Epoxy flooring is really versatile and also is available in a multitude of styles as well. You will find two definitions of the process, one from the manufacturers of the item and that of the contractors which apply them. Achievement offers the benefits of manufacturing floors which are practical, stylish, and long-lasting at the very same time. You may as well take the time of yours to avoid errors.

Here are Images about Epoxy Floor Manufacturers

Epoxy Floor Manufacturers

Epoxy flooring is usually created by a contractor if it's a business task, but you'll find numerous different kits out there that homeowners are able to acquire to epoxy their basements as well as garages. With this quality hence you have a plan of having a sturdy flooring resistant to water, chemicals and stains as well as one which infuses a sampling of elegance.

Benefits of Industrial Epoxy Floors in Manufacturing – Florock

You'll additionally need a catalyst, which is a component of a multi part epoxy process that causes the resin to harden. High grade epoxy resin is actually employed to update surfaces, get colored consequences, protect floor surfaces against corrosion, and attain a water tight outcome. You can have some color that you wish this can blend well with your home color scheme.

Images Related to Epoxy Floor Manufacturers

Advanced Epoxy Flooring u2013 Commercial and Industrial Epoxy Flooring

Industrial Epoxy Flooring Manufacturing Plants Nationwide

Epoxy Flooring Installation ⋆ Hardwood Flooring by Gemini

Epoxy Superstore Floor Paint u0026 Industrial Coating Kits

Plexi-Chemie, Inc. u2013 Industrial u0026 Commercial Epoxy Floor Coatings

Industrial Epoxy Flooring for Manufacturers: Pros u0026 Cons

Epoxy floor coating for all industrial / commercial needs

Everlast Industrial Flooring Polished Concrete, Epoxy Floor

Ten of the worlds leading manufacturers of epoxy flooring products

4 Reasons Epoxy Flooring is Ideal – Liquid Floors, Inc

Industrial Epoxy Floor Coatings and Installation Solutions Black

Epoxy Floor Coatings: Everything You Need to Know – Florock

Related articles:

- DIY Epoxy Floor Garage

- Epoxy Flooring Systems Grand Forks

- Epoxy Flooring Nashville Tn

- Metallic Epoxy Flooring In Bangalore

- Affordable Epoxy Flooring Installers

- Epoxy Floor Paint Quality

- Epoxy Floor Paint Philippines

- Epoxy Flooring Windsor Ontario

- Epoxy Flooring Rockford Il

- Epoxy Floor Nj

Epoxy Floor Manufacturers: Providing High-Quality Flooring Solutions

Introduction:

Epoxy flooring has gained immense popularity in recent years due to its durability, versatility, and aesthetic appeal. It is a type of resin-based flooring that is commonly used in commercial, industrial, and residential settings. To ensure the best results, it is crucial to choose a reliable and reputable epoxy floor manufacturer. In this article, we will explore the world of epoxy floor manufacturers, their products, and the key factors to consider when selecting one.

I. The Role of Epoxy Floor Manufacturers:

Epoxy floor manufacturers play a vital role in the production and distribution of high-quality epoxy flooring solutions. They specialize in creating resin-based products that are designed to offer exceptional performance, longevity, and visual appeal. These manufacturers employ advanced technologies and adhere to strict quality control measures to ensure their products meet industry standards.

A reputable epoxy floor manufacturer understands the unique requirements of different environments and offers a wide range of options tailored to specific needs. They work closely with architects, contractors, and clients to provide customized solutions that meet both functional and aesthetic requirements.

FAQs:

1. Why should I choose an epoxy floor manufacturer instead of generic suppliers?

Choosing an epoxy floor manufacturer ensures that you get access to specialized expertise, high-quality products, and reliable customer service. They have in-depth knowledge about epoxy flooring systems and can provide valuable guidance throughout the selection and installation process.

2. Can I purchase epoxy flooring directly from manufacturers?

While some manufacturers offer direct sales to customers, many prefer working through authorized distributors or contractors. This allows for better support during installation and post-sales service.

II. Product Range:

Epoxy floor manufacturers offer an extensive range of products to cater to various applications. From simple solid color coatings to intricate decorative designs, they provide solutions that can transform any space. Let’s take a closer look at some popular epoxy flooring options available from these manufacturers:

1. Epoxy Coatings:

Epoxy coatings are the most common type of epoxy flooring. They consist of a base resin and a hardener that chemically react to form a strong, adhesive surface. Epoxy coatings are available in different thicknesses and can be customized with various additives, such as anti-slip agents or UV resistance, depending on the specific requirements of the project.

FAQs:

3. Are epoxy coatings suitable for residential use?

Yes, epoxy coatings are an excellent choice for residential applications. They offer durability, easy maintenance, and a variety of design options to enhance the aesthetics of your home.

4. Can epoxy coatings be applied to existing concrete floors?

Yes, epoxy coatings can be applied to existing concrete floors after proper surface preparation. This makes them a cost-effective solution for refurbishing old or damaged floors.

2. Epoxy Mortar Systems:

Epoxy mortar systems are designed to withstand heavy traffic, impact, and chemical exposure. They consist of a mixture of epoxy resin and sand or quartz aggregate, creating a durable and highly resistant floor surface. These systems are commonly used in industrial settings such as manufacturing plants, warehouses, and automotive facilities.

