The latest innovations in the capability to seal as well as stain concrete have raised the aesthetic appeal of its, allowing it to play with other stone flooring such as marble, granite and slate – at a tiny proportion of the price. Be an intelligent person and embrace concrete as flooring surfaces that's not just safe for you but also to the planet.

Here are Images about Concrete Floor And Slab Construction

Concrete Floor And Slab Construction

Hiring specialized concreters or even concrete contractors might cost you a bit however, you're sure of a much better result. Concrete floors are greatly recommended from the American Lung Association for people with allergies and asthma. Every one of the above sorts of polished concrete floors may be completed in huge looks and styles.

Concrete Floor Slab Construction Process – The Constructor

Wooden floors call for varnishing on a routine schedule, carpets can be a nightmare which need to be cleaned regularly, while the concrete floor surfaces are actually lasting and don't require some maintenance, apart from a cleaning as needed. Now cleaning on a polished concrete floors is much easier and demands less time. Concrete floors may be polished dry or wet.

Images Related to Concrete Floor And Slab Construction

Concrete slab floor construction BRANZ Renovate

Mum u0026 Dad Shed – Concrete slab floor construction BRANZ Renovate

STRUCTURE magazine Creating an Opening in Existing Floors

What Is Floating Slab Floating Slab Construction How to Build a

Slab On Grade Foundation Design Slab On Grade Design

What Is Floating Slab Floating Slab Construction How to Build a

11-Construction detail of the concrete slab-on-ground floored case

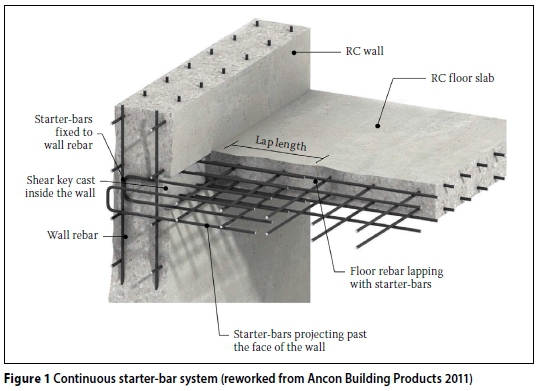

Alternative wall-to-slab connection systems in reinforced concrete

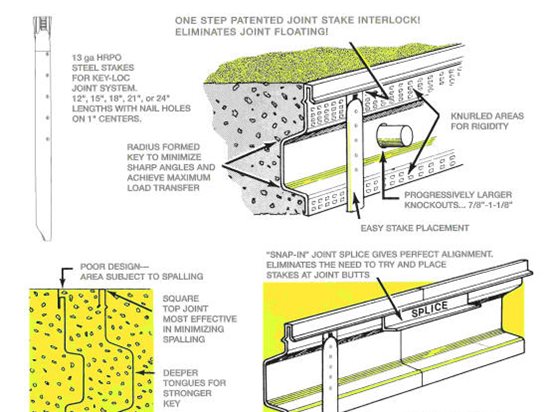

Construction Joints in Concrete Slabs – Concrete Network

Concrete slab – Wikipedia

Concrete Floor Slab Construction Process. Bottom-up method.

Concrete slab floors YourHome

Related articles:

- Concrete Flooring Pretoria

- Concrete Floor Coverings For Patios

- Concrete Floor Stain Pictures

- Behr Concrete Floor Sealer

- Stained Concrete Floor Tiles

- Gray Concrete Floor Paint

- How To Paint Old Concrete Floor

- Stained Concrete Floor Finishes

- Concrete Floor Cost Estimator

- Stained Concrete Floors How To

Concrete floor and slab construction is a crucial aspect of building design and construction. Whether it’s for residential, commercial, or industrial purposes, concrete floors and slabs provide a durable and long-lasting foundation for buildings. In this article, we will discuss the various aspects of concrete floor and slab construction, including materials, methods, and common FAQs.

Materials Used in Concrete Floor and Slab Construction

One of the key components of concrete floor and slab construction is the materials used. The primary material used in concrete construction is cement, which is mixed with water, sand, and aggregate to create a strong and durable concrete mixture. Reinforcing materials such as rebar or wire mesh are often added to increase the strength and stability of the concrete.

