Sealing a concrete basement floor is an essential step in protecting your home from moisture, mold, and damage. We will walk you through the benefits of sealing a concrete basement floor, the types of sealers available, the step-by-step process for sealing, maintenance tips, and common mistakes to avoid. At the end, we’ll address frequently asked questions to ensure you have all the information needed for a successful project.

Benefits of Sealing a Concrete Basement Floor

Moisture Protection

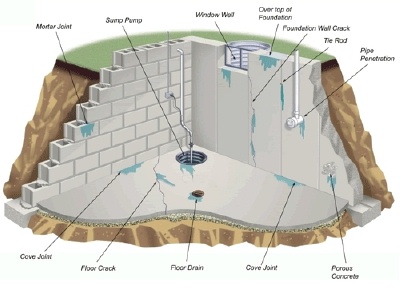

Sealing a concrete basement floor provides an effective barrier against moisture infiltration. Basements are prone to dampness due to their location below ground level, where they are in direct contact with soil and groundwater. A high-quality sealer prevents water vapor from seeping through the concrete, reducing the risk of dampness, mold growth, and mildew. This moisture protection is crucial for maintaining a dry and healthy basement environment, especially in regions with high humidity or heavy rainfall.

Enhanced Durability

Sealing a concrete basement floor significantly enhances its durability. Concrete, while strong, is porous and can absorb moisture and chemicals, leading to cracks, spalling, and deterioration over time. A sealer provides a protective layer that shields the concrete from wear and tear, extending its lifespan. This increased durability is particularly important for basements used as living spaces, storage areas, or workshops, where the floor is subjected to constant foot traffic and heavy loads.

Improved Aesthetic Appeal

A sealed concrete floor has a more attractive and finished appearance compared to unsealed concrete. Sealers can enhance the natural color of the concrete, give it a glossy or satin finish, and make it easier to clean. This improved aesthetic appeal can make the basement feel more inviting and comfortable, especially if you plan to use the space for living or recreational purposes. Additionally, decorative sealers can add a touch of style with various color options and finishes.

Easier Maintenance

Sealing a concrete basement floor makes it easier to maintain. The sealer creates a smooth, non-porous surface that resists staining and is easy to clean. Dust, dirt, and spills can be quickly wiped away without penetrating the concrete. Regular cleaning with a mild detergent and water is usually sufficient to keep a sealed floor looking its best. This ease of maintenance is a significant advantage for busy homeowners looking to minimize the time and effort spent on cleaning.

Increased Property Value

A well-maintained and sealed concrete basement floor can increase the overall value of your property. Potential buyers view a sealed basement floor as a sign of proper home maintenance and care, which can make your home more attractive on the market. Additionally, the added benefits of moisture protection, durability, and aesthetic appeal contribute to the overall value of the home. Investing in sealing your basement floor is a cost-effective way to enhance your property’s marketability and longevity.

Types of Concrete Sealers

Penetrating Sealers

Penetrating sealers are designed to penetrate deep into the concrete surface, forming a chemical barrier that protects against moisture and contaminants. These sealers are ideal for basements because they provide long-lasting protection without altering the appearance of the concrete. Common types of penetrating sealers include silanes, siloxanes, and siliconates. These sealers react with the concrete to create a hydrophobic (water-repellent) surface, reducing water absorption and preventing damage from freeze-thaw cycles.

Acrylic Sealers

Acrylic sealers form a protective film on the surface of the concrete, providing a clear, glossy, or matte finish. These sealers are easy to apply and dry quickly, making them a popular choice for DIY projects. Acrylic sealers are available in both water-based and solvent-based formulations, with water-based options being more environmentally friendly. While acrylic sealers provide good protection against moisture and stains, they may require more frequent reapplication compared to other types of sealers.

Epoxy Sealers

Epoxy sealers offer excellent durability and resistance to chemicals, abrasions, and moisture. These sealers create a thick, hard coating on the concrete surface, making them suitable for high-traffic areas and basements used as workshops or recreational spaces. Epoxy sealers are typically two-component systems that require mixing before application. They provide a glossy finish and are available in clear and colored options. Due to their strength and durability, epoxy sealers are often used in industrial and commercial settings.

Polyurethane Sealers

Polyurethane sealers are known for their high-performance and long-lasting protection. These sealers form a robust, protective film on the concrete surface that resists chemicals, abrasions, and UV damage. Polyurethane sealers are available in water-based and solvent-based formulations, with water-based options being less odorous and more environmentally friendly. They provide a glossy or satin finish and are highly durable, making them an excellent choice for basements exposed to heavy use and harsh conditions.

