The polished floors are among the best techniques to maintain a good flooring while in trying to keep with' green' observance because concrete flooring doesn't require fact of other raw materials or maybe substances, which would otherwise put a stress on the planet. Conversely, concrete pulls the heating coming from the sun in the winter months, so your flooring continues to be hot.

Here are Images about Prefabricated Concrete Floor Systems

Prefabricated Concrete Floor Systems

In certain cases, almost all that will be required is actually an easy rebuffing of the flooring with some polishing compound. Remember it is crucial to use concrete floor sealers to help look after the surface area. It's accurate that one requires quite some basic approach of trying to look after these concrete floors but there are particular facts about maintenance that need to be kept in mind.

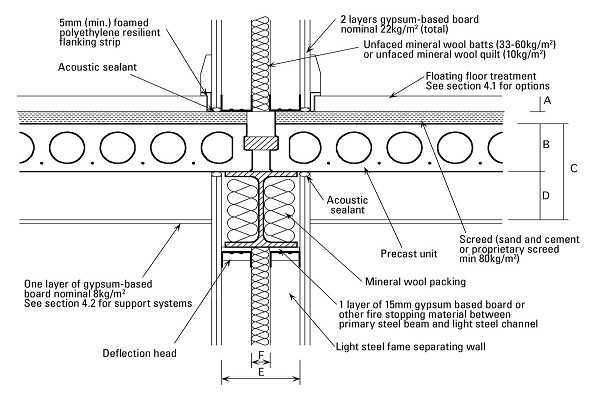

Hollowcore Flooring – Precast Concrete from Mannok

This particular kind of system works to stop long lasting degeneration of finished concrete floors. No matter what may leak on it or be pulled across it, concrete floors is virtually indestructible. When you're thinking that you want to have further alternatives than simply a glossy surface and color to work into your design goals, then polished concrete is still the method to go.

Images Related to Prefabricated Concrete Floor Systems

Precast Omnia Floor Slab Precast Concrete Product Keegan Precast

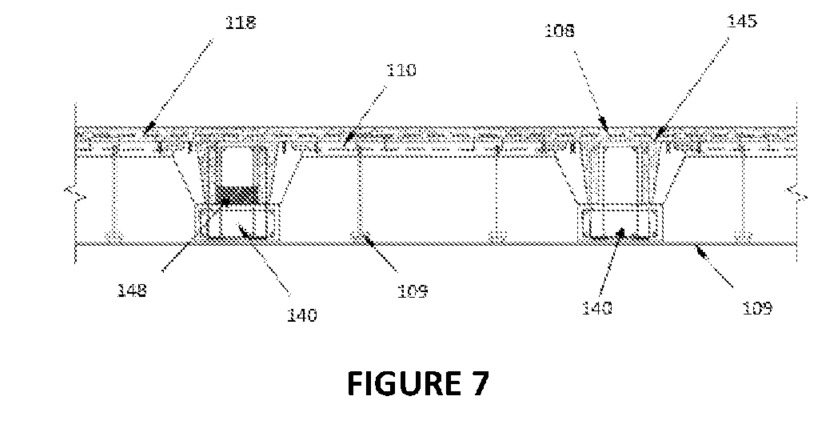

Precast concrete formwork, floor system and a method of

Lightweight Concrete Floor Systems – Thickness, Uses – The Constructor

Lighter, Stronger Precast Concrete Floor System – NPCA

Reinforced concrete precast core floor slab – HOLLOWCORE – concast

Taxonomy – Precast concrete floor with reinforced concrete topping

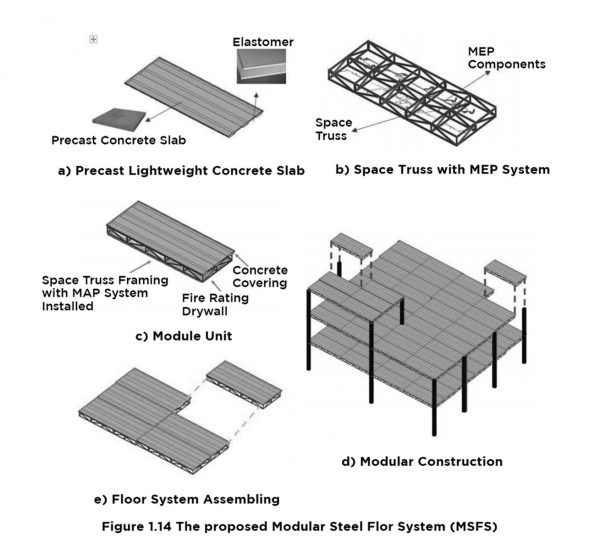

UBC researcher finds modular steel flooring panels can speed up

Precast Concrete – an overview ScienceDirect Topics

STRUCTURE magazine Creating an Opening in Existing Floors

Rhino Concrete

Precast Concrete Beams and Slabs Engineering For Change

Floor systems – SteelConstruction.info

Related articles:

- White Mold On Concrete Floor

- Polished Concrete Floor

- Polished Concrete Floor Cleaning

- Staining Concrete Floors Indoors Yourself

- Flooring Options For Concrete Floors

- White High Gloss Concrete Floors

- Acid Stain Concrete Floors DIY

- Redo Patio Concrete Floor

- Interior Concrete Floor Ideas

- Gloss Concrete Floor Paint

Prefabricated concrete floor systems are a highly effective and cost-efficient way to construct a durable, reliable, and long-lasting floor. These systems are designed to provide superior strength, stability, and longevity in any type of building or structure. They are also ideal for any situation where time, cost, or labor savings is a priority. Prefabricated concrete floors have been used for many years in both residential and commercial projects.

What are Prefabricated Concrete Floors?

Prefabricated concrete floors are precast concrete slabs that are designed to fit your exact specifications. These slabs are cast in controlled environments and then shipped to the job site where they can be quickly installed. The precast concrete slabs can be customized to meet any structural requirements and can be tailored to fit any application.

Benefits of Prefabricated Concrete Floors

Prefabricated concrete floors offer numerous benefits over traditional poured-in-place concrete flooring. They provide a superior level of strength and stability, as well as better thermal insulation properties. Prefabricated concrete floors also have improved resistance to cracking, shrinking, and warping due to their pre-tensioned construction process. Additionally, prefabricated concrete floors can be installed in significantly less time than traditional concrete floors, resulting in significant cost savings for the builder or owner.

Installation of Prefabricated Concrete Floor Systems

Prefabricated concrete floor systems can typically be installed quickly and easily with minimal disruption to existing structures and landscaping. The installation process begins with the placement of the precast slabs on the prepared subgrade. Next, the slabs are secured together using steel reinforcement rods and concrete grout. Finally, the finished surface is sealed for further protection against moisture and wear.

Advantages of Prefabricated Concrete Floor Systems

Prefabricated concrete floor systems offer several advantages over traditional poured-in-place concrete flooring. These include superior structural integrity, improved thermal insulation, better resistance to cracking, shrinking, and warping due to their pre-tensioned construction process. Additionally, prefabricated concrete floor systems are significantly faster and more cost-effective to install than traditional poured-in-place concrete floors.

Conclusion

Prefabricated concrete floor systems are an excellent choice for both residential and commercial projects due to their superior strength, stability, and longevity. They also offer faster installation times and significant cost savings compared to traditional poured-in-place concrete floors. With so many benefits, prefabricated concrete floors are becoming increasingly popular among builders and owners alike.