In case you're likely to complete or install the bamboo floor yourself, go out of the bamboo flooring open in the box in whatever room you're installing it in for at least 72 hours before you start the task. Attempt searching for bamboo that's been helped to fully mature at five years of growth. It is additionally 100 % natural.

Here are Images about Bamboo Flooring Manufacturing Process

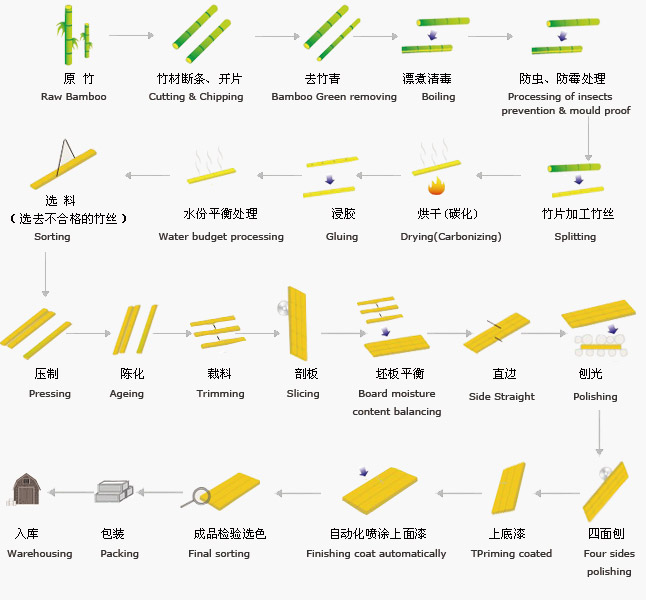

Bamboo Flooring Manufacturing Process

Vertical grain is made by installing the splits vertically and sticking them together. Strand-woven flooring is much harder compared to traditional bamboo as well as cannot be easily scratched, dented or perhaps gouged by stiletto heels, small pets as well as furniture movement. Based on the way the floor have been cured, engineered flooring is able to have its disadvantages. Another great benefit of bamboo floor is its cost.

Navigation About us Catalogue Indoor flooring “Classic” Collection

A great number of people choose to handpick bamboo flooring because of their stance of environmental awareness. As Vietnam and China are actually the major places of bamboo harvesting, they act as the key resource of bamboo flooring surfaces exporters. As a result, bamboo is thought to help more in minimizing the greenhouse gases that create the worldwide phenomenon of climate change.

Images Related to Bamboo Flooring Manufacturing Process

Bamboo Flooring Manufacturer – High Quality – Competitive Price

How Bamboo Flooring Is Made Steps To Create Bamboo Floors

How Bamboo Flooring Is Made Steps To Create Bamboo Floors

What Is Bamboo Flooring u2013 Dalamas

Bamboo Flooring Information and FAQ

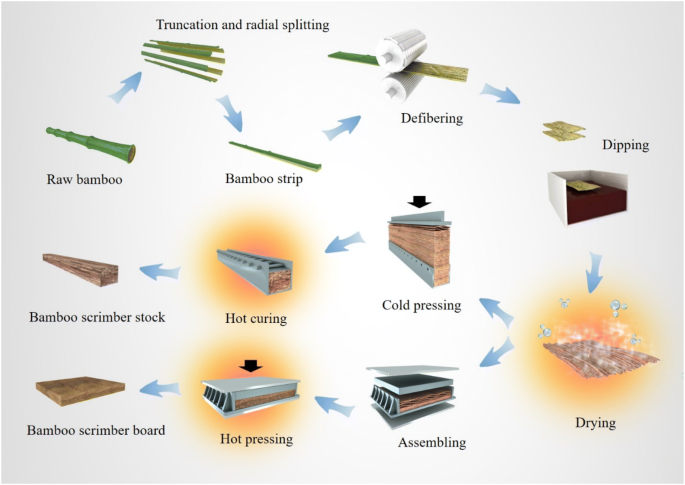

Development of bamboo scrimber: a literature review Journal of

Engineered bamboo – Designing Buildings

Strand Woven Bamboo Flooring Manufacturing Process – Durable

Bamboo Flooring production process – Eee Housing Co.,Ltd

How is bamboo flooring made? – Bamboo Flooring Blog

How Bamboo Flooring Is Made Steps To Create Bamboo Floors

How is Bamboo Flooring Manufactured? – Bamboo Flooring Blog

Related articles:

- Installing Engineered Bamboo Flooring

- Are Bamboo Floors Good For Kitchens?

- How To Clean Strand Woven Bamboo Floor

- Bamboo Kitchen Flooring Pros Cons

- Carbonized Strand Bamboo Flooring

- Distressed Bamboo Hardwood Flooring

- Petrified Bamboo Flooring

- Inexpensive Bamboo Flooring

- Chocolate Bamboo Flooring

- Red Bamboo Flooring

Bamboo flooring is widely recognized for its long-lasting durability and natural beauty, making it a popular choice for homeowners looking for a stylish and sustainable flooring option. But how is bamboo flooring made? This article will provide an overview of the bamboo flooring manufacturing process, from start to finish.

Harvesting Bamboo

The first step in the bamboo flooring manufacturing process is harvesting the bamboo. This is usually done in areas with high concentrations of bamboo, such as China, India, and Southeast Asia. The harvesting process involves cutting down the mature stalks of bamboo, which are then transported to the manufacturing facility.

The Manufacturing Process

Once at the manufacturing facility, the harvested bamboo is dried in special drying chambers. This process helps to preserve the integrity of the bamboo and prevents it from warping or cracking during the manufacturing process. After drying, the bamboo is cut into thin strips that are suitable for use in flooring. The strips are then milled into planks, which are ready for finishing.

Finishing Bamboo Flooring

The next step in the manufacturing process is finishing the bamboo flooring. This involves applying a protective coating to the planks, such as a wax or polyurethane sealer. This helps to protect the planks from wear and tear and makes them easier to clean and maintain. The planks are then cut into finished boards that are ready to be installed in homes or businesses.

Installation of Bamboo Flooring

The last step in the manufacturing process is installation. Depending on the type of bamboo flooring, installation can be done either by a professional installer or by a homeowner with some DIY experience. Professional installers will have all of the necessary tools and equipment to ensure a proper installation, while DIY homeowners may need to purchase some additional tools and materials.

FAQs About Bamboo Flooring Manufacturing Process

Q: How long does it take to manufacture bamboo flooring?

A: It typically takes about 4-6 weeks for bamboo flooring to be manufactured from start to finish. However, this can vary depending on the size of the order and other factors such as availability of materials and labor.

Q: Is bamboo flooring eco-friendly?

A: Yes, bamboo flooring is a highly sustainable material due to its fast growth rate and ability to regenerate quickly after being cut down. It also requires less energy and resources than traditional hardwood flooring during its production process.

Q: What type of maintenance is required for bamboo flooring?

A: Bamboo flooring should be swept or vacuumed regularly to prevent dirt or debris from collecting on its surface. It should also be mopped with a damp cloth and mild cleaning solution every few weeks to keep it looking its best.