Polyaspartic Sealers

Polyaspartic sealers are a newer type of concrete sealer that offers rapid curing times and exceptional durability. These sealers form a clear, hard coating that resists moisture, chemicals, and UV damage. Polyaspartic sealers are known for their fast drying times, allowing for quicker project completion. They provide a high-gloss finish and are available in various colors. Due to their advanced performance and rapid curing, polyaspartic sealers are often used in commercial and industrial applications, but they are also suitable for residential basements.

Step-by-Step Process for Sealing a Concrete Basement Floor

Surface Preparation

Proper surface preparation is critical for achieving a successful and long-lasting seal. Begin by thoroughly cleaning the concrete floor to remove any dirt, dust, grease, or contaminants. Use a vacuum or broom to sweep the floor, followed by scrubbing with a concrete cleaner and a stiff brush. Rinse the floor with clean water and allow it to dry completely. If the floor has existing sealers, paints, or coatings, use a concrete grinder or stripper to remove them, ensuring a clean and porous surface for the new sealer.

Repairing Cracks and Imperfections

Inspect the concrete floor for any cracks, holes, or imperfections that need to be addressed before sealing. Use a concrete patching compound to fill in any gaps or cracks, smoothing the surface with a putty knife. Allow the patching compound to dry and cure according to the manufacturer’s instructions. Sand the patched areas to ensure a smooth and even surface, and vacuum up any dust or debris. Properly repaired surfaces ensure that the sealer can adhere effectively and provide optimal protection.

Etching the Concrete

Etching the concrete surface is an important step to ensure proper adhesion of the sealer. Use a concrete etching solution to open up the pores of the concrete, creating a rougher texture that allows the sealer to bond effectively. Follow the manufacturer’s instructions for applying and rinsing the etching solution. After etching, allow the floor to dry completely before moving on to the next step. Etching is particularly important for smooth or previously sealed concrete surfaces.

Applying the Sealer

Once the surface is prepared and dry, it’s time to apply the sealer. Choose a sealer that suits your needs and follow the manufacturer’s instructions for application. Use a high-quality roller or brush to apply the sealer in thin, even coats, working in small sections to ensure full coverage. For larger areas, a sprayer may be used to apply the sealer evenly. Allow each coat to dry completely before applying additional coats. Depending on the type of sealer and desired finish, multiple coats may be necessary to achieve the best results.

Curing and Drying

After applying the final coat of sealer, allow the floor to cure and dry according to the manufacturer’s instructions. The curing time can vary depending on the type of sealer and environmental conditions. Avoid walking on the floor or placing objects on it until the sealer is fully cured. Proper curing ensures that the sealer forms a strong, durable bond with the concrete, providing long-lasting protection. Once cured, the sealed floor is ready for use and offers enhanced durability and moisture resistance.

Maintenance Tips for Sealed Concrete Basement Floors

Regular Cleaning

Maintaining a clean sealed concrete basement floor is essential for preserving its appearance and longevity. Sweep or vacuum the floor regularly to remove dust and debris. Use a damp mop with a mild, pH-neutral cleaner specifically designed for sealed concrete surfaces. Avoid using harsh chemicals or abrasive cleaners that can damage the sealer. Wipe up any spills immediately to prevent staining and water damage. Regular cleaning helps to maintain the protective qualities of the sealer and keeps the floor looking its best.

Protecting the Surface

Protecting the surface of the sealed concrete floor can help prolong its lifespan and maintain its aesthetic appeal. Place mats or rugs in high-traffic areas and near entry points to catch dirt and moisture. Use furniture pads under heavy objects to avoid scratches and dents. Avoid dragging heavy items across the floor, as this can cause damage to the sealer and the concrete surface. Implementing these protective measures helps to prevent wear and tear and keeps the floor in optimal condition.

Addressing Wear and Tear

Over time, sealed concrete floors may show signs of wear and tear, such as scuffs, scratches, or chips. Address these issues promptly to prevent further damage. Touch up small areas with the same sealer used initially, following the same preparation and application steps. For larger areas or extensive damage, consider resealing the entire floor to ensure a uniform and refreshed appearance. Regular maintenance and timely repairs help to preserve the durability and protective qualities of the sealer.

Periodic Resealing

Depending on the type of sealer used and the level of foot traffic, periodic resealing may be necessary to maintain the floor’s protection and appearance. Water-based acrylic sealers may need to be reapplied every 1-3 years, while penetrating sealers and epoxy or polyurethane sealers can last 5-10 years or longer. Follow the manufacturer’s recommendations for resealing intervals and monitor the condition of the sealed floor regularly. When the protective qualities of the sealer begin to diminish, such as reduced water repellency or increased staining, it’s time to reseal the floor. Properly cleaning and preparing the surface before resealing ensures optimal adhesion and performance of the new sealer. Periodic resealing helps to maintain the longevity and effectiveness of the sealer, prolonging the life of the concrete basement floor.

