Just before installing any covering to your concrete floor, it must be free and clean of any debris which might stop bonding, such as dirt, sealer or oil. The flooring is able to complement the kitchen, creating a spectacular masterpiece. No trees are actually cut down when concrete is actually made, less power is made to manufacture it as opposed to various other flooring sorts, and concrete flooring does not contain volatile organic compounds.

Here are Images about Concrete Floor Epoxy Filler

Concrete Floor Epoxy Filler

Occasionally grease, other substances or oil can stain concrete floor. The one thing that is going to scrape a concrete floor is a jackhammer. They are okay to be reinforced so as to be strong enough to carry the weight of a truck. Dying is not the single style choice for polished concrete flooring. The dust as well as dirt doesn't follow the floor, like it lets you do with carpet.

Epoxy vs. Polyurea Joint Fillers: Which is best? – Concrete Decor

Every time you are going to undertake maintenance work for the polished concrete floors of yours, you want spending basically a portion of cash as as opposed to other flooring available choices. In domestic settings polished concrete floors are actually chosen for its good looks, but in industrial situations it is recommended due to practicality; these flooring surfaces are also really functional.

Images Related to Concrete Floor Epoxy Filler

Epoxy Concrete Patch Repair Damaged Plant Floors u0026 Expansion Joints

Epoxy Damaged Concrete Repair Concrete Crack Repair Epoxy Jemkon

TuffPatch Concrete Repair Kits

DIY Epoxy Concrete Crack Repair – What I use – How I Repair Concrete

Epoxy Flooring Cost 2021

High strength anchored epoxy paste epoxy repair concrete cracks

FAST SET EPOXY PATCH KIT, 1 u0026 2 GAL

Concrex® Epoxy Resin Mortar u2013 Concrete Hole Repair Repair

HyperFLEX Epoxy Flexible Membrane Concrete Wood Low Temp 40°F 100% Solids

HyperREZ UV Low Temp 40°F High Build Epoxy Concrete Floor Coating 100% Solids

Concrete Pore Filler / Epoxy Repair Mortar – CLEAN TECH ERM, CLEAN

How to repair epoxy coating failure? Duraamen

Related articles:

- Concrete Floor Resin Coating

- Concrete Floor Paint Preparation

- Stained Concrete Floor Designs

- How To Paint A Concrete Floor Inside

- Concrete Floor In Garage

- Polished Concrete Floor Ideas

- Gypsum Concrete Floor Underlayment

- Polishing Concrete Floor By Hand

- Concrete Floor Paint Prep

- Polished Concrete Floors For Patios

Concrete floor epoxy filler is a versatile and durable solution for repairing cracks, holes, and imperfections in concrete surfaces. Whether you are looking to restore the appearance of your concrete floor or enhance its durability and longevity, epoxy filler is a cost-effective and long-lasting option. In this article, we will explore the benefits of using concrete floor epoxy filler, how it works, application tips, and frequently asked questions about this popular product.

Benefits of Concrete Floor Epoxy Filler:

1. Durability: Epoxy filler is known for its exceptional durability and strength. Once applied, it forms a tough bond with the concrete surface, creating a seamless repair that can withstand heavy foot traffic, vehicle traffic, and other types of wear and tear.

2. Versatility: Concrete floor epoxy filler can be used to repair a wide range of imperfections, including cracks, spalls, pits, and holes. It can also be used to level uneven surfaces and create a smooth finish on concrete floors.

3. Aesthetic Appeal: Epoxy filler comes in a variety of colors to match the existing concrete floor or create a custom look. This allows you to achieve a seamless repair that blends in seamlessly with the surrounding area.

4. Cost-Effective: Compared to replacing an entire concrete floor or hiring professional contractors for repairs, using epoxy filler is a cost-effective solution that can save you time and money.

How Concrete Floor Epoxy Filler Works:

Concrete floor epoxy filler is typically a two-component system consisting of an epoxy resin and a hardener. When mixed together, these components chemically react to form a strong adhesive bond that adheres to the concrete surface.