FAQs:

5. How thick should an epoxy mortar system be?

The thickness of an epoxy mortar system typically ranges from 1/4 inch to 3/8 inch (6-9 mm). However, it can be adjusted based on the level of traffic and specific needs of the facility.

6. Are epoxy mortar systems suitable for areas with high moisture content?

Yes , epoxy mortar systems are suitable for areas with high moisture content. They can effectively prevent moisture from seeping into the substrate and causing damage to the floor. Additionally, some epoxy mortar systems also have moisture vapor transmission properties, allowing them to be applied over damp concrete surfaces.

3. Metallic Epoxy Floors:

Metallic epoxy floors are a popular choice for decorative and high-end applications. They create a unique, glossy, and three-dimensional effect that resembles molten metal or marble. Metallic epoxy floors are highly customizable, allowing for endless design possibilities. They are commonly used in retail spaces, restaurants, hotels, and residential properties.

FAQs:

7. Can metallic epoxy floors be installed over existing flooring?

Yes, metallic epoxy floors can be installed over existing flooring, including concrete and tile. However, proper surface preparation is crucial to ensure adhesion and durability.

8. How long does it take to install a metallic epoxy floor?

The installation time for a metallic epoxy floor depends on the size of the area and the complexity of the design. On average, it can take anywhere from two to five days to complete the installation process.

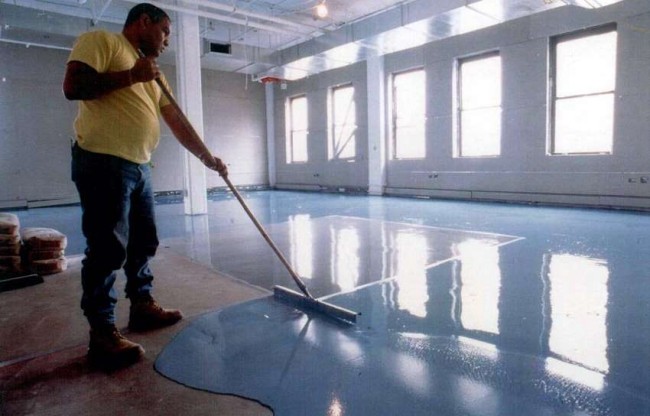

4. Self-Leveling Epoxy Floors:

Self-leveling epoxy floors are ideal for areas that require a smooth and seamless finish. They are commonly used in commercial spaces such as hospitals, laboratories, and showrooms. Self-leveling epoxy floors are easy to clean, highly durable, and resistant to chemicals and abrasion.

FAQs:

9. Can self-leveling epoxy floors be installed over uneven surfaces?

No, self-leveling epoxy floors require a level substrate for proper installation. Any unevenness or imperfections in the substrate should be addressed before applying the self-leveling epoxy material.

10. Are self-leveling epoxy floors suitable for areas with heavy equipment or machinery?

Yes, self-leveling epoxy floors can withstand heavy equipment and machinery. They are designed to be highly durable and resistant to impact, making them suitable for industrial environments.

These are just a few examples of the wide range of epoxy flooring options available from manufacturers. It’s important to consult with professionals to determine the best solution for your specific needs and requirements. Epoxy flooring systems offer a variety of options for different needs and environments. Some common types include:

1. Epoxy Coating Systems:

Epoxy coating systems are a popular choice for industrial and commercial spaces. They provide a durable, high-performance surface that is resistant to chemicals, abrasion, and impact. Epoxy coating systems can be applied over concrete or other substrate materials to create a smooth and seamless finish.

2. Epoxy Mortar Systems:

Epoxy mortar systems are ideal for areas with high moisture content. They can effectively prevent moisture from seeping into the substrate and causing damage to the floor. Additionally, some epoxy mortar systems also have moisture vapor transmission properties, allowing them to be applied over damp concrete surfaces.

3. Metallic Epoxy Floors:

Metallic epoxy floors are a popular choice for decorative and high-end applications. They create a unique, glossy, and three-dimensional effect that resembles molten metal or marble. Metallic epoxy floors are highly customizable, allowing for endless design possibilities. They are commonly used in retail spaces, restaurants, hotels, and residential properties.

4. Self-Leveling Epoxy Floors:

Self-leveling epoxy floors are ideal for areas that require a smooth and seamless finish. They are commonly used in commercial spaces such as hospitals, laboratories, and showrooms. Self-leveling epoxy floors are easy to clean, highly durable, and resistant to chemicals and abrasion.

When considering epoxy flooring options, it’s important to consult with professionals to determine the best solution for your specific needs and requirements. Proper surface preparation is crucial for ensuring adhesion and durability, so any existing flooring or unevenness in the substrate should be addressed before installation. The installation time for a metallic epoxy floor can vary depending on the size of the area and complexity of the design, but on average it can take anywhere from two to five days to complete the process.

Overall, epoxy flooring systems offer a range of benefits including durability, resistance to various factors, and aesthetic appeal. They are a versatile option for many different environments and can be customized to meet specific design preferences.