The reasons for this vary from the point that the polished concrete floors need a lot of specialized expertise to the fact that many folks prefer to consider the entire practice of improving the concrete floor as a process that is not suited to the day person. Combine this with concrete etching and also you can have a very artful look on your floors.

Here are Images about Typical Concrete Floor Construction

Typical Concrete Floor Construction

Each time you will undertake maintenance work for the polished concrete floors of yours, you need spending merely a fraction of money as as opposed to other flooring available choices. In domestic ways polished concrete floors are actually chosen for its good looks, but in manufacturing settings it is recommended due to practicality; these flooring surfaces are additionally really functional.

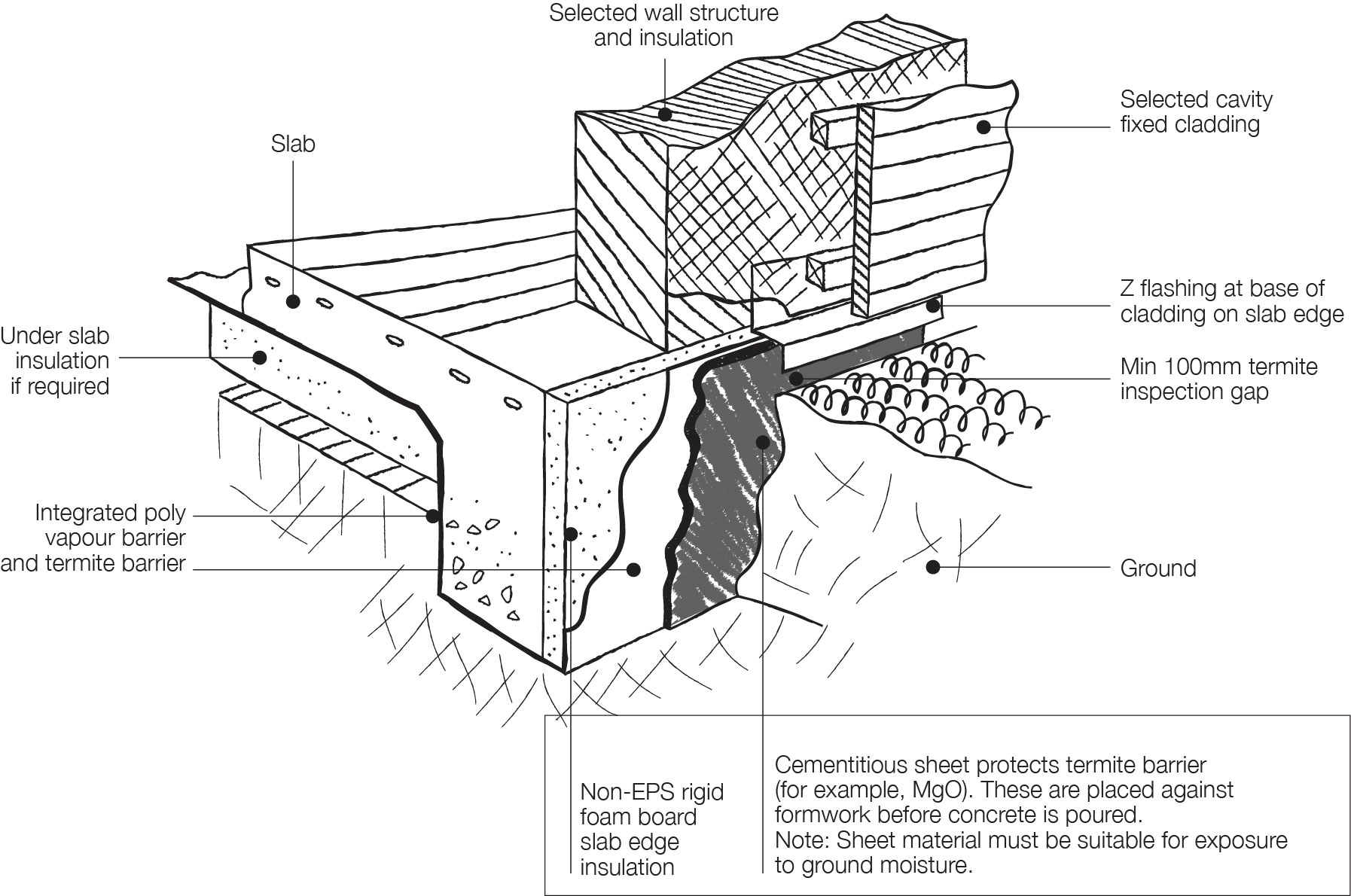

Concrete slab floor construction BRANZ Renovate

Polished concrete floors are now being noticed when the faster subject matter which is actually both highly functional and also decorative for public buildings. You can combine it in various other surfaces to compliment your flooring option. Customers often have various preferences. The idea of a lifeless greyish concrete floor has been replaced with delightful surfaces that can be as granite, marble, and even tile.

