Visual imperfections, contraction and extension are actually some of the issues you may have to contend with if you buy low quality flooring. When harvested, every 3 to 5 years, bamboo is subsequently constructed with improved technology producing strips, planks or tiles allowing for this unique material to be installed in the exact same fashions as other hardwood flooring material.

Here are Images about Bamboo Flooring Construction

Bamboo Flooring Construction

Time was when flooring making use of bamboo was hard to find & costly. This quality work is a combination of the quality of flooring work the company has supplied and also the professionalism of this company's people from the field workers up to the control. Pick small pieces of felt or perhaps other content under chair and table legs and other furniture legs, and do not drag furniture across the floor.

Bamboo flooring, Flooring materials, Flooring

Bamboo is an extremely challenging wood, it's more or less not as hard as hickory, but it's slightly harder compared to oak & ash. In reality, this flooring isn't a hardwood floor but a lawn cultivated in tropical weather factors ideal for that growing. You do not want install a floor just to have to replace it in a several years, so you need to select a floor that will stand approximately the test of time.

Images Related to Bamboo Flooring Construction

Gluing Down Bamboo Flooring – Tips u0026 Tricks

How Bamboo Flooring Is Made BuildDirect® Learning CenterLearning

Bamboo Flooring Installation, Installing Bamboo Floors, Wholesale

Solid Parquet Bamboo Natural Vertical Flooring – Buy Bamboo Floor

22 Dimensions ideas kitchen cabinet dimensions, kitchen cabinets

Bamboo floors

Image result for bamboo floor construction Bambú, Casa exterior

All The Things You Need To Know About Solid Bamboo Flooring

Bamboo floors

Outdoor Bamboo Bar Construction Material Flooring Panel – Buy

Introduction SpringerLink

Is It Time To Consider Bamboo Floors? Anlon Homes

Related articles:

- Bamboo Natural Flooring

- How To Clean Bamboo Floors With Vinegar

- Compressed Bamboo Flooring

- Scraped Bamboo Flooring

- Bamboo Flooring Glue Vs Floating

- Dark Mahogany Bamboo Flooring

- Natural Floors Brushed Spice Bamboo

- How To Glue Bamboo Flooring

- Bamboo Floor Repair Kit Scratches

- Bamboo Flooring Installation Problems

Bamboo flooring has become a popular choice for homeowners looking for a sustainable and durable alternative to traditional hardwood floors. This eco-friendly option is not only aesthetically pleasing but also offers many benefits in terms of durability, cost-effectiveness, and ease of maintenance. In this article, we will delve into the construction process of bamboo flooring, exploring the various stages involved in transforming bamboo into high-quality flooring material.

