulation

Each time you will undertake maintenance job for the polished concrete floors of yours, you require spending simply a portion of capital as in comparison to other flooring available options. In domestic ways polished concrete floors are actually chosen for its good looks, but in manufacturing situations it's preferred due to practicality; these floor surfaces are also really functional.

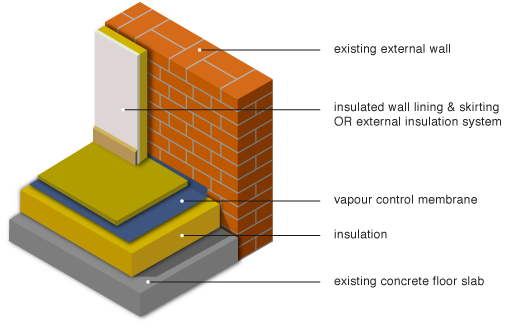

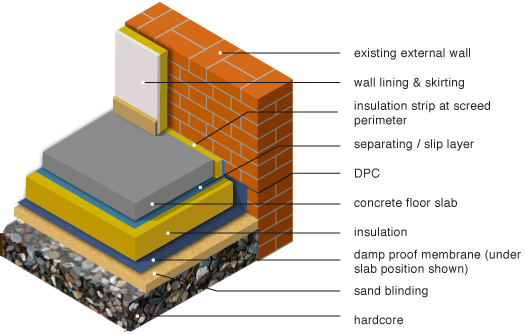

GreenSpec: Housing Retrofit: Ground Floor Insulation

In order to change the color of the floor, buyers may request shake-on color hardeners or penetrating synthetic stains and dyes to modify their grey concrete to any kind of number of styles. In recent times which has transformed as more and more people are realizing that a polished concrete floor really looks great. Polished concrete flooring looks much more slippery than it's.

