But on the upside of items, and also for a big change, concrete floor might actually look quite good if it’s finished properly. Polished concrete floors unlike other floors provide significantly less maintenance and the reflective nature of its maximizes organic light saving you substantial amount of power. Concrete floors might be painted, stained, glossed or perhaps improved with various other substances as preferred by the homeowner.

Here are Images about Building A Concrete Floor

Building A Concrete Floor

Diamond concrete floors polishing offers consumers a number of options to change the look of the floors of theirs. Beyond sweeping and scrubbing the floor, create a detailed concrete floor care method which includes stripping the floor if needed and sealing and buffing. The compounds used to seal concrete floors have absolutely no lasting odour.

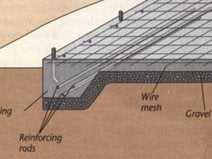

How Thick Should a Concrete Slab be? – The Constructor

Remember concrete flooring can be covered with several materials like epoxy, a beautiful durable finish which can be used somewhere in the house. Concrete office flooring is a light green option which frequently outlasts other floor kinds as linoleum, wood, tile, and carpet.

Images Related to Building A Concrete Floor

Concrete Floor Slab Construction Process – The Constructor

How to Pour a Concrete Slab for Beginners DIY

Garage Build Part 13 – Preparing the floor to pour concrete

Concrete slab floor and how to make one by hand mixing the concrete

How to Pour a Concrete Slab (DIY) Family Handyman

How to Place and Finish a Concrete Floor (with Pictures) – wikiHow

Concrete Floor Slab Construction Process. Bottom-up method.

What Is Floating Slab Floating Slab Construction How to Build a

Concrete Flatwork Tips for Your Morton Building Project

Concrete Slab Types – Construction, Cost, and Applications – The

3 Types of Concrete Foundations – Slab on Grade, T-Shaped, Frost

Types of Economical Floor Systems for Reinforced Concrete Buildings

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Building a Concrete Floor: A Comprehensive Guide

A concrete floor is an excellent choice for any home or commercial building. It is durable, low maintenance, and provides a safe and attractive surface. With the right tools and materials, you can create a beautiful and long-lasting concrete floor in your own home.

In this guide, we will walk you through all the steps required to build a concrete floor. We’ll also provide answers to some of the most common questions about this process. Read on to learn more.

Tools and Materials Needed

Before beginning your concrete floor project, it’s important to make sure you have all the necessary tools and materials. Here is a list of what you’ll need:

– Hammer

– Nails

– Trowel

– Level

– Shovel

– Measuring Tape

– Concrete Mix

– Water

– Plywood or Masonite

– Caulk

– Polyethylene Sheeting

– Paint or Sealer (optional)

Preparing the Subfloor

The first step in building a concrete floor is to prepare the subfloor. This means removing any existing flooring material and making sure the surface is even and clean. If there are any cracks or large holes, they should be filled with a patching compound before proceeding. Once the subfloor is ready, you can begin laying down the plywood or masonite sheets that will form the base of the concrete floor. These should be secured with nails and caulked to ensure a tight seal.

Mixing the Concrete

Once the subfloor is prepared, it’s time to mix the concrete. This can be done by combining one part cement, two parts sand, and three parts gravel in a bucket or wheelbarrow. Then slowly add water until the mixture reaches a thick, creamy consistency. You can use a trowel or shovel to mix it thoroughly.

Pouring the Concrete

Once the concrete is mixed, it’s time to pour it into the area you’ve prepared. Start at one corner of the room and slowly pour out the concrete while using a trowel to spread it evenly across the surface. Make sure to leave enough space between each layer so that it can dry properly.

Finishing Touches

After pouring out all of the concrete, you can begin applying any finishing touches that you wish. You can paint or seal your floor for added protection, or add texture for aesthetic purposes. Polyethylene sheeting should also be laid over the top of your newly poured concrete floor to protect it from moisture damage while it cures.

Common Questions About Building A Concrete Floor

Q: How long does it take for a concrete floor to cure?

A: Generally speaking, a concrete floor takes around 28 days to fully cure and reach peak strength. It’s important to keep foot traffic off of your new floor until it has fully cured in order to keep it in good condition for years to come.

Q: What type of sealer should I use on my concrete floor?

A: The best type of sealer for a concrete floor depends on what type of finish you want and how much wear and tear your floor will experience over time. Generally speaking, an epoxy sealer is a great choice for both indoor and outdoor floors as it provides excellent protection against moisture damage.

Q: How do I prevent cracking in my concrete floor?

A: The best way to prevent cracking in your concrete floor is by making sure that it is poured correctly in multiple thin layers with plenty of space between each layer so that it can dry properly. Additionally, if you choose to use a sealer on your floor make sure that it is designed specifically for use with concrete floors as this will help reduce the risk of cracking due to temperature changes or heavy traffic over time.

Conclusion

Building a concrete floor may seem like an intimidating task, but with the right tools and materials it can be