1. Harvesting and Selection of Bamboo:

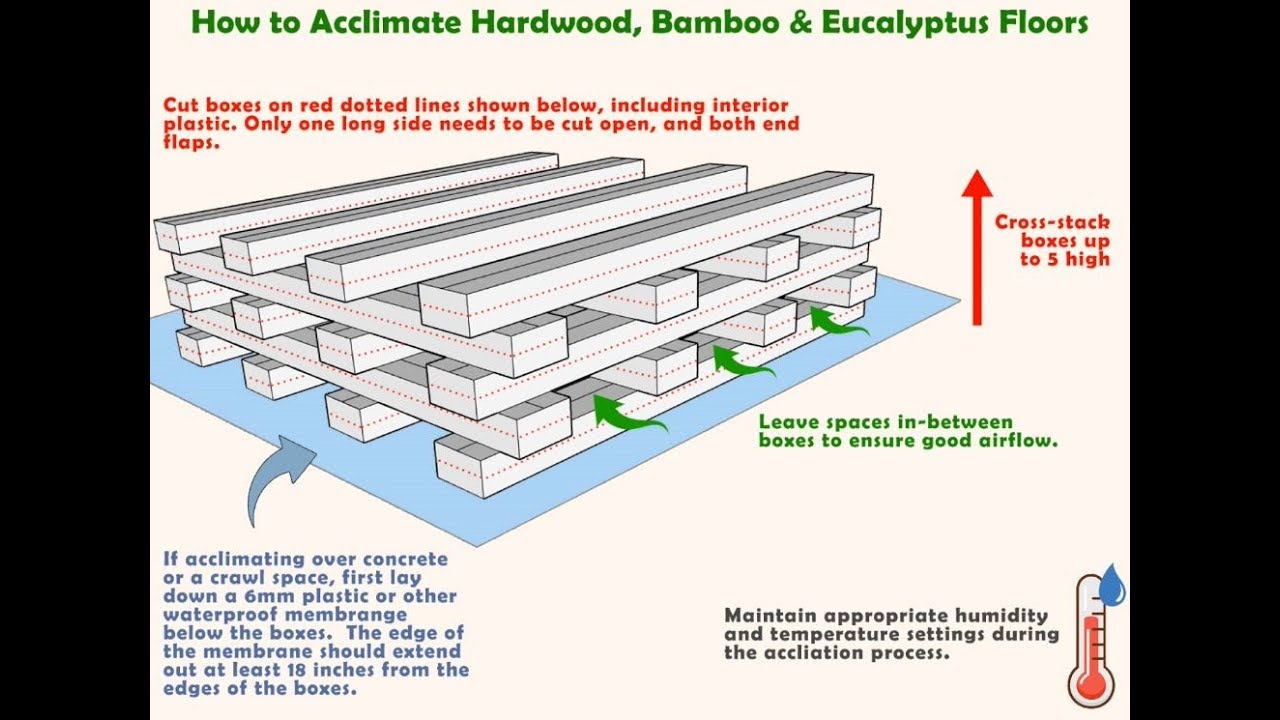

The construction of bamboo flooring begins with the harvesting and selection of bamboo stalks. Bamboo is known for its rapid growth rate, making it a highly renewable resource. The stalks are typically harvested when they reach maturity, which can vary depending on the species of bamboo. Once harvested, the bamboo stalks are carefully selected based on their quality and size to ensure uniformity in the final product.

FAQs:

Q: How long does it take for bamboo to reach maturity?

A: Bamboo can reach maturity in as little as 3-5 years, making it one of the fastest-growing plants on Earth.

2. Processing and Treatment:

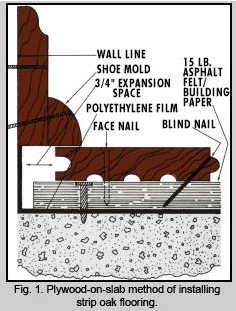

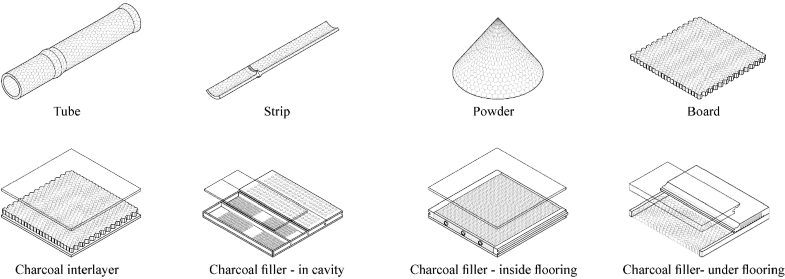

After harvesting and selection, the bamboo stalks undergo a series of processing and treatment steps to prepare them for flooring construction. The stalks are first cut into strips or planks, which can vary in width depending on the desired style of flooring. These strips are then treated with heat and pressure to remove any moisture and sugars, making the bamboo more resistant to pests and mold.

FAQs:

Q: Why is heat treatment necessary for bamboo flooring?

A: Heat treatment helps to stabilize the bamboo fibers, making them less susceptible to expansion and contraction due to changes in humidity.