FAQs:

Q: What type of cement is best for concrete floor construction?

A: Portland cement is the most commonly used type of cement in concrete construction due to its durability and strength.

Q: Do I need to add reinforcement to my concrete floor?

A: It is recommended to add reinforcement such as rebar or wire mesh to improve the strength of your concrete floor, especially for high-traffic areas.

Methods of Concrete Floor and Slab Construction

There are several methods used in concrete floor and slab construction, depending on the specific requirements of the project. One common method is traditional cast-in-place construction, where wet concrete is poured into forms on-site and allowed to cure. Another method is precast concrete construction, where concrete elements are cast off-site and transported to the construction site for installation.

FAQs:

Q: What is the difference between cast-in-place and precast concrete construction?

A: Cast-in-place construction involves pouring wet concrete on-site, while precast construction involves casting concrete elements off-site before installation.

Q: Which method is more cost-effective for concrete floor construction?

A: The cost-effectiveness of cast-in-place versus precast construction depends on various factors such as project size, complexity, and timeline.

Design Considerations for Concrete Floor and Slab Construction

When designing a concrete floor or slab, several factors need to be considered to ensure a successful construction process. These factors include load-bearing capacity, moisture resistance, surface finish requirements, and thermal properties. Proper planning and design are essential to ensure that the finished product meets all necessary specifications.

FAQs:

Q: How can I ensure that my concrete floor can support heavy loads?

A: It is important to consult with a structural engineer to determine the appropriate thickness and reinforcement needed for your specific load requirements.

Q: What surface finishes are available for concrete floors?

A: Concrete floors can be finished in various ways, including polished, stained, stamped, or sealed finishes depending on aesthetic preferences and functional requirements.

Common Issues in Concrete Floor and Slab Construction

Despite its durability, concrete floors and slabs can experience issues over time due to various factors such as inadequate curing, improper installation techniques, or environmental conditions. Common issues include cracking, spalling (surface deterioration), curling (upward bending at edges), or delamination (layer separation).

FAQs:

Q: How can I prevent cracking in my concrete floor?

A: Proper curing techniques such as using curing compounds or coverings can help prevent cracking in newly poured concrete floors.

Q: What causes spalling in concrete floors?

A: Spalling can occur due to freeze-thaw cycles, chemical exposure, or poor surface preparation during installation.

Maintenance Tips for Concrete Floors

To ensure the longevity and performance of your concrete floors , regular maintenance is essential. Some maintenance tips for concrete floors include:

1. Regular cleaning: Sweep or vacuum the floor regularly to remove dirt and debris that can scratch the surface.

2. Sealing: Apply a high-quality sealer to protect the surface from stains, water damage, and wear-and-tear.

3. Repair cracks promptly: Fill in any cracks or holes in the concrete to prevent them from getting larger and causing further damage.

4. Avoid harsh chemicals: Use gentle cleaning solutions to avoid damaging the surface of the concrete.

5. Protect with rugs or mats: Place rugs or mats in high-traffic areas to prevent wear and tear on the surface of the concrete.

By following these maintenance tips, you can keep your concrete floors looking great and performing well for years to come.

FAQs:

Q: How often should I seal my concrete floor?

A: It is recommended to reseal your concrete floor every 1-3 years, depending on the amount of traffic and wear it receives.

Q: Can I repair cracks in my concrete floor myself?

A: Small cracks can be repaired using a concrete patching compound available at most hardware stores. However, larger cracks may require professional repair to ensure a proper fix.

By following these maintenance tips and addressing any issues promptly, you can ensure that your concrete floors remain in top condition and continue to provide durability and functionality for years to come.

Remember, proper maintenance is key to preserving the longevity and performance of your concrete floors. By addressing issues promptly and following these maintenance tips, you can enjoy beautiful, durable, and functional concrete floors for years to come. If you have any further questions or concerns about your concrete floors, don’t hesitate to consult with a professional for guidance and assistance.