Common Mistakes to Avoid

Skipping Surface Preparation

One of the most common mistakes when sealing concrete basement floors is skipping or inadequately performing surface preparation. Failing to clean, repair, and etch the surface can result in poor sealer adhesion and premature failure. Always take the time to properly prepare the concrete surface before applying the sealer.

Using the Wrong Type of Sealer

Choosing the wrong type of sealer for the concrete basement floor can lead to disappointing results. Not all sealers are suitable for basement environments or compatible with concrete substrates. Ensure that you select a sealer specifically designed for basement floors and the type of concrete you have, such as penetrating, acrylic, epoxy, or polyurethane sealers.

Applying Too Much or Too Little Sealer

Applying too much or too little sealer can affect the performance and appearance of the sealed concrete basement floor. Follow the manufacturer’s instructions for application thickness and coverage rates to ensure proper protection. Applying multiple thin coats of sealer is generally more effective than a single thick coat.

Not Allowing Sufficient Drying Time

Not allowing sufficient drying time between coats or before using the sealed floor can result in premature damage or failure of the sealer. Follow the manufacturer’s recommendations for drying and curing times, and avoid walking on or placing objects on the floor until the sealer is fully cured.

Neglecting Regular Maintenance

Neglecting regular maintenance of the sealed concrete basement floor can compromise its protection and longevity. Regular cleaning, inspections, and resealing as needed are essential for preserving the integrity of the sealer and the concrete substrate. Make maintenance a priority to ensure the continued performance and appearance of the sealed floor.

How long does it take to seal a concrete basement floor?

The time it takes to seal a concrete basement floor depends on several factors, including the size of the area, the type of sealer used, and environmental conditions. Surface preparation, including cleaning, repairing, and etching, can take several hours to a day. Applying the sealer typically requires multiple coats with drying times between each coat, ranging from a few hours to a day or more. Plan accordingly and allow sufficient time for each step of the sealing process.

How often should a concrete basement floor be sealed?

The frequency of sealing a concrete basement floor depends on factors such as the type of sealer used, the level of foot traffic, and exposure to moisture and chemicals. Penetrating sealers may need to be reapplied every 5-10 years, while acrylic sealers may require reapplication every 1-3 years. Monitor the condition of the sealed floor regularly and reseal it as needed to maintain its protection and appearance.

Can I seal a damp concrete basement floor?

It is not recommended to seal a damp concrete basement floor, as moisture trapped beneath the sealer can lead to adhesion issues and premature failure. Ensure that the concrete floor is completely dry before applying the sealer. Use a moisture meter to test the moisture content of the concrete, and allow the floor to dry thoroughly before sealing. Address any underlying moisture issues, such as leaks or drainage problems, before sealing the floor.

Can I apply a sealer over an existing sealer on a concrete basement floor?

In some cases, it may be possible to apply a new sealer over an existing sealer on a concrete basement floor. However, proper surface preparation is crucial to ensure adhesion between the layers of the sealer. Clean the surface thoroughly to remove any dirt, dust, or contaminants, and lightly etch the existing sealer to promote bonding. Test a small area first to ensure compatibility and adhesion before applying the new sealer to the entire floor.

Can I use a concrete sealer on painted or stained concrete basement floors?

Yes, certain types of concrete sealers can be used on painted or stained concrete basement floors to enhance protection and durability. However, it is essential to choose a sealer compatible with the existing paint or stain and follow the manufacturer’s instructions for application. Test a small area first to ensure compatibility and adhesion before applying the sealer to the entire floor. Additionally, proper surface preparation may be necessary to ensure adhesion and performance.

Alternative Finishes for Interior Concrete Floors – Concrete Decor

Understanding the Top 3 Basement Waterproofing Methods

A Guide to Stained Concrete Basement Floors

How to Seal Concrete Floors (with Pictures)

Concrete Floors: 5 Reasons to Stick With Grinding and Sealing

Concrete Sealer – Radon Mitigation and Waterproofing

Basement Floor Waterproofing For Concrete Floors With A Lot Of

Related articles:

- Best Way To Seal Concrete Basement Floor

- Cork Flooring For Basement Pros And Cons

- Exercise Flooring For Basement

- Good Basement Flooring Options

- Best Flooring For A Basement Bathroom

- Crumbling Concrete Basement Floor

- Concrete Basement Floor Covering

- Diagram Of Basement Floor Drain

- Pouring Basement Floor After Framing

- Painting Basement Walls And Floors