Images Related to Concrete Floor Construction With Insulation

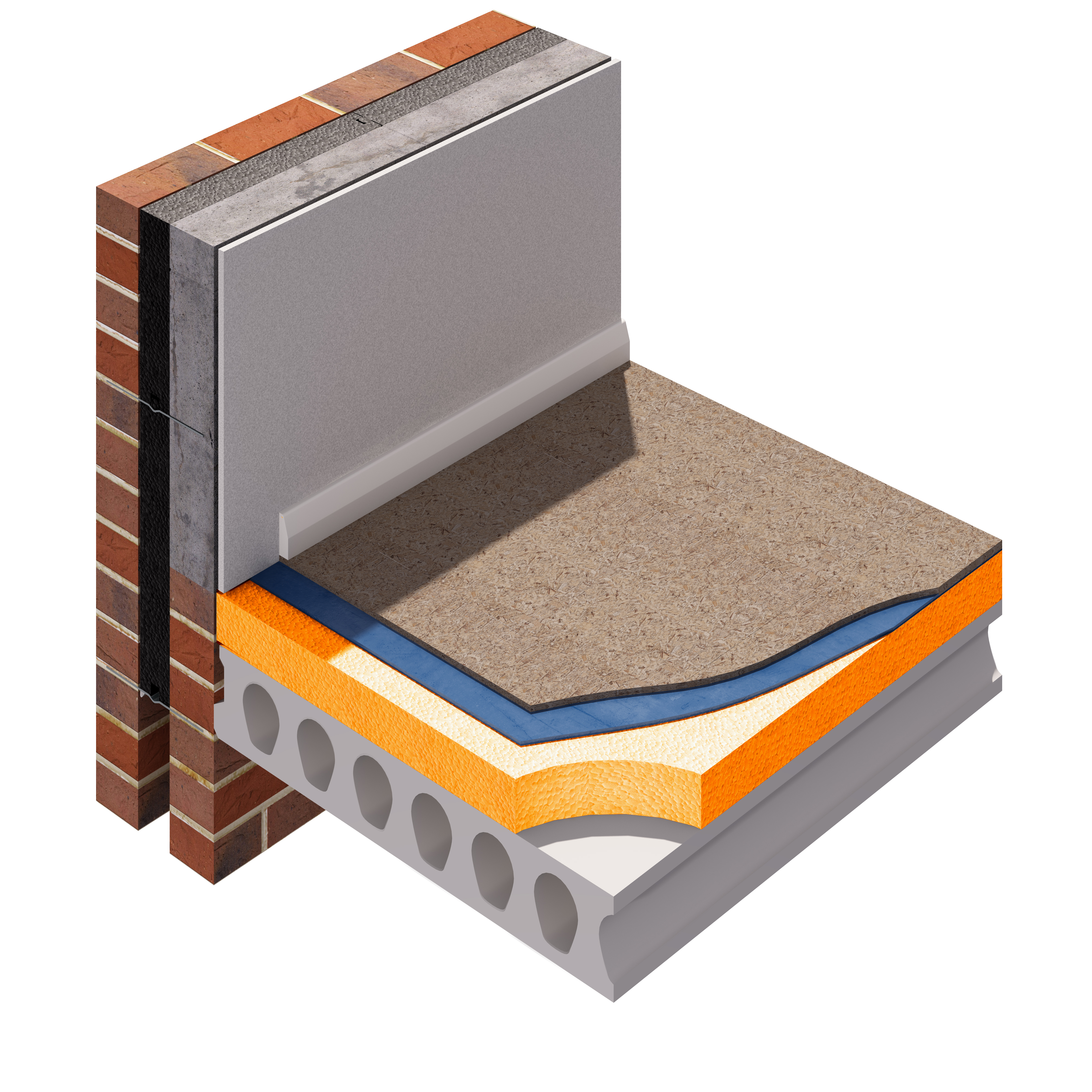

Insulating Over a Structural Slab JLC Online

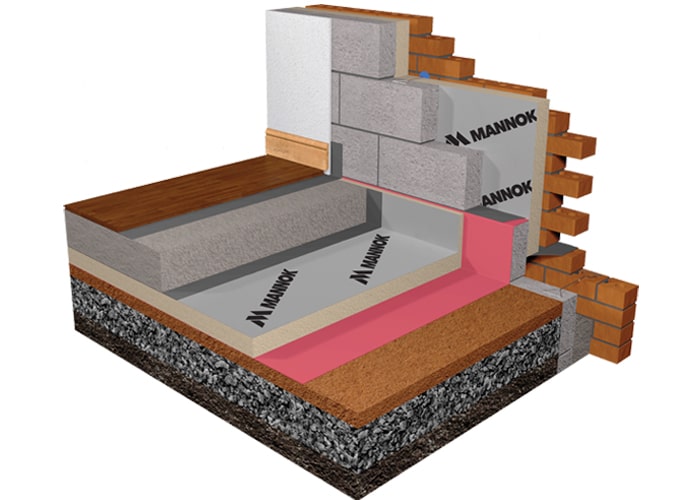

Ground floor – insulation below concrete slab – Polyfoam XPS

Floor insulation – Optimal Insulation

Floor Construction Methods Concrete floors, Concrete furniture

Thermal Insulation for Concrete Slab Floors

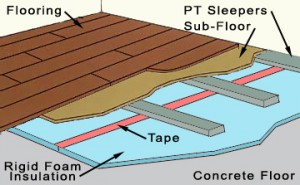

Basement Flooring – How To Insulate A Concrete Floor

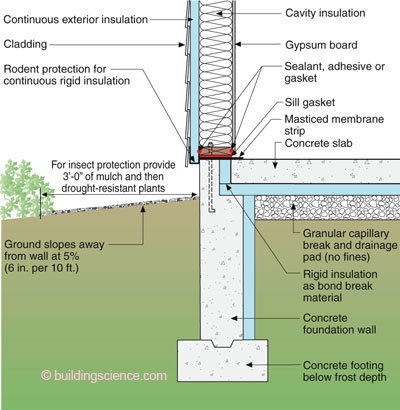

Slab Happy u2013 Concrete Engineering Building Science

GreenSpec: Housing Retrofit: Ground Floor Insulation

Insulation for ground floors – Designing Buildings

Insulation Retrofit for an Existing Concrete Slab and 2×4 Walls

Insulated Concrete Flooring Thermabeam™ GB FP McCann

How to Insulate a Concrete Floor Kingspan MEA u0026 India

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Installing insulation in concrete floors is a great way to reduce energy costs and ensure the integrity of the flooring in the long run. This type of construction is relatively simple, but it does require careful planning and execution in order to get the best results. In this article, we’ll take a look at how to install insulation in concrete floors and why it’s beneficial.

What Makes Insulated Concrete Floors Beneficial?

Concrete floors are incredibly durable and require minimal maintenance, but they can also be difficult to cool or heat as needed. By adding insulation, you can make sure that your concrete floor retains whatever temperature you set and keep it regulated across all seasons. This helps you save a significant amount of energy and money while also allowing you to enjoy a comfortable living space.

In addition, insulation helps protect your concrete floor from any moisture damage or mold growth that could occur due to water seeping in through the cracks. It also adds an extra layer of protection against any noise or vibration that may come from outside sources.

How To Install Insulation In Concrete Floors?

The first step to installing insulation in a concrete floor is to assess the condition of the floor itself. Make sure there are no cracks or uneven surfaces that could cause problems later on. Once you’ve done that, you can start laying down the insulation. There are several different types of insulation available, including foam boards, rigid foam boards, and spray-in foam insulation.

Foam boards are easy to install and offer good thermal resistance, but they don’t provide as much soundproofing as other options. Rigid foam boards are more difficult to install but provide better soundproofing as well as thermal protection. Spray-in foam insulation is the most expensive option but offers the most protection against both temperature and sound.

Once you’ve chosen the type of insulation you want to use, you’ll need to cut it into the right size for your concrete floor and lay it down carefully over the entire surface. Make sure it’s flush with the edges of the floor and fill in any gaps with caulk or expanding foam before sealing it with a vapor barrier. Finally, put down a layer of plywood or other material over the top before laying down your choice of flooring.

FAQs:

Q: Can I install insulation in a concrete floor myself?

A: Yes, installing insulation in a concrete floor is relatively simple and can be done by anyone with basic DIY skills. However, if you’re not confident in your abilities, it may be best to hire a professional for the job.

Q: How much insulation do I need for my concrete floor?

A: The amount of insulation you need will depend on how well insulated your building is and what type of insulation you choose to use. Generally speaking, R-values between 3 and 6 are recommended for most residential applications.

Q: How often should I replace my insulation?

A: The lifespan of your insulation will depend on its quality and how well it has been maintained over time. Generally speaking, foam board or rigid foam board insulation should last between 10-15 years while spray-in foam insulation can last up to 25 years or more.

Conclusion

Installing insulation in concrete floors is an effective way to improve energy efficiency while also protecting against noise and moisture damage. It’s relatively simple to do yourself if you have basic DIY skills, but if not it may be best to hire a professional for the job. With proper installation and maintenance, your insulated concrete floor should last for many years without any issues.