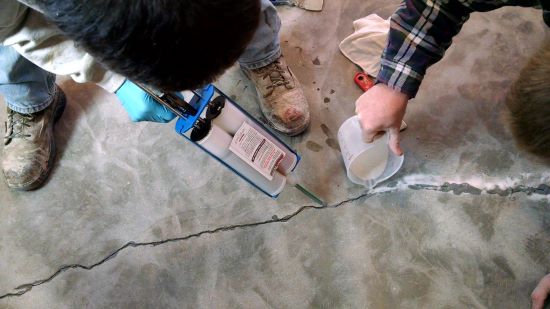

To apply epoxy filler, first clean the damaged area by removing any loose debris or contaminants. Then, mix the epoxy resin and hardener according to the manufacturer’s instructions and apply it to the damaged area using a trowel or putty knife. Smooth out the surface to create a seamless repair and allow the filler to cure according to the recommended drying time.

Once cured, the epoxy filler creates a durable and long-lasting repair that restores the integrity of the concrete surface. It provides protection against moisture penetration, abrasion, chemicals, and other forms of damage, extending the life of your concrete floor.

Application Tips for Concrete Floor Epoxy Filler:

1. Proper Surface Preparation: Before applying epoxy filler, make sure the concrete surface is clean, dry, and free of any contaminants such as oil, grease, or dirt. This will ensure proper adhesion and a successful repair.

2. Mix Thoroughly: When mixing epoxy resin with hardener, be sure to follow the manufacturer’s instructions carefully and mix the components thoroughly to ensure proper curing and bonding.

3. Work Quickly: Epoxy filler has a limited working time before it begins to cure, so work quickly when applying it to avoid premature drying or uneven application.

4. Allow Sufficient Drying Time: To achieve optimal results, allow the epoxy filler to cure for the recommended drying time before subjecting it to foot traffic or other forms of use.

Frequently Asked Questions about Concrete Floor Epoxy Filler:

Q: Can I apply epoxy filler on my own?

A: Yes, epoxy filler is designed for DIY applications and can be easily applied by following the manufacturer’s instructions carefully.

Q: How long does epoxy filler last?

A: Epoxy filler is known for its durability and long-lasting performance. With proper application and maintenance, it Can last for many years without needing repairs or replacements.

Q: Can epoxy filler be used on all types of concrete surfaces?

A: Epoxy filler is suitable for most concrete surfaces, including floors, walls, and countertops. However, it is important to check the manufacturer’s recommendations and ensure compatibility with the specific type of concrete you are working with.

Q: Is epoxy filler resistant to chemicals and stains?

A: Yes, epoxy filler is highly resistant to chemicals, stains, and other forms of damage, making it an ideal choice for protecting and repairing concrete surfaces in industrial, commercial, and residential settings.

In conclusion, concrete floor epoxy filler is a versatile and cost-effective solution for repairing damaged concrete surfaces. By following proper application techniques and maintenance practices, you can achieve a seamless repair that restores the integrity and durability of your concrete floor. Whether you are dealing with cracks, chips, or other forms of damage, epoxy filler provides a durable and long-lasting solution that enhances the appearance and performance of your concrete surface. Additionally, epoxy filler offers a wide range of benefits such as chemical resistance, stain resistance, and durability, making it suitable for various applications in residential, commercial, and industrial settings. With proper surface preparation, mixing, application, and drying time, you can ensure a successful repair that prolongs the life of your concrete floor and maintains its aesthetic appeal.

Overall, concrete floor epoxy filler is a reliable and effective solution for repairing and protecting concrete surfaces. With its long-lasting performance and easy application process, it is a popular choice for homeowners and professionals looking to maintain the integrity and longevity of their concrete floors. Whether you are dealing with minor cracks or major damage, epoxy filler can provide a seamless repair that enhances the overall quality and durability of your concrete surface. If you are considering using epoxy filler for your concrete floor, be sure to do your research and choose a high-quality product that is suitable for your specific needs. By following the manufacturer’s instructions and taking proper care of your repaired surface, you can enjoy the benefits of a durable, long-lasting, and aesthetically pleasing concrete floor for many years to come.