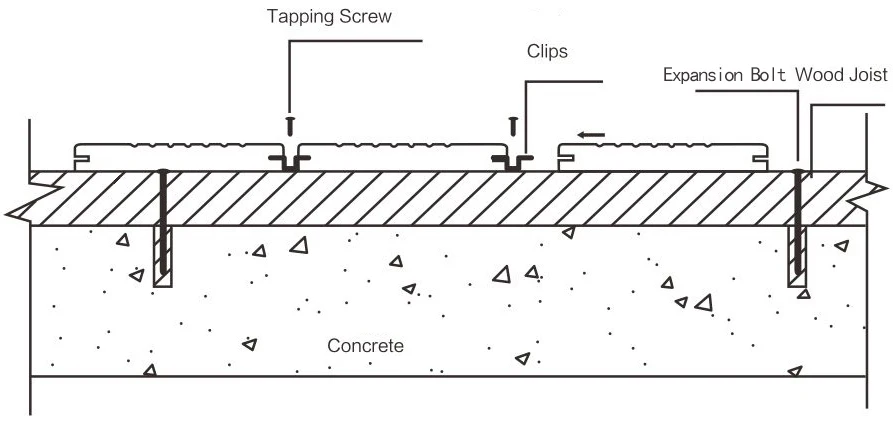

3. Lamination and Adhesive Application:

Once the bamboo strips have been processed and treated, they are ready for lamination. In this stage, multiple layers of bamboo strips are glued together using high-quality adhesive. The direction of each layer is alternated to enhance the stability and strength of the final product. The adhesive used in this process is typically environmentally friendly and free from harmful chemicals.

FAQs:

Q: Is bamboo flooring safe for indoor use?

A: Yes, bamboo flooring is safe for indoor use as long as it has been properly manufactured and treated with non-toxic materials.

4. Pressing and Cutting:

After lamination, the bamboo planks undergo a pressing process to ensure that all layers are securely bonded together. This step also helps to achieve a smooth and uniform surface finish. Once pressed, the bamboo planks are cut into standard sizes using precision cutting equipment. This ensures that each plank fits seamlessly during installation.

FAQs:

Q: Can bamboo flooring be customized to fit specific room dimensions?

A: Yes, bamboo flooring can be custom-cut to fit any room dimensions or layouts, providing a tailored solution for homeowners.

5. Sanding and Finishing:

The final stage in the construction of bamboo flooring involves sanding and finishing the planks to enhance their appearance and durability. The surface of each plank is sanded down to remove any imperfections or rough spots, creating a smooth texture. A protective finish is then applied to seal the bamboo against moisture, scratches, and UV damage.

FAQs:

Q: What types of finishes are available for bamboo flooring?

A: Bamboo flooring can be finished with oil-based or water-based coatings, each offering different levels of durability and sheen.

In conclusion, the construction of bamboo flooring involves several intricate processes that transform raw bamboo stalks into high-quality flooring material Suitable for a variety of indoor spaces. From harvesting and processing the bamboo stalks to lamination, pressing, cutting, sanding, and finishing, each step is crucial in creating a durable and visually appealing flooring product. By following these detailed construction processes, manufacturers are able to produce bamboo flooring that is not only environmentally friendly but also sustainable and long-lasting. Overall, bamboo flooring is a popular choice for homeowners looking for a sustainable and eco-friendly option. Its durability, strength, and aesthetic appeal make it a great alternative to traditional hardwood floors. Understanding the construction process of bamboo flooring can help consumers appreciate the craftsmanship and quality that goes into each plank. With proper care and maintenance, bamboo flooring can last for many years, providing a beautiful and sustainable flooring option for any home.

Overall, bamboo flooring is a durable, sustainable, and environmentally friendly option for homeowners. By understanding the intricate construction process involved in creating bamboo flooring, consumers can appreciate the craftsmanship and quality that goes into each plank. From harvesting and processing raw bamboo stalks to lamination, pressing, cutting, sanding, and finishing, each step plays a crucial role in creating a high-quality flooring product. With proper care and maintenance, bamboo flooring can last for many years, providing a beautiful and sustainable flooring option for any indoor space.