Images Related to Typical Concrete Floor Construction

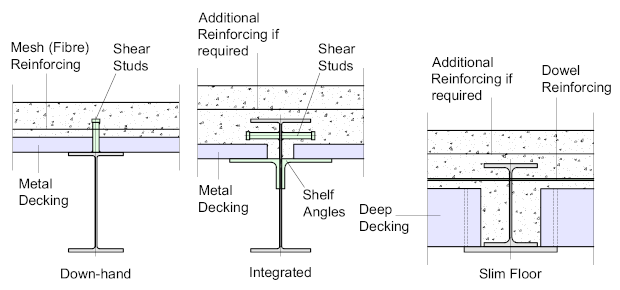

Concrete Composite Floors u2013 Construction Details u2013 Structural Detailer

Concrete slab floors YourHome

Concrete floor – Podovi Grupa

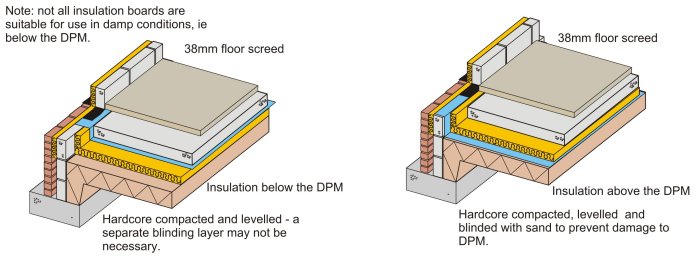

Evolution of Building Elements

What Is Floating Slab Floating Slab Construction How to Build a

Building Guidelines Drawings. Section B: Concrete Construction

How to Evaluate Cracks in Poured Concrete Slabs

Evolution of Building Elements

Concrete Floor Slabs Concrete Construction Magazine

Construction Joints in Concrete Slabs – Concrete Network

Floor Framing u0026 Structure

Building Guidelines Drawings. Section B: Concrete Construction

Related articles:

- Concrete Floor Resin Coating

- Concrete Floor Paint Preparation

- Stained Concrete Floor Designs

- How To Paint A Concrete Floor Inside

- Concrete Floor In Garage

- Polished Concrete Floor Ideas

- Gypsum Concrete Floor Underlayment

- Polishing Concrete Floor By Hand

- Concrete Floor Paint Prep

- Polished Concrete Floors For Patios

Typical Concrete Floor Construction

Concrete floor construction is a common and essential part of many building projects. It is an important element of the structure, providing a solid foundation for other materials to be installed on top. In order to construct a strong and long-lasting concrete floor, there are several steps that must be taken in order to ensure that the job is done correctly. This article will provide an overview of the typical concrete floor construction process, as well as some helpful tips for ensuring a good result.

Preparation

Before any concrete can be laid, the area must first be prepared. This includes removing any existing debris or materials from the area, and ensuring that the ground is level and free from obstructions. The surface should then be treated with a bonding agent such as epoxy or polyurethane in order to ensure a strong bond between the concrete and its substrate. Once this has been completed, it’s time to start laying the concrete.

Laying the Concrete

The next step is to lay the concrete itself. This should be done according to the instructions provided by the manufacturer, using a level surface and adequate support for the weight of the concrete. It’s important to ensure that there are no air pockets or gaps in between slabs, as these can lead to weak spots in the floor or even structural failure. Once all of the concrete has been laid, it should be allowed to cure for at least 24 hours before any further work is done on it.

Finishing Touches

Once the concrete has cured completely, it should then be sealed with a sealant or waterproofing material in order to protect it from water damage and staining. Depending on where it will be used, additional finishes may need to be applied such as an anti-slip coating or decorative aggregate material. Once all of these steps have been completed, it’s time to enjoy your new concrete floor!

FAQs about Concrete Floor Construction

Q: How long does it take to construct a typical concrete floor?

A: The time required for constructing a typical concrete floor will vary depending on several factors such as size of the area being covered and complexity of the design. Generally speaking however, it takes around 2-3 days to complete most floors from start to finish.

Q: What materials are needed for constructing a concrete floor?

A: The materials needed for constructing a typical concrete floor include cement mix, sand, gravel, bonding agent (such as epoxy or polyurethane), sealant/waterproofing material and any finishes that may be desired (such as anti-slip coating).

Q: How do you ensure that your concrete floor is level?

A: It’s important that you check for levelness before you begin laying your concrete. You can do this using either a laser leveler or simply by using a long straight edge across your surface area and checking for discrepancies with a spirit level. Doing this will help you avoid any potential issues with unevenness or weak spots in your finished product.

Q: Can I add finishing touches after my floor has been laid?

A: Yes! You can add finishing touches after your floor has been laid – such as adding an anti- Slip coating or decorative aggregate material. However, it’s important to make sure that you wait until the concrete has fully cured before doing so.