Polished concrete flooring is a great approach to save resources. Concrete flooring takes some time to loosen up, but is very economical at holding that heat in, which means the home of yours will continue to be warm on winter nights. Maintaining the concrete floor coating of yours is simple. Polished concrete floors are very easy to keep and manage.

Here are Images about Cast In Place Concrete Flooring Systems

Cast In Place Concrete Flooring Systems

In certain cases, all that will be needed is an easy rebuffing of the flooring with a bit of polishing compound. Remember it's vital to use concrete floor sealers that will help safeguard the surface area. It's true a visitor requires quite some basic strategy of looking after these concrete floors but certain facts about maintenance that have to be saved in mind.

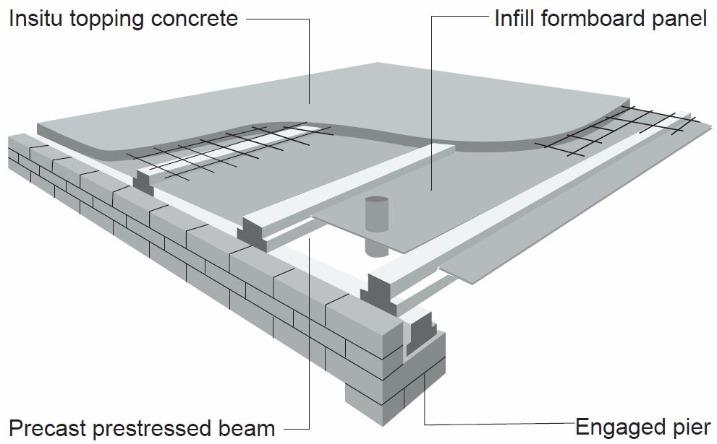

Precast Concrete Floor Systems Types Of Precast Concrete Floors

Polished concrete floors can be the first step on to building an allergy free environment. Polished concrete is becoming a favorite office floor option due to its longevity, easy upkeep, and sizable selection of colors and decorative choices. You can likewise mop it using warm, soapy drinking water, but only using a mild detergent.

Images Related to Cast In Place Concrete Flooring Systems

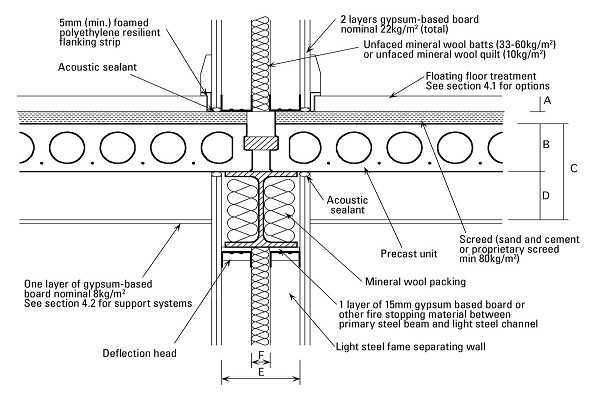

Situ Concrete – an overview ScienceDirect Topics

Insulated Concrete Floors u2022 Insul-Deck Insulated Concrete Forms

Cast in Place Concrete – an overview ScienceDirect Topics

Steel Decking for Concrete Floors, Ecospan, Get More for Less

Removable Forms (Cast-In Place)

Cast-In-Place Concrete – Buildipedia

Examples of the scenarios proposed: (a) Concrete Floor System

Commonly used arrangements of Precast Members and Cast in Place

Commercial Floor Systems – ppt download

Upper Floors

STRUCTURE magazine Creating an Opening in Existing Floors

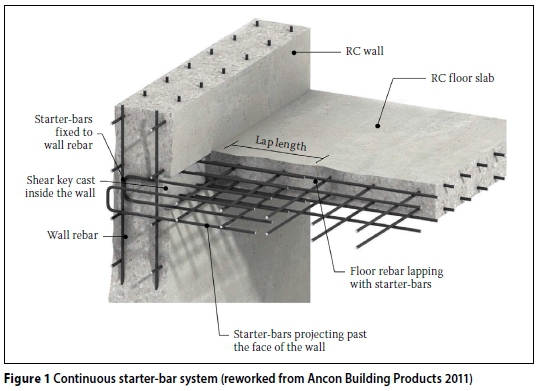

Alternative wall-to-slab connection systems in reinforced concrete

Related articles:

- Leveling Old Concrete Floor

- Smooth Concrete Floor Finish

- Concrete Floor Heating Installation

- Polished Concrete Floor Over Wood Subfloor

- How To Pour A Concrete Floor Over A Basement

- Concrete Floor Cleaning Machines For Rent

- Best Epoxy Concrete Floor Paint

- Concrete Floor Interior House

- Concrete Flooring Pretoria

- Concrete Floor Coverings For Patios

Cast In Place Concrete Flooring Systems: A Comprehensive Guide

Introduction

Cast-in-place concrete flooring systems, also known as poured-in-place or monolithic concrete floors, are a popular choice for both residential and commercial projects. This versatile flooring solution offers durability, strength, and a seamless finish that can enhance the aesthetics of any space. In this article, we will explore the various aspects of cast-in-place concrete flooring systems, including their advantages, installation process, maintenance requirements, and frequently asked questions.

Advantages of Cast In Place Concrete Flooring Systems

1. Strength and Durability

Cast-in-place concrete flooring systems are renowned for their exceptional strength and durability. The monolithic nature of the installation eliminates joints and seams that are prone to cracking or weakening over time. With proper maintenance, these floors can withstand heavy loads, foot traffic, and even vehicular movement without compromising their structural integrity.

2. Versatility in Design

One of the key advantages of cast-in-place concrete flooring systems is their versatility in design. They can be customized to suit various aesthetic preferences, ranging from polished finishes to decorative patterns or textures. Additionally, integrally colored pigments can be added to the concrete mix to achieve a wide array of hues and shades, allowing for endless design possibilities.

3. Cost-Effectiveness

Cast-in-place concrete flooring systems offer excellent long-term value for money. While the initial installation cost may be higher compared to some other flooring options, the durability and low maintenance requirements significantly reduce lifetime costs. Moreover, these floors can serve as a base for various floor coverings such as tiles or carpeting if desired in the future.

Installation Process of Cast In Place Concrete Flooring Systems

1. Site Preparation

Before pouring the concrete, proper site preparation is crucial to ensure a successful installation. The area should be cleared of any debris or vegetation, and the subgrade should be compacted to provide a stable base for the concrete. Additionally, any necessary forms or edge restraints should be installed to define the boundaries of the concrete slab.

2. Reinforcement Placement

Reinforcement is essential to enhance the strength and structural integrity of the cast-in-place concrete flooring system. Steel reinforcement, such as rebar or wire mesh, is typically placed within the concrete slab to distribute loads and prevent cracking. The type and amount of reinforcement required will depend on factors such as the anticipated loadings and the thickness of the slab.

3. Concrete Pouring

Once the site is prepared and reinforcement is in place, the concrete can be poured. A carefully selected and properly proportioned concrete mix is poured into the defined area and spread evenly using screeds and bull floats to achieve a level surface. During this process, it is crucial to avoid overworking the concrete, as it can lead to a weakened finish.

4. Curing and Finishing

After pouring, the cast-in-place concrete flooring system needs adequate time to cure. Curing involves maintaining proper moisture levels in the concrete for an extended period to promote optimal strength development. Once cured, various finishing techniques can be applied to achieve desired aesthetics, such as polishing, staining, or applying decorative patterns.

Maintenance Requirements of Cast In Place Concrete Flooring Systems

1. Regular Cleaning

To maintain the appearance and longevity of cast-in-place concrete flooring systems, regular cleaning is essential. Sweeping or vacuuming should be done regularly to remove dirt and debris that can cause abrasion or scratches on the surface. Additionally, mopping with a mild detergent solution can help remove stains And keep the floor looking clean and fresh. It is important to avoid using harsh chemicals or abrasive cleaners, as they can damage the finish of the concrete.

2. Sealing and Resealing

To protect the surface of the cast-in-place concrete flooring system, it is recommended to apply a sealer. This will help prevent staining and make cleaning easier. The frequency of resealing will depend on factors such as foot traffic and exposure to moisture or chemicals. It is important to follow the manufacturer’s instructions for the specific sealer being used.

3. Preventive Maintenance

Taking preventive measures can help prolong the lifespan of cast-in-place concrete flooring systems. This includes using furniture pads or coasters to prevent scratches or dents, avoiding dragging heavy objects across the floor, and promptly addressing any spills or stains to prevent them from penetrating into the concrete.

4. Regular Inspections

Regular inspections of the cast-in-place concrete flooring system can help identify any potential issues early on. This includes checking for cracks, unevenness, or signs of wear and tear. Any necessary repairs should be addressed promptly to prevent further damage.

By following these maintenance requirements, cast-in-place concrete flooring systems can continue to provide a durable and aesthetically pleasing flooring option for many years to come. Regular cleaning is important to maintain the appearance and longevity of cast-in-place concrete flooring systems. Sweeping or vacuuming should be done regularly to remove dirt and debris that can cause abrasion or scratches. Mopping with a mild detergent solution can help remove stains and keep the floor looking clean. Harsh chemicals or abrasive cleaners should be avoided as they can damage the finish of the concrete.

Applying a sealer is recommended to protect the surface of the cast-in-place concrete flooring system. This will help prevent staining and make cleaning easier. The frequency of resealing will depend on factors such as foot traffic and exposure to moisture or chemicals. It is important to follow the manufacturer’s instructions for the specific sealer being used.

Taking preventive measures can help prolong the lifespan of cast-in-place concrete flooring systems. This includes using furniture pads or coasters to prevent scratches or dents, avoiding dragging heavy objects across the floor, and promptly addressing any spills or stains to prevent them from penetrating into the concrete.

Regular inspections of the cast-in-place concrete flooring system are also important. This includes checking for cracks, unevenness, or signs of wear and tear. Any necessary repairs should be addressed promptly to prevent further damage.

By following these maintenance requirements, cast-in-place concrete flooring systems can continue to provide a durable and aesthetically pleasing flooring option for many years to come. Overall, the maintenance requirements for cast-in-place concrete flooring systems include regular cleaning, applying a sealer, taking preventive measures, and conducting regular inspections. By following these maintenance practices, the lifespan of cast-in-place concrete flooring systems can be prolonged, ensuring their durability and aesthetic